Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Why Direct/Parametric Modeling Hybrid is an Oxymoron

May 01, 2008 2 min read

Parametric CAD systems are based on a complex internal data-structure that represents each geometrical and dimensional constraint as a relationship among two or more entities. When the end-user requests a change to a parameter (dimension), the CAD system propagates the modification to the entire 3D model (it’s called model evaluation) following those relationships while preserving the validity of each single constraint.

In the data structure of a direct-modeling CAD system there are no constraints. They are created on the fly as a way to support high-level modification of the 3D model. For example, if the CAD system sees a tangency between a planar face and a cylindrical face it likely will assume that it’s a constraint and that it should be preserved to guarantee that the behavior of the system follows the original design intent.

The power and beauty of the direct-modeling approach is that in different moments the set of active constraints can change radically. Constraints “captured” to support modification "A" can even contradict constraints “captured” during modification “B”. This is great because gives the end-user incredible flexibility and power.

On the other hand, in a parametric CAD system the set of constraints can be changed only with tedious and complex operations. The benefit of this more rigid approach is that your CAD system knows all the constraints and doesn’t have to guess them. This makes parametric CAD systems more predictable and reliables. If the 3D parametric model was carefully created by a skilled CAD user this can be a huge advantage.

Because of the intrinsic difference between the two approaches, there cannot be a hybrid CAD system where I can create a parametric part, change it using some of the flexible tools offered by a direct-modeling system, and still have a fully parametric part. A direct-editing modification to a parametric model is possible, but it becomes a non-return point — the data structure that supports the parametric nature of the model will not survive.

The recent marketing brochures and blogs that are describing a possible future of CAD based on the hybrid approach make me smile. But we all know that marketing knows no limitations…

Franco Folini

Also in NOVEDGE Blog

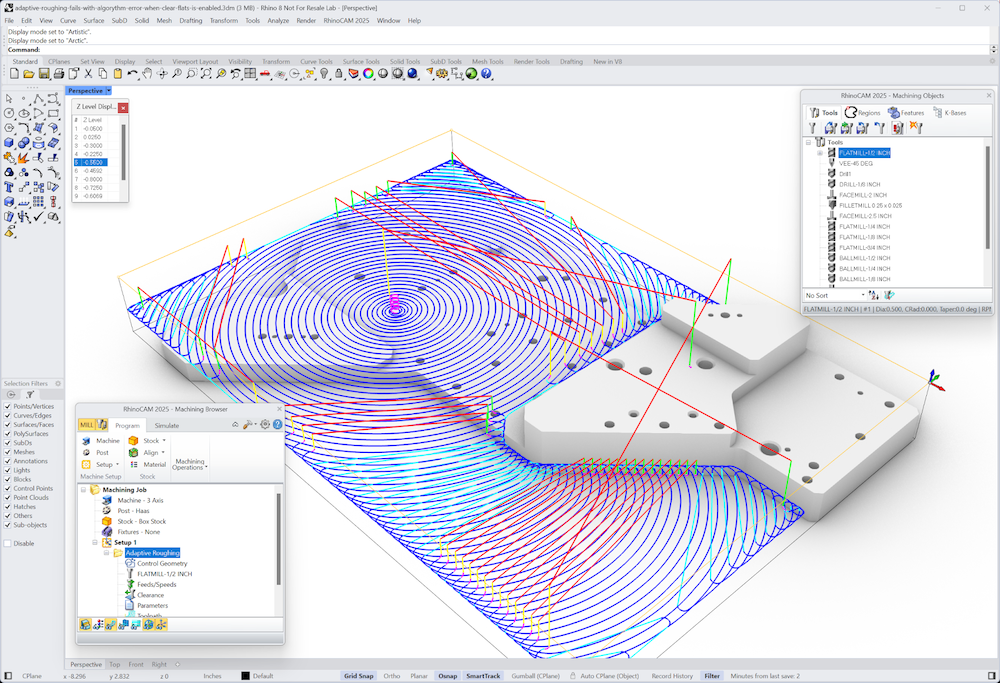

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read More

Maximize Your Architectural Workflow with VisualARQ 3's New Guides Feature

January 30, 2025 5 min read

Read More

Introducing V-Ray 7: Transforming Creative Workflows in Maya and Houdini

January 28, 2025 7 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …