Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Introducing the Latest Innovations from MecSoft Corporation

MecSoft Corporation, a pioneer in the development of industry-leading Computer Aided Manufacturing (CAM) software solutions, has unveiled the much-anticipated RhinoCAM 2025 and VisualCAD/CAM 2025. These latest releases are set to redefine efficiency and precision in the CAM industry, offering users enhanced features that streamline machining processes and expand capabilities.

RhinoCAM 2025: Elevating CAM Integration with Rhino 8

RhinoCAM 2025 is the newest version of MecSoft's fully integrated CAM plug-in for Rhino 8, the renowned 3D modeling software from McNeel. This powerful combination allows designers and engineers to perform intricate CAM programming within the familiar Rhino interface, eliminating the need for data translation and providing a seamless workflow from design to manufacturing. With advanced machining strategies and enhanced functionality, RhinoCAM 2025 takes full advantage of Rhino 8's robust modeling environment to deliver unparalleled precision and control.

VisualCAD/CAM 2025: A Comprehensive Standalone Solution

For those seeking an all-in-one CAD and CAM solution, VisualCAD/CAM 2025 stands as MecSoft's independent offering. Built on MecSoft's free CAD program, VisualCAD, this suite provides users with a complete set of modeling and machining tools without the need for additional software. VisualCAD/CAM 2025 is ideal for users who require a powerful, yet accessible platform for designing and manufacturing parts in a variety of industries.

Key Enhancements in the 2025 Releases

Both RhinoCAM 2025 and VisualCAD/CAM 2025 come packed with significant improvements that enhance functionality and user experience. Below are some of the key enhancements users can look forward to:

Feed Rate Optimization for Planar Toolpaths

The 2025 releases introduce feed rate optimization for planar toolpaths in both 2-axis and 3-axis machining. This feature intelligently adjusts the feed rate based on the cutting conditions, ensuring optimal material removal rates while prolonging tool life. By automatically varying the feed rate, users can achieve smoother cuts and reduce machining times.

Faceting Control for Improved 3-Axis Surface Machining

Faceting control is a significant enhancement that allows users to dictate the level of surface faceting during 3-axis surface machining. This refinement leads to improved surface finishes and greater accuracy in the final product. With better control over the faceting parameters, machinists can produce parts that meet stringent quality requirements.

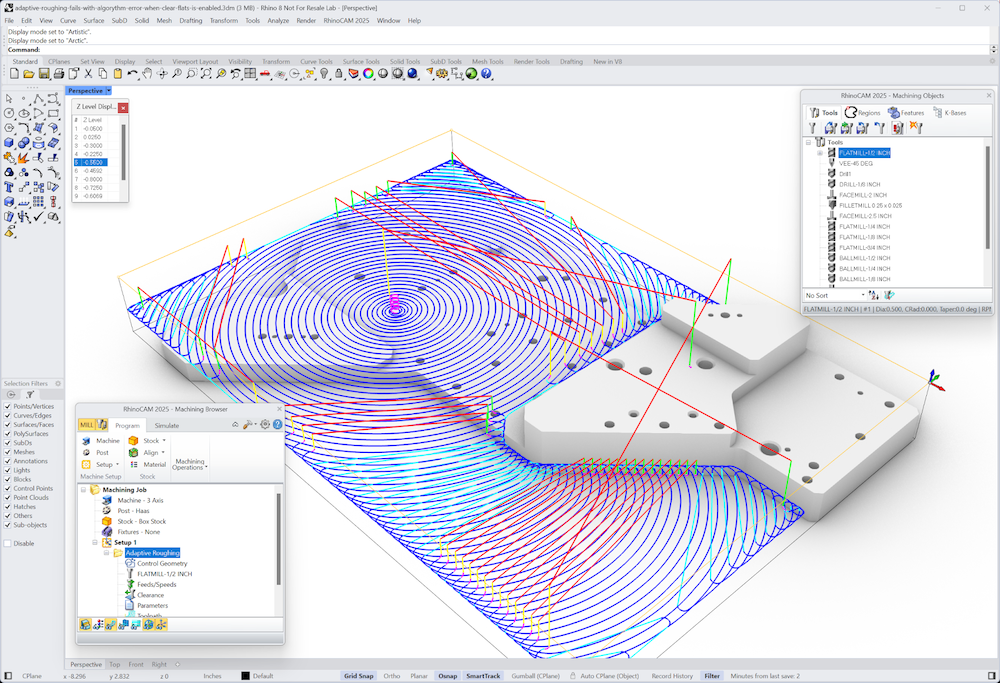

Improved Adaptive Roughing in 3-Axis Machining

Adaptive roughing strategies have been enhanced to provide more efficient material removal in 3-axis machining. The improved algorithms result in faster roughing cycles and reduced tool wear. Users can now take advantage of more aggressive cutting parameters without compromising tool integrity or part quality.

Advancements in 2-Axis Machining

The 2025 versions bring several advancements to 2-axis machining, including: - Thread Milling Enhancements: Improved support for thread milling operations allows for precise threading in various materials, enhancing the versatility of the machining process. - Cutter Compensation Improvements: Enhanced control over cutter compensation ensures that parts are machined to exact specifications, accounting for tool wear and deflection. These improvements contribute to more accurate and efficient 2-axis machining operations, making the software suitable for a wide range of applications.

Enhancements to 5-Axis Curve Machining

5-axis curve machining has seen significant enhancements, providing users with greater control and flexibility when machining complex geometries. The improvements include better toolpath generation algorithms that result in smoother motion and higher-quality surface finishes. These enhancements open up new possibilities for machining intricate parts in industries such as aerospace and automotive.

Rigid Tapping Cycle in Hole Making

The addition of the rigid tapping cycle in hole-making operations allows for precise and efficient threading without the need for specialized tapping heads. This feature synchronizes the spindle rotation with the feed rate, ensuring accurate thread creation and reducing the risk of tap breakage.

Post-Processor Enhancements and Expanded SDK

MecSoft has made numerous post-processor enhancements to support a wider range of CNC machines and controllers. These updates ensure that users can generate accurate G-code tailored to their specific equipment, reducing the need for manual edits and minimizing errors. Additionally, the expanded RhinoCAM Software Development Kit (SDK) offers developers more tools to automate machining processes. This expansion allows for the creation of custom automation scripts and integration with other software solutions, further streamlining workflows.

Maximizing Potential with Compatible Software

To fully leverage the capabilities of RhinoCAM 2025 and VisualCAD/CAM 2025, users can integrate these solutions with other compatible software products available on the NOVEDGE website.

Rhino 3D: The Foundation for Advanced CAM Solutions

For RhinoCAM 2025 users, Rhinoceros 3D is the essential foundation. As a powerful and versatile 3D modeling software, Rhino 3D provides the platform upon which RhinoCAM builds its advanced CAM functionalities. With Rhino 3D's extensive modeling tools and support for a wide array of file formats, users can design complex models ready for precision machining.

xNURBS: Enhancing Surface Modeling with Rhino

To further enhance surface modeling capabilities within Rhino, xNURBS is a valuable plug-in that works exclusively with Rhino. xNURBS utilizes a powerful NURBS technique to create high-quality surfaces with ease. Its intuitive approach allows users to generate complex smooth surfaces that meet aesthetic and engineering requirements, which can then be machined using RhinoCAM 2025.

Luxion KeyShot: Bringing Designs to Life

For users looking to create stunning visualizations of their designs, Luxion KeyShot offers seamless integration with Rhino 3D. KeyShot provides real-time rendering and animation capabilities that help designers and engineers visualize their products with photorealistic detail. By integrating KeyShot into their workflow, users can present their machined parts and assemblies in the most compelling way possible.

The Power of an Extensive Plug-in Ecosystem

Rhino 3D boasts a vast ecosystem of plug-ins that significantly expand its capabilities across various application domains, such as jewelry design, computational fluid dynamics, naval engineering, and architecture. This extensibility allows users to tailor their software environment to specific industry needs and challenges. By leveraging the combined power of these plug-ins with RhinoCAM 2025, users can develop comprehensive solutions that address complex design and manufacturing requirements. This integration underscores the importance of choosing software platforms that support extensibility and customization.

Design Software: Sophistication Meets Affordability

The advancements in design software, as demonstrated by RhinoCAM 2025 and VisualCAD/CAM 2025, reflect a broader trend towards increased sophistication and affordability in the industry. These tools provide powerful features that were once reserved for high-end, expensive systems, making them accessible to a wider range of professionals and businesses. Investing in modern design and manufacturing software leads to significant gains in productivity and return on investment. With features like feed rate optimization, adaptive roughing, and enhanced machining strategies, users can reduce machining times, improve part quality, and streamline operations.

Conclusion

The release of RhinoCAM 2025 and VisualCAD/CAM 2025 marks a significant milestone in CAM software development, offering users enhanced features and capabilities that drive efficiency and precision. By integrating these tools with compatible software like Rhino 3D and xNURBS, professionals can create powerful workflows tailored to their specific needs. For more information about the newest and most advanced design software technology, we encourage you to contact our sales team at NOVEDGE. Our experts are ready to assist you in selecting the right solutions to elevate your design and manufacturing processes.

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …