Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Origins of Design Software in Medical Devices: Regulatory Pressures and the Shift from 2D Drafting to Advanced 3D Modeling and Simulation

August 26, 2025 9 min read

Origins and Early Foundations: Regulatory Pressures and Early CAD Adaptations

The origins of design software in the medical device industry can be traced to a period when regulatory pressures and the escalating need for improved patient safety created a rigorous environment for innovation. Initially, the sector was driven by the necessity to comply with stringent safety standards and to meet the demands of various regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). The early 1970s and 1980s witnessed a tremendous surge in the complexity of biomedical devices which, in turn, pushed developers to adopt computational methods to ensure that design integrity could be maintained throughout production cycles. During this period, the reliance on traditional hand-drawn drafting was rapidly becoming obsolete, and computer-aided design (CAD) systems emerged as a viable alternative. These early software systems were initially developed to serve broad engineering purposes but were eventually adapted to suit the specialized needs of biomedical applications. The challenge was multifaceted: designers had to contend with limited computational power, rudimentary user interfaces, and a stark lack of integrated simulation functionalities. Pioneering engineers and software developers, often working within the constraints imposed by early hardware limitations, began to incorporate novel algorithms to increase precision, despite the obstacles presented by early hardware architectures.

Regulatory Demands and Early Software Constraints

One of the primary drivers behind the adoption of design software was the pressing need to conform to emerging industry standards that ensured device safety and effectiveness. Regulatory agencies demanded robust design validation strategies, steering manufacturers away from traditional drafting techniques. In response, early CAD systems began emphasizing features that could accommodate detailed geometric models and simulate physical interactions among different components. Despite their groundbreaking nature, these tools faced challenges that included low computational speed, minimal graphical output capabilities, and a significant gap between the level of detail required by biomedical designs versus what the software could currently offer. Users of these early systems had to adapt to interfaces that were often non-intuitive and had limited functionality, leading to a steep learning curve and increased reliance on manual corrections. Developers had to design their programs to work within tight memory constraints while also ensuring that processes such as dimensioning, scaling, and tolerancing were accurate enough for the demanding regulatory environment. Consequently, early software innovations often involved creative workarounds like modular interfaces and plug-in modules that incrementally improved upon core functions.

Early Adaptations for Complex Biomedical Applications

The adaptation of early CAD technologies to biomedical applications was nothing short of revolutionary. Engineers and designers in the medical field recognized that the integration of computational analysis could dramatically reduce errors and enhance the safety profiles of devices. At a time when processors barely measured up to present-day benchmarks and graphical displays were in their infancy, early software engineers crafted tailored applications to simulate physiological interactions and predict mechanical failures. The initial emphasis on detailed documentation and design traceability helped bridge the gap between creative ideation and technical feasibility. As a result, the push to incorporate computing into design processes laid the foundation for what would evolve into a robust system of computer-aided engineering (CAE) tools. This cross-disciplinary approach not only improved patient outcomes by reducing the risk of device failure but also spurred the evolution of industry standards that continue to influence biomedical design today. The challenges of the early era—characterized by rudimentary interfaces and limited process automation—catalyzed an era of technological experimentation that balanced the limitations of early computing power with the insatiable demand for more precise and reliable biomedical devices.

Evolution of Design Processes and Technology: From 2D Drafting to 3D Modeling

The evolution of design processes in the medical device industry is marked by a transformative shift from traditional 2D drafting to complex 3D modeling and simulation. During the initial decades of CAD adoption, most computer-aided systems were limited in their output, primarily offering flat, two-dimensional representations of devices. However, as computational capability advanced in line with Moore’s Law, engineers and designers began to harness the power of 3D modeling to achieve more realistic, interactive visualizations. The driving forces behind this transition included not only advances in hardware and software architectures but also a deeper understanding of the functional requirements dictated by biomedical applications. The integration of finite element analysis (FEA) in the design process introduced sophisticated simulation techniques that allowed for stress testing and fatigue analysis of medical devices before physical prototypes were even built. This integration helped optimize designs by enabling iterative testing and refinement that closely mirrored real-world performance. The advent of parametric and solid modeling further revolutionized workflows by introducing the capacity to link designs with robust mathematical models, thereby enabling modifications that cascaded through the digital model in real time without the need for complete redesigns.

Transition from 2D to 3D: Enhancing Visualization and Simulation

The move from 2D drafting to 3D modeling marked a paradigm shift in how medical devices were conceptualized, designed, and validated. Early 2D techniques, while useful for simple schematics, could not accurately capture the intricate geometries of implants, prosthetics, and diagnostic instruments. The development of 3D CAD software introduced an accurate spatial representation, enhancing the designers’ ability to visualize potential issues such as interference and misalignment. The use of bullet lists by developers to outline system requirements was fundamental in ensuring that critical features were not overlooked during digital prototyping:

- Accurate geometric representation: Ensuring the digital model captured every detail crucial to device performance.

- Enhanced simulation: Integrated FEA allowed for better predictive modeling of mechanical stresses and fatigue over time.

- Parametric design features: Enabled real-time adjustments that propagated through the entire model seamlessly.

Integration of Computational Algorithms and FEA

Integral to the evolution of design processes was the infusion of advanced computational algorithms. These algorithms allowed for deeper analysis and optimization of device performance. Finite element analysis emerged as a critical tool, offering engineers the means to simulate dynamic behaviors under various physical conditions. This enabled the precise calculation of material stress, strain distribution, and potential points of failure—a crucial factor in ensuring the longevity and reliability of medical devices. The birth of specialized software solutions that combined traditional CAD with FEA provided a synergistic platform to conduct simulations that mimicked real-life scenarios. Among the groundbreaking innovations was the development of parametric modeling systems, which allowed designers to define complex relationships between different geometric features. This parametric approach significantly reduced the cumbersome processes of manual redrafting subsequent to every design revision. Over time, what started as a rudimentary integration of computation evolved into a robust, holistic design ecosystem where digital experimentation could lead to rapid iteration, validation, and refinement of device concepts. The evolution of these design processes not only streamlined workflows but also contributed to the overall reliability and safety of medical devices, a testament to the collaborative efforts of engineers, software developers, and regulatory experts.

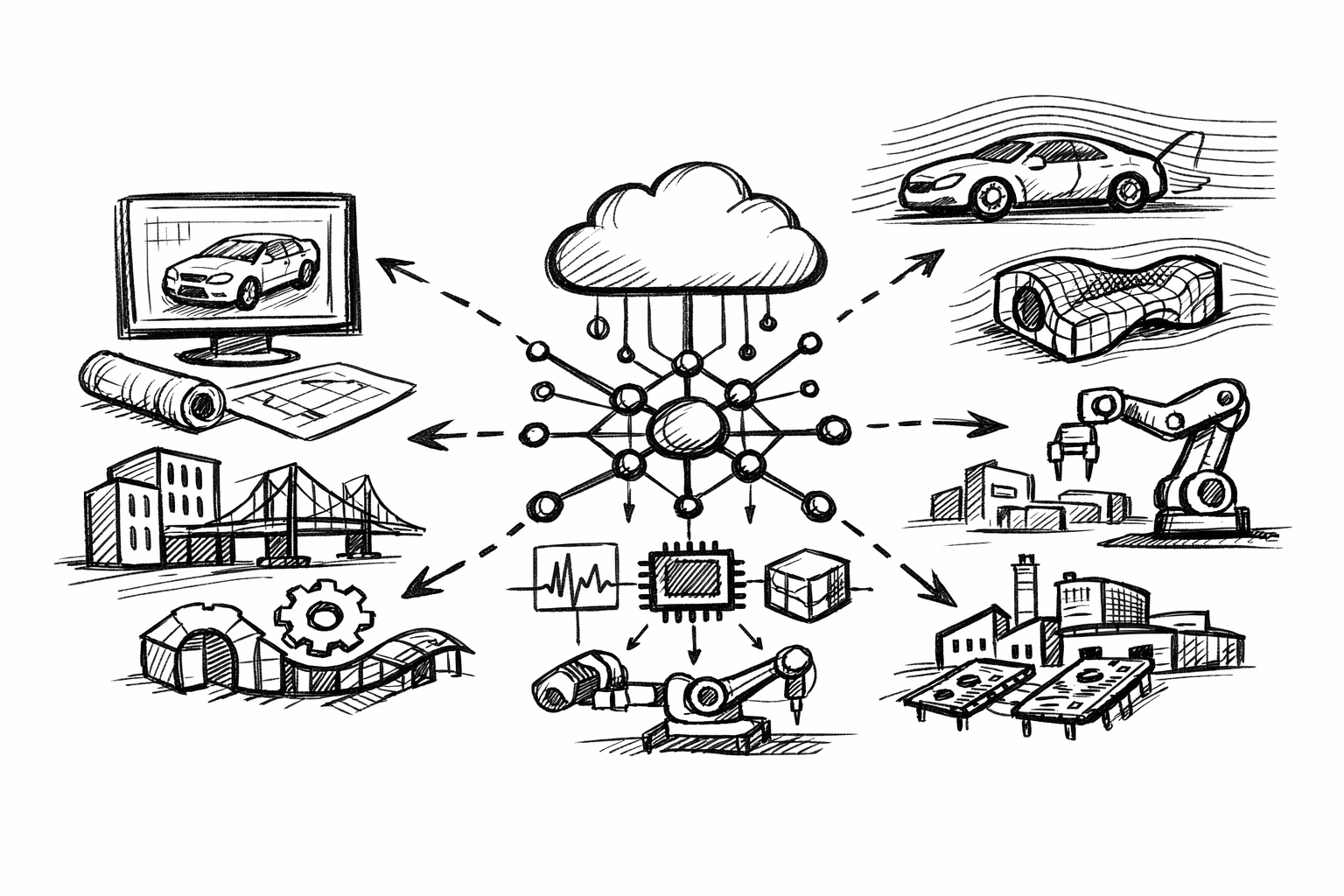

Influential Innovations, Pioneers, and Industry Collaborations: Shaping the Future of Medical Device Design

The journey of design software innovation in the medical device realm owes much to the trailblazing contributions of various companies and visionaries. In the late 20th century, established CAD vendors such as AutoDesk and Dassault Systèmes began adapting their products to meet the unique needs of the biomedical industry. Alongside these industry giants, numerous niche startups emerged, dedicated exclusively to developing specialized software solutions for medical applications. These efforts were characterized by a spirit of innovation and a commitment to overcoming the technical limitations of early CAD systems. The need for real-time simulations, high-fidelity renderings, and comprehensive design validations spurred collaborative efforts between software engineers, biomedical researchers, and regulatory experts. Such collaborations led to groundbreaking breakthroughs in areas including parametric modeling, advanced finite element analysis, and real-time multi-physics simulations. Moreover, the integration of these software capabilities contributed not only to device safety but also to improved design cycles that significantly reduced time-to-market for vital medical devices.

Key Innovators and the Role of Pioneering Companies

Several key players in the industry have been instrumental in shaping the evolution of design software. Companies such as Siemens Digital Industries Software, PTC, and Bentley Systems played pivotal roles by developing robust platforms that supported a wide array of design activities required by the medical field. These companies implemented software architectures that allowed for bullet list style planning and agile responses to emerging regulatory needs. Their systems supported the critical transition from 2D to 3D modeling, provided integration with simulation tools such as FEA, and even explored incorporating early iterations of computer-aided manufacturing (CAM) technologies. The contributions of these organizations were complemented by individuals who underscored the importance of interdisciplinary collaboration. Renowned innovators in the field recognized that bridging the gap between design and regulatory compliance was essential. This led them to pioneer methodologies that are now considered industry standards, thus laying down a framework that continues to guide software developments. Their work was characterized by rigorous testing, iterative feedback loops, and an unwavering commitment to patient safety, all of which collectively pushed the boundaries of what was considered technologically possible in the design of medical devices.

Collaborative Efforts Between Regulatory Bodies and Software Developers

A critical factor in the success of these innovations was the close cooperation between software developers and regulatory bodies. Regular consultations with agencies such as the FDA ensured that design software not only met technical specifications but also conformed to evolving safety standards. This collaboration fostered an environment where continuous feedback led to incremental improvements in system capabilities. Additionally, industry consortia began sharing best practices that emphasized the importance of simulation in reducing design risk factors. This collaborative spirit propelled the integration of automated error-checking routines and the establishment of rigorous validation protocols that became cornerstones of modern design software. The spotlight on regulatory compliance was further intensified by the increasing complexity of medical products, which demanded greater precision and reliability from digital models. By harnessing the collective insights of engineers, testers, and regulatory experts through structured workshops and technical symposia, the industry managed to evolve design software from a rudimentary drafting tool into a comprehensive, dynamic solution capable of supporting sophisticated design, simulation, and validation processes. This transformative period laid the groundwork for future initiatives aimed at enhancing patient safety and optimizing device performance through continuous software innovation.

Conclusion: Historical Trajectory and Future Implications for Design Software

The evolution of design software in the medical device industry stands as a testament to the relentless pursuit of innovation and safety in technology-driven product development. As outlined in this discussion, the journey began in an era defined by limited computational resources and rudimentary software interfaces, evolving into a sophisticated ecosystem where dynamic 3D modeling, finite element analysis, and parametric design have become integral to the design process. This historical trajectory underscores the significant role played by collaborative efforts between regulatory bodies, engineers, and pioneering software developers. The early challenges—ranging from coping with limited computing power and primitive visualization techniques to dealing with the rigorous demands of safety standards—spurred the development of essential industry tools and methodologies that continue to evolve today. The evolution from basic CAD systems to state-of-the-art simulation platforms has not only transformed design workflows but has also fundamentally reshaped the strategies for ensuring device safety and performance. By incorporating advanced algorithms, setting standards for precision, and fostering a cooperative environment across industries, the medical device sector has continuously pushed the boundaries of design technology to new heights.

Reflecting on the Past to Inspire Future Innovations

In reflecting on this historical evolution, it becomes clear that the experiences of early software adoption have provided invaluable lessons for current and future technological advancements. The painstaking efforts to overcome hardware limitations and interface challenges have informed modern development practices that emphasize scalability, interoperability, and continuous improvement. Today’s design software solutions are built on decades of cumulative expertise, integrating powerful simulation engines, real-time data analysis, and precision modeling to create safer and more effective medical devices. The legacy of early pioneers, who often worked with highly constrained resources yet delivered groundbreaking solutions, serves as a beacon to current innovators striving for the next significant breakthrough. This enduring spirit of collaboration and adaptation continues to inspire ongoing research and development, ensuring that as technology evolves, the foundations of safety, accuracy, and patient well-being remain at the forefront of design philosophy.

Key Takeaways and the Path Forward

As the medical device industry looks to the future, it is crucial to appreciate the milestones that have collectively shaped modern design software. The evolution from 2D drafting to sophisticated 3D modeling and simulation has not only reduced the risks associated with device failure but has also accelerated innovation cycles. Key takeaways include the importance of integrating computational algorithms with traditional design processes, the critical value of cross-disciplinary collaboration, and the resilience of early innovations that have paved the way for today's technology. Looking ahead, there is a growing recognition that future challenges—such as increasing design complexity, regulatory pressures, and the need for ultra-precise simulations—will require further strides in software development. The lessons learned from the interplay of technical ingenuity and regulatory compliance during the early phases of design software evolution should continue to guide industry efforts. Emphasizing a balance of collaboration, innovation, and cautious risk management will remain essential as the field advances. As medical devices become ever more complex and patient-centric, the transformative history of design software offers not only insights into what has been achieved but also a clear roadmap for what can be accomplished in the future.

Also in Design News

Rhino 3D Tip: Create Consistent, Print-Ready Sheets in Rhino Layouts

March 06, 2026 2 min read

Read More

Beyond CAD Files: Unified Design Graphs for Simulation-Driven, Manufacturable Digital Threads

March 06, 2026 11 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …