Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

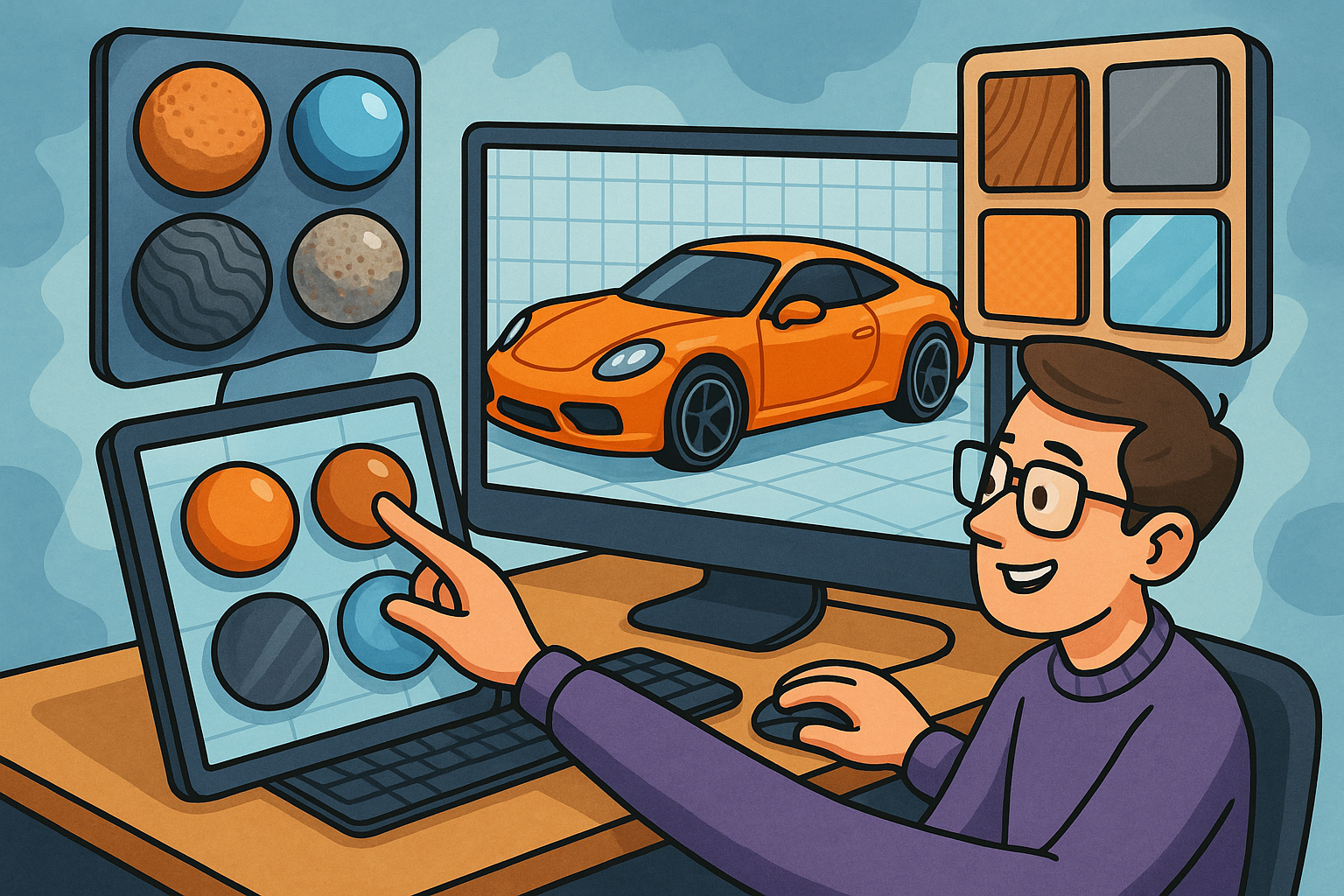

Enhancing Realism in Digital Prototyping with Advanced Material Libraries

September 30, 2025 11 min read

Digital Prototyping: Setting the Stage for Realism

Definition of Digital Prototyping and Its Significance

In today’s ever-evolving design landscape, the process of digital prototyping has emerged as an indispensable tool for professionals striving to bring their visions to life in a virtual space before any physical model is realized. Digital prototyping refers to the creation of detailed, interactive, and highly realistic representations of products using advanced design software. This process enables designers and engineers to visualize, refine, and iterate their concepts quickly, reducing costs and ensuring optimal performance in the final product. Through the integration of complex algorithms and 3D modeling techniques, digital prototyping has become a fulcrum for innovation across multiple industries, including automotive design, consumer electronics, and architectural planning. The approach allows teams to foresee potential issues and make data-driven decisions, fostering a collaborative environment that is both creative and precise. With the convergence of high-fidelity rendering and simulation capabilities, digital prototyping is no longer a static image but a dynamic, interactive experience that mirrors reality. Furthermore, it provides an immersive way for stakeholders and clients to engage with a design, understand intricate details, and evaluate its functional aspects long before it reaches the production stage. As technology advances, the role of digital prototyping continues to expand, integrating new methods of communication, simulation, and material computation.

By leveraging computational power and near real-time simulation, digital prototyping also plays a vital role in reducing development cycles and increasing the overall efficiency of product development. This advanced approach facilitates the evaluation of design alternatives and serves as a medium for conveying complex engineering concepts in an accessible format. The interplay between virtual and physical design spaces has never been more pronounced, with digital prototypes enabling rigorous performance testing under varied conditions and stress scenarios, and thus supporting a more resilient design process. The advent of this technology has permanently altered the design workflow, creating an environment where iterative improvement based on detailed visual and simulation data is paramount. As design teams rely on these digital iterations, the level of detail and realism continues to improve, marking the start of a new era in prototype development.

Integration with Advanced Material Libraries

A significant leap toward achieving realism in digital prototyping is the incorporation of advanced material libraries into design processes. These libraries curate extensive databases of material properties that include precise textures, physical characteristics, reflectivity, transparency, and other details that mirror real-world behaviors. The integration of such material libraries allows designers to simulate how various materials respond to differing environmental conditions such as lighting, temperature, and wear. When incorporated into digital prototyping workflows, these libraries empower designers to select materials that not only look authentic but also behave in a manner consistent with their physical counterparts. This level of detail is particularly critical when producing photorealistic visualizations for client presentations, product showcases, or performance simulations. In professional environments, the interplay between digital designs and realistic materials often makes the difference between a concept that is merely appealing and one that is convincingly lifelike.

The strategic use of advanced material libraries further extends the capabilities of design software, allowing for intuitive integration across multiple platforms. Many leading design software solutions have developed plug-ins or native support to import and manipulate these libraries, enabling seamless transitions between modeling, simulation, and rendering stages. This integration ensures that the material properties remain consistent and accurate throughout the design process, whether the output is a static image or an interactive simulation. Furthermore, the detailed representation of materials provides an essential reference point for iterative design improvements, helping designers fine-tune the interplay between light, texture, and geometry in their virtual prototypes. As a result, projects benefit from an enhanced level of communication with clients and stakeholders who can see and experience subtle design choices before any physical prototype is produced. This iterative and informed design process dramatically reduces the margins for error and streamlines the progression from initial concept to final production.

The Role and Value of Advanced Material Libraries

Technical Aspects of Material Libraries

Advanced material libraries are at the forefront of modern design innovation, offering a comprehensive suite of technical resources that allow digital models to reflect the nuances of real-world materials. These libraries encompass a range of data including high-resolution textures, accurate physical properties, and attributes such as reflectivity, refractive indices, and surface roughness. Designers can manipulate these parameters to simulate the interaction of light and matter in a highly controlled environment. By integrating these capabilities, the libraries enable accurate predictions of how materials will react under various lighting conditions, stresses, or environmental influences. As design software becomes progressively more sophisticated, the need for a realistic portrayal of materials escalates. This is not only critical for visual authenticity but also for functional simulations where the physical behavior of materials under different scenarios must be anticipated. The aggregated technical data contained in these libraries also fosters a more integrated workflow, where designers are empowered to customize and tune material properties in accordance with project-specific requirements.

The interplay between computational design and physical simulation is further enhanced by these libraries, which provide a bridge between the idealized virtual realm and the empirical laws of physics. The detailed data sets allow for predictive modeling of phenomena such as wear and tear, UV aging, and environmental degradation. Such simulations provide valuable insights during the early stages of product development, helping to identify potential points of failure or areas where materials may underperform. This technical foundation fosters a better understanding of material behavior, which feeds back into the design process and encourages more robust model optimizations. By incorporating detailed large-scale material databases, designers and engineers can ensure higher fidelity in their digital representations, thereby enhancing both aesthetic quality and functional accuracy. This technical rigor is indispensable in fields such as aerospace, automotive, and consumer product design where even minor deviations from expected performance can have significant implications.

Enhanced Accuracy in Design and Client Communication

One of the core advantages of using advanced material libraries in digital prototyping is the marked improvement in design accuracy and the quality of client communications. By using these libraries, designers can produce realistic simulations that provide a true-to-life representation of the final product. The fidelity provided by authentic textures and accurate material properties helps create visuals that not only meet but often exceed client expectations. When materials are represented with precision, every aspect from subtle gloss variations to intricate surface imperfections adds to the overall realism of the visual output. This heightened level of realism bridges the gap between conceptual designs and real-world products, making it easier for clients to visualize end results. Consequently, the decision-making process becomes informed and efficient, as design iterations can be seamlessly adjusted in response to client feedback. Moreover, the implementation of these libraries supports clear, data-driven communication among all stakeholders, ensuring that design intentions are faithfully conveyed throughout the project lifecycle.

In addition to reinforcing design accuracy, the realistic portrayal of materials greatly enhances the persuasive power of presentations and product demos. Clients and decision makers gain a more tangible understanding of a product’s key features and quality, fostering trust and reducing uncertainties that often accompany early-stage design concepts. The ability to simulate accurate visual and physical properties through material libraries has effectively transformed digital prototypes into interactive experiences, which in turn narrow the communication gap between design teams and non-technical stakeholders. In effect, the emphasis on material authenticity contributes to a smoother transition from the theoretical design phase to the tangible production phase, ensuring that the final output resonates with both form and function. The convergence of art and science within these libraries supports a holistic approach to design, ingraining a level of meticulous attention to detail that is crucial in competitive markets where the smallest detail can influence product success.

Support for Environmental Simulation and Material Behavior

Advanced material libraries play a pivotal role in simulating environmental conditions and anticipating material behaviors under different scenarios. In an era where sustainability and environmental impact are at the forefront of design considerations, these libraries offer tools to model how materials perform under varying natural conditions. For instance, designers can simulate the effects of prolonged exposure to sunlight, moisture, or temperature fluctuations, thereby predicting degradation, color shifts, or structural impact. This simulation capacity is especially valuable in architectural design and product engineering, where materials need to withstand diverse environmental challenges. By employing accurate material properties and behavior models, design software can emulate the interactions between light, shadow, and texture in a way that mirrors actual physical conditions. This capability is critical for validating design choices in safety-critical applications, ensuring that a digital prototype will translate into a functional and durable real-world product.

Furthermore, these simulation tools extend beyond mere aesthetics. They provide actionable insights into the long-term performance and reliability of materials. This data is crucial, especially in projects where environmental stresses can result in significant wear or potential failure over time. With the support of advanced material libraries, digital prototyping evolves into a predictive tool that optimizes material selection, informs maintenance schedules, and improves overall design robustness. The comprehensive data sets available in these libraries form the backbone of sophisticated simulation algorithms, enabling real-time adjustments and iterative improvements during the design process. Consequently, designers have the ability to foresee and mitigate environmental risks well before production begins, ensuring that the end product not only meets aesthetic standards but also excels in performance and durability.

Implementation, Integration, and Future Trends

Best Practices for Integrating Advanced Material Libraries

Seamless integration of advanced material libraries into existing design workflows requires a strategic approach that balances technical, aesthetic, and practical considerations. Leading design software platforms now offer inbuilt support or extensible plug-ins to import these material libraries, ensuring that the data is non-disruptively merged into existing models and simulation environments. Key practices involve the careful analysis of the library’s compatibility with current tools, verifying that the material properties are accurately translated within the modeling software. In addition, it is essential to adopt standardized workflows that enable teams to update material data in real-time. This augmentation of the digital prototyping process not only raises the fidelity of design outputs but also enhances the overall communication of a project’s visionary aspects to clients and investors. The incorporation of these resources into daily practices demands a thorough understanding of the technical specifications of both the software and the material library content. By establishing a rigorous check on version control and data integrity, design professionals can ensure that every iteration remains true to the intended material properties and that any simulation of physical stress or lighting is based on real-world principles.

To further clarify the integration process, consider the following best practices:

- Compatibility with existing design tools: Ensure that the material library format and parameters seamlessly integrate with your current software suite, reducing the need for extensive conversion or data manipulation.

- Scalability and customization features: Select libraries that allow for easy updates, modifications, and the addition of new materials as project needs evolve.

- Real-time rendering capabilities and performance considerations: Leverage tools that facilitate quick visualization and simulation to maintain productivity and meet deadlines.

Adhering to these practices not only optimizes digital prototyping workflows but also builds a robust foundation for future design enhancements. This approach allows teams to focus on creating innovative products while ensuring that the underlying material data remains both accurate and adaptable.

Emerging Trends and Future Directions

Looking ahead, the field of digital prototyping is set to be transformed by emerging trends that leverage the power of artificial intelligence and cross-platform integration. One significant trend is the incorporation of AI-driven material recommendations where algorithms analyze historical design data, project parameters, and client preferences to suggest the most optimal materials from the library. This not only expedites the design process but also ensures a more data-informed selection of materials, thereby enhancing the final output’s realism and performance. Additionally, the ongoing expansion of material databases, enriched with both empirical testing data and real-world performance metrics, is poised to set new standards in material simulation. The innovative use of these vast repositories is enabling a dynamic interplay between computational analysis and material science, allowing for predictive modeling of durability, functionality, and environmental resilience.

Moreover, improvements in cross-platform interoperability are making the integration of material libraries more fluid across diverse design environments. As software solutions become increasingly modular, designers can expect smoother transitions between initial concept modeling, detailed simulation, and high-quality rendering. Enhanced real-time rendering capabilities facilitate immediate feedback and iterative improvements that were once time-consuming or cost-prohibitive. Coupled with these technological advancements, the development of industry standards for material data exchange is fostering a more unified ecosystem. This standardization not only aids in reducing discrepancies between simulation and reality but also allows for broader collaboration among specialists from different fields. Overall, these emerging trends emphasize the importance of staying abreast of technology innovations and continuously adapting workflows to harness the full potential of advanced material libraries in creating products that are both visually impeccable and structurally sound.

Integrative Strategies for Cross-Platform Interoperability

As digital prototyping continues to grow at a rapid pace, ensuring robust cross-platform interoperability has become a top priority for design teams worldwide. Integrative strategies now emphasize connectivity among various design tools and simulation software to provide a cohesive workflow across multiple stages of development. This holistic approach not only maximizes the utility of advanced material libraries but also allows for synchronized updates across different modules—be it for modeling, rendering, or performance simulation. Designers are increasingly focusing on creating a seamless exchange of data that maintains the fidelity of material properties, regardless of the tool used. This requires not only technical compatibility but also a shift towards adopting standard protocols and file formats that are universally recognized. In such integrated environments, complex projects become more manageable as design iterations, material updates, and simulation recalibrations occur automatically, reducing both the time and potential for error in the workflow.

Effective strategies for achieving this interoperability include the establishment of centralized material management systems that serve as the single source of truth for material attributes. These systems are designed to communicate with various proprietary CAD and simulation platforms through open APIs and standard data formats such as XML or JSON. As a result, design teams can synchronize their creative processes and ensure consistent material behavior across every digital prototype iteration. Furthermore, regular updates and collaborative feedback loops are vital in refining these integrative strategies. They allow for the rapid identification and resolution of discrepancies between different software environments, ensuring that the overall design fidelity remains uncompromised. By investing in robust interoperability frameworks, organizations position themselves to benefit significantly from emerging technologies and maintain a competitive edge in a market that increasingly demands rapid innovation and uncompromised quality.

Conclusion

Recap of the Importance of Realism in Digital Prototyping

In summary, the evolution of digital prototyping anchored by advanced material libraries has redefined the design process across numerous industries. The integration of photorealistic textures, precise physical properties, and dynamic environmental simulations has provided designers and engineers with an unprecedented level of control and insight. This enhanced realism not only elevates the aesthetic value of digital prototypes but also imbues them with functional fidelity, which is essential when transitioning from a digital concept to a tangible product. The ability to predict material behaviors under real-world conditions—ranging from light reflection and texture detail to durability under stress and environmental wear—has fundamentally altered the speed and accuracy of iterative design cycles. In this context, digital prototyping emerges as a holistic methodology that addresses both creative expression and practical engineering challenges. By harnessing these advanced simulation tools, professionals are better equipped to communicate design intents, manage client expectations, and ultimately deliver products that resonate with high standards of performance and visual appeal.

Furthermore, the drive toward realistic digital prototypes represents an evolving synthesis of art and science. It underscores the significance of data-driven design that not only anticipates market needs but also leverages technological advancements to stay ahead of emerging trends. As designers continue to refine their workflows and adopt innovative integrations, the overall quality and efficiency of the development process are bound to improve. Taking full advantage of these sophisticated tools means embracing a future where the boundaries between digital and physical realities continue to blur, creating a landscape where creativity, precision, and functionality are seamlessly integrated.

Encouragement towards Innovation and Future Adoption

Looking to the future, the emphasis on pushing the boundaries of realism in digital prototyping remains a critical element for growth and innovation in design. The continuous integration of next-generation features such as AI-enhanced material recommendations, expanded material databases, and cross-platform interoperability will drive the industry towards more streamlined, efficient, and accurate design processes. As professionals seek to elevate their work and provide richer, more engaging client experiences, adopting these advanced material libraries will play a central role in achieving such goals. Moreover, fostering a culture of perpetual improvement and staying abreast of emerging technological developments is imperative for maintaining competitive advantage. The commitment to innovation not only enhances the aesthetic and functional quality of developed products but also paves the way for breakthrough advancements in how we visualize, simulate, and interact with digital designs.

In an era where rapid prototyping and iterative feedback cycles are vital, embracing these sophisticated simulation tools translates into tangible benefits. By embedding realism into every facet of the design process—from initial sketches to final renderings—professionals can ensure that their deliverables resonate with both technical precision and artistic flair. The future of digital prototyping demands that industry players continuously challenge the norm and explore novel approaches to material simulation and integration. As the design community collectively embarks on this journey of innovation, the lessons learned and the tools developed will set new benchmarks for quality and performance in the realm of digital creation.

Also in Design News

Design Software History: Handbooks to Hyperscale: The Evolution of Materials Data, PLM and the Digital Thread

February 05, 2026 12 min read

Read More

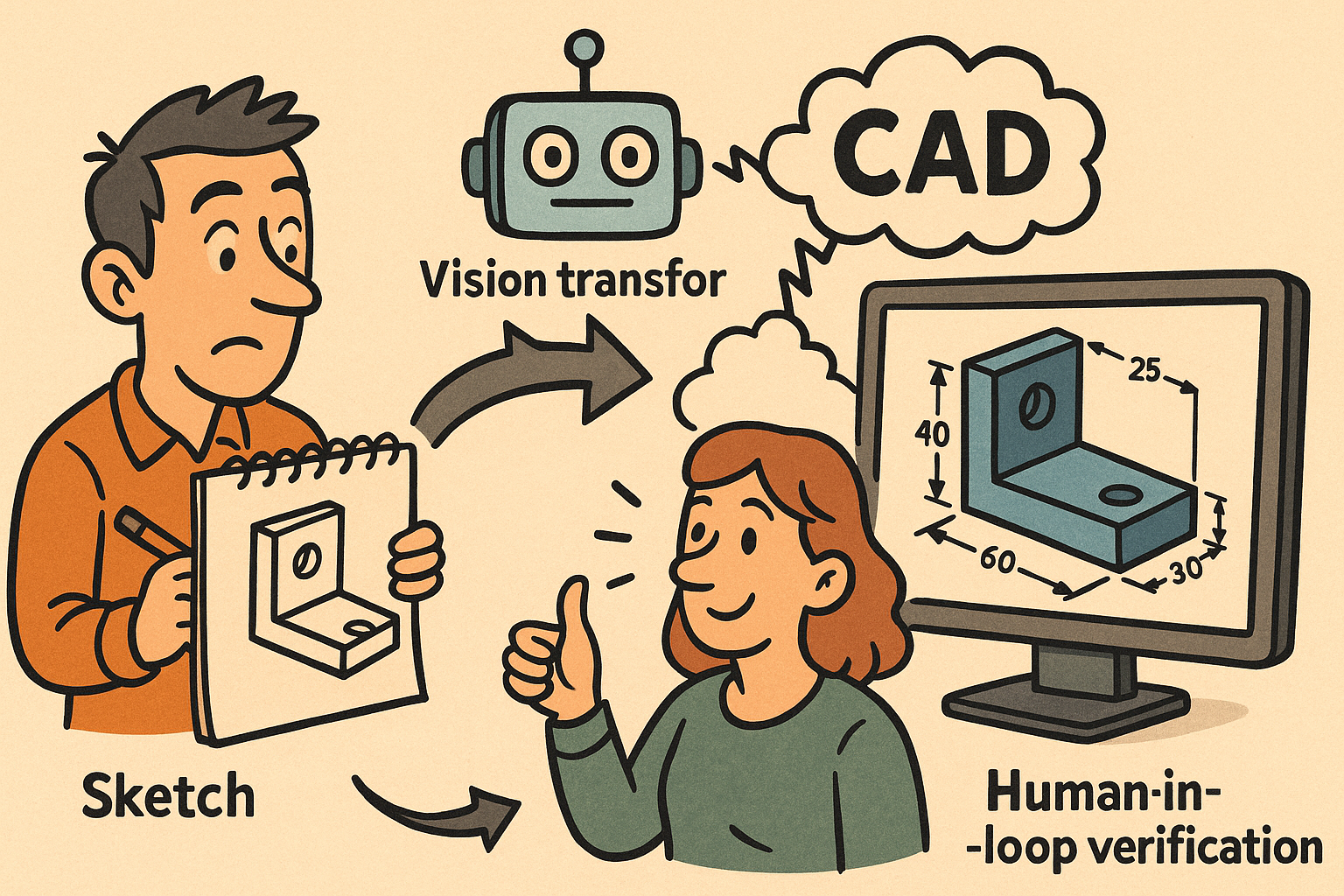

Sketch-to-CAD: Preserving Parametric Design Intent with Vision Transformers, LLM-Orchestrated CAD DSLs, and Human-in-the-Loop Verification

February 05, 2026 10 min read

Read More

Cinema 4D Tip: Scene‑Referred Color Grading Workflow with ACES and 32‑bit EXR

February 05, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …