Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Novedge Webinar #88 Q&A: Power Surfacing for SolidWorks with nPower

September 28, 2013 5 min read

Here are the answers to all the questions you asked during Novedge Webinar #88: Power Surfacing for SolidWorks with nPower that the nPower team could not answer during the live broadcast.

Q: Can I set a dimension to thicken?

A: In the current version, you cannot set a specific thickness dimension (this is a feature we are working on for future versions). You currently have to specify the thickness as a percentage of the average edge length.

Q: How do I manage parting lines for a molded part?

A: If what you mean is to start with a parting line (NURBS curve) and build from it, then you can refer to our documentation on surface replacement. The best way to manage those parting lines is to use the boundary definition functionality (as we demonstrated during the session) to make a surface boundary along the desired parting line.

Q: What does holding the "A" key do again?

A: It stands for add geometry, so the add key, when pressed, will add an extruded section while you are manipulating objects with the triad / manipulator (if you have a face selected). Or it will add an edge loop if an edge is selected.

Q: Could you show some curvature combs on the surface so we can see the quality of the surface?

A: We showed the zebra striping during the demo. Of course, you could also show the curvature combs (to display surface quality), but we just didn’t know where to quickly find the surface combs feature during the demo. The Power Surface bodies are class A surfaces, so they will have good surface continuity.

Q: Is the surface around the star points G3 continuous, or just G2?

A: We have a patent pending algorithm for dealing with the continuity at star points. It will be G2 continuous up to right near the star point. It will be G1 (or tangent) continuous right at the star point. Increasing the conversion quality will shrink down the area that is G1 continuous and maintain a greater area of G2 continuity.

Q: Any general thoughts/strategies about how to begin? From sketches, primitives, what shape primitives for what final shapes, etc.

A: How you begin depends on the type of object you are modeling, but also personal preference. If your object is generally shaped like one of the primitives (for instance, it is helpful to choose the torus shape if you are modeling a ring). If your object has a defined contour that you want to match, use a sketch (like we did for the spoon). Watch some of our video tutorials to see how we model different types of objects.

Q: What was the difference between weighting points on the handle and pulling the point on the spoon end?

A: Pulling the points on the spoon will maintain the surface continuity (it will stay rounded or curvature continuous). When you weight a point at 100% or an edge, that allows you to break the continuity and it becomes sharp. If you weight it using a partial weight (less than 100%) then you increase the curvature or roundness at that point. The higher the weight will give a small fillet like shape, and a larger value with give a more rounded fillet like shape.

Q: Do u have any reseller channel(s)?

A: Yes, we have resellers around the world (and the list continues to grow). As a Gold Partner product, Power Surfacing is getting visibility to the wide SolidWorks reseller community. We have a list of our resellers on the reseller page on our website.

Note of the Editor: Novedge is a NPower reseller. We are authorized to sell nPower products online worldwide and we offer a Best Price Guarantee.

Q: How does this plug-in vary from T-Splines, 3Shaper, Z-Brush…?

A: The Power Surfacing plugin is much better integrated into SolidWorks than T-Splines was (we support full creation and editing within SolidWorks). But in terms of the technology, T-Splines is similar. We use Pixar SubD mathematics. T-Splines uses a different methodology. I’m not familiar with 3Shaper, but Z-Brush is a high poly modeler (which is a sculpting modeler using different technology). It creates a very dense mesh, so the model is much heavier. So different techniques (like paint brushing / sculpting) are used.

Q: I have a question related to the Thicken command for surfaces: what does the percentage in the thicken command stand for? For example: If I type -10% would it be 10% of 1 inch? And if I'm working in mm would it be 0.1mm. Thanks!

A: The percentage relates to the average size of the edges in your Power Surfacing body.

Q: Are there any plans on further improving selection tools where you could keep adding connected entities (such as faces or edges) by pressing a keyboard key?

A: Yes (in an upcoming release)

Q: How well do you work with scanned in data?

A: The current version doesn’t really support scanned data very well. However, we are developing a Power Surfacing addon / extension that supports importing scanned meshes and allows the user to create the Power Surface on top of the scanned mesh. If you are interested in this new product, please contact us for more information.

Q: Can you take some old SW parts and bring in the dumb solid to make sub-d?

A: We have a tool for editing existing SolidWorks solids and surfaces as Power Surfacing bodies (and then you can convert them back into SolidWorks solids/surfaces). It works well on fairly simple shapes. We have some extensive documentation on this particular feature that is accessible through our product documentation.

Q: Could you make a sweep and convert it to sub-d?

A: Yes, this is similar to what we showed with the cylinder (which we converted to SubD). Again, you can see the documentation here.

Q: Are educational discounts available for Power Surfacing? I teach in an industrial design department and this would be a good addition to our curriculum. I have been teaching Rhino/T Splines/TSelements for a few years now, but this is more streamlined.

A: Yes, the educational price is $195. We also offer volume discounts for schools.

Q: Can I match an existing surface or edge?

A: You can reference an existing SolidWorks surface and edit it as a Power Surface body. But if you are referring to constraining a Power Surface to an existing SolidWorks surface, this is something that we are working on for a future release.

Q: Are the sharp edges of the thicken controllable? Does a thicken always make creased edges?

A: The thicken command produces sharp / creased edges (where the offset surface joins with the original surface). But you can remove the creasing (through a simple command) or you change the weighting so that it is rounded (filleted).

Q: Is there radial symmetry?

A: Not in the current version, but that is something we are working on. It is also achievable using the current version (using the SolidWorks radial copy). Paul McCrorey demonstrated this on a wheel model (which will be posted on our web site in the future).

Q: What software if any is required for 3D printing? Can SolidWorks be used? What about Vectorworks?

A: Power Surfacing produces water tight, 3D printing compliant models. You can export STL files for 3D printing, and many 3D printers directly support the native SolidWorks format. So it is pretty easy to 3D print Power Surfacing models (and we have produced a few 3D prints ourselves). If you can export a Vectorworks model to OBJ or FBX format, then we can read it into SolidWorks and send it to 3D printers. There is probably a much more direct way of getting your Vectorworks models to 3D printers.

Looking to own your own copy of Power Surfacing for SolidWorks? Check Novedge for the best price. And don't forget to take a look at the rest of nPower's line of products.

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

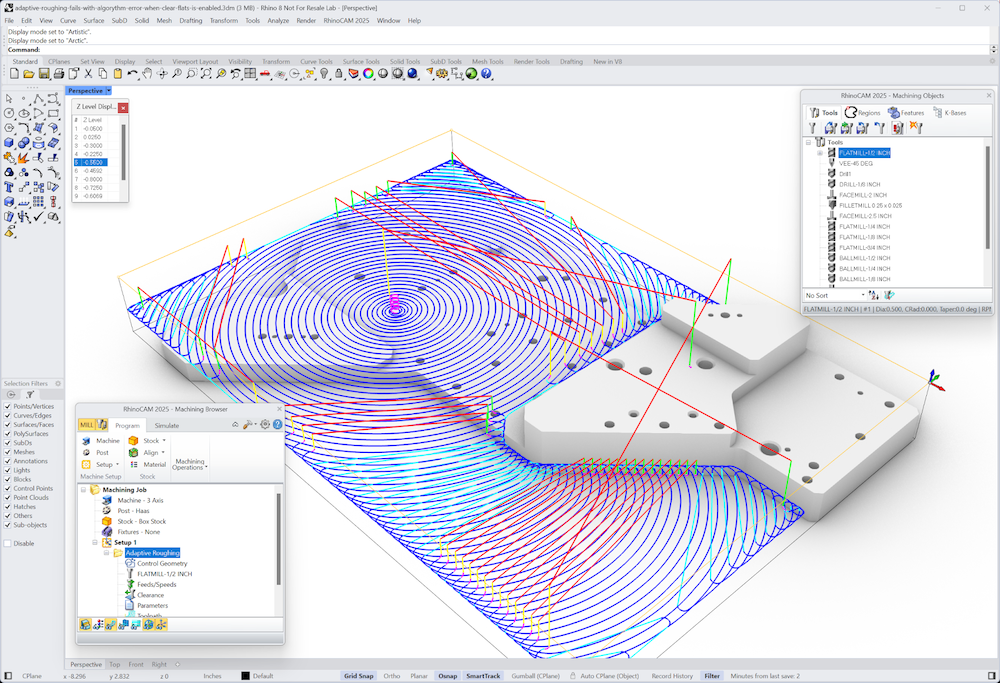

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …