Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Why the transition from 2D to 3D is taking forever

December 12, 2006 4 min read

For as long as I can remember, sophisticated 3D CAD systems have been on the verge of fully replacing the supposedly inefficient 2D CAD systems. For years it has been considered just a matter of time before the obvious advantages of 3D systems would push traditional 2D systems out of the market, all with great advantages for designers, companies, and users.

years have passed and 2D CAD systems are still around

Years have passed and 2D CAD systems are still around. We are now approaching the year 2007 and one of the most successful CAD systems is AutoCAD LT, a popular 2D system. If the 3D is so great, why all those people are still using a 2D CAD system?

In order to find an answer, let's ignore the few design contexts intrinsically 2D, where the benefits of 3D are not so obvious. Let's also exclude from our discussion those users that are too rigid or conservative to switch to a new technology, regardless of the advantages. We still left with huge number of 2D users.

Today the cost of a state-of-the-art 3D parametric, feature-based CAD system is comparable with the cost of AutoCAD LT. What's keep those designers and their companies from switching to a 3D?

In order to explain my opinion I'll need an example.

Let's assume we need to design a simple L-bracket part. We can draw a couple of orthogonal views with a 2D system, add a bunch of dimensions and notes, and it's done. Similarly, with a 3D system, we can create a simple profile and extrude it to generate a 3D shape. So at this stage, there is no significant difference between 2D and 3D systems. The advantages of the 3D solution will become evident only if and when we reuse the 3D model in the following phases of the design and manufacturing process, such as when will have to go back to our computer to change the size or shape of our L-bracket. Designers know it very well: it's just a matter of time, someone will always want a change.

For the purpose of this example let's assume we are not a very skilled CAD user, or we are just thinking about our next vacation. Because of that, our sequence of commands to generate the CAD model of the L-bracket would be not optimal. If our system is a 2D system, nobody will ever know how we completed the design. A 2D model is just a collection of simple geometric entities and some text. As long as the drawing makes sense, it doesn't matter how we got it.

Based on our hypothetical limited skills, if we were using a 3D system instead of a 2D, the situation would have been completely different. On one side of the screen the "history tree" will reveal to everybody all our mistakes. Our (supposedly) poor skill would become evident the same moment we need to go back to our 3D model and change some dimension or add new features and details.

a poorly modeled 3D model is virtually unmodifiable

In every 3D CAD system, parametric models created by a "well designed" sequences of operations can support a wide range of dimensional modifications with predictable and consistent results. A well-crafted 3D model can become the archetype for a large group of products. The opposite is also true: a poorly modeled 3D model is virtually unmodifiable. Every tentative to change a critical dimension or to add more details will cause the failure of the model regeneration.

Most of the parts designed every day by CAD users are by far more complex than a simple L-bracket. The higher the complexity of the part, the more critical is the 3D modeling sequence of commands, and more challenging is the task for a 3D CAD operator.

With a 2D CAD system the situation is different. The design process can be even more difficult, because it must be done without the support of a 3D model, but the modeling phase (2D drafting, in this case) is a lot simpler than the corresponding 3D modeling phase. The effort to create a 2D model grows (approximately) linearly with the complexity of the part we intend to design, while the effort to create a 3D model grows with the square of the part complexity and size.

When we look at the big picture of the design and manufacturing process, the initial investment in building a 3D model will pay off with huge interest. (For more on the benefits of transitioning to a 3D system, check out the recent Cadalyst article.) A 2D solution can easily perceived as optimal only if you limit your analysis to the design phase. Transforming ideas into products is a long and complex process, and creating a 2D or 3D model is just one of the first steps.

I welcome your comments on this matter.

Franco Folini

Post Scriptum: You can find a continuation of this discussion on my more recent post: Frederick W. Taylor and 3D Technology.

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

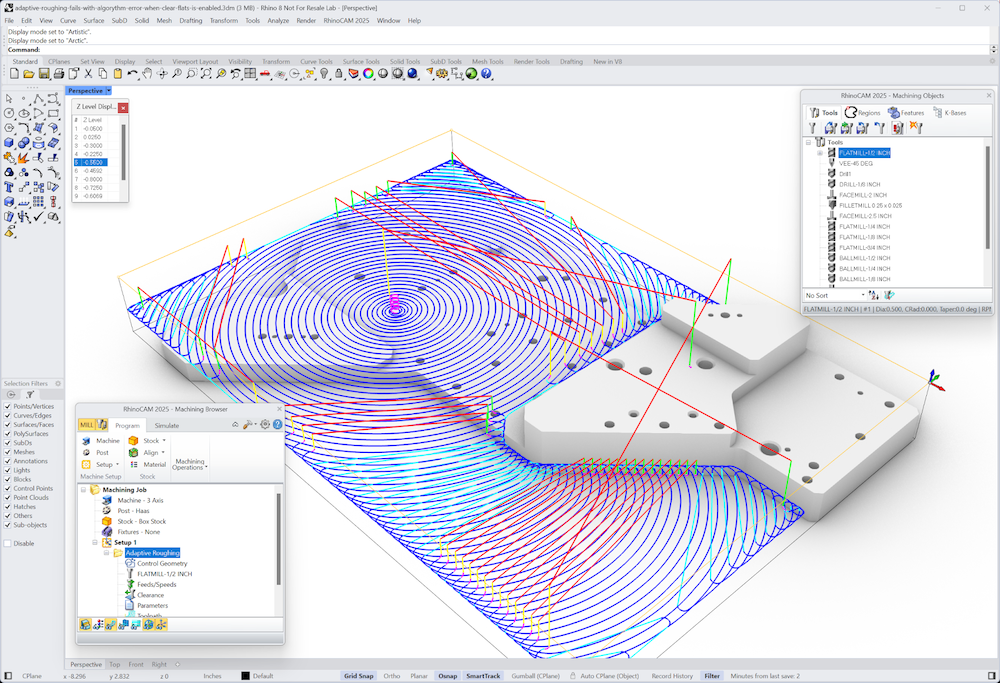

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …