Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Interview with Paul Brown, NX Marketing Director

October 10, 2008 8 min read

Siemens NX, with various names and affiliations, has been around for several years. Nobody would really expect a well establish CAD system to become the lead innovator of a new technology. Usually those kinds of CAD systems invest in maintaining their user base rather than trying to acquire new users and push technological limits. For these reasons I was quite surprised when I read that the new Synchronous Technology, developed by UGS first and then by Siemens, was being deployed not only on the younger Solid Edge but also on the more complex and older UG NX. These radical changes are happening not too long after the acquisition of UGS by Siemens (May 7, 2007). To learn more about this important transition and the implication it is having for all NX users, I asked Paul Brown for an interview.

Paul, can you tell us a bit about yourself and your company?

My company, Siemens PLM Software, is a business unit of Siemens Industry Automation Division and a leading global provider of PLM software and services We have 51,000 customers worldwide with 5.5 million licensed seats of software out there. I am senior director of NX Marketing worldwide. So I head up the marketing for the NX CAD product line.

we have 51,000 customers worldwide with 5.5 million licensed seats

I have been with our company more than 20 years, serving in various roles including technical support and marketing. I have a background in engineering and computer science. I got started in product design at a machinery company. One of my key roles is to work with customers and our development organization to look at how NX can meet the challenges that users face in their day-to-day work.

What impact has the acquisition of UGS by Siemens had on NX evolution?

We continue to lead the PLM market in R&D investment and we remain steadfast in our commitment to our digital product development software suite of products that help our customers develop innovative products faster and more cost-efficiently.

Siemens was impressed with [synchronous technology] enough to help accelerate the development project

One example of this was seen with our launch of synchronous technology. We disclosed the technology during the due diligence process and Siemens was impressed with it enough to help accelerate the development project. We believe the technology is a major breakthrough that is sustainable in the market for years. NX 6 features synchronous modeling in our “Design Freedom” tools.

NX has ambitions to set a new standard for usability in the CAD world. Can you explain how the NX approach is different from other CAD systems?

Traditionally, the approach is to remove functions in order to de-clutter an interface for enhanced usability. I think the main problem with this is it assumes usability is all about two things…can I find the command I want to use and does it work in a way I would expect it to? And that’s fine for new users, but the problem is that usability is more than just those two things it does include those, but as my skills improve I then start looking for more efficiency in the way I have to use the system. So just removing functions can leave you with a system that runs out of power when I get to more complex problems.

users have the ability to access more of the system as they become more efficient

So with NX we wanted to challenge that approach with a new interface that delivers usability without losing functionality. Our users kept telling us that they wanted something that was easier to use, but they didn’t want to lose functionality, so with that as a challenge we had to find a way to get new levels of usability without causing those existing users problems. So we did this by focusing on the workflows our customers had and working to make sure that as a user gets more experienced he can still be productive.We put a significant amount of effort into analyzing how CAD programs are used in a user’s day-to-day workflow. We leveraged an external firm to advise us on how workflows were done in NX vs. competing programs. And we focused interface changes to areas that could make the biggest impact to usability and productivity.

So that’s what lead us to the role-based interface you see in NX today. It means that users have the ability to access more of the system as they become more efficient.

We first introduced the roles-based interface in NX 5 to allow companies to decide exactly what they need in NX. For example, a company can choose to remove a command they never use in their design process, such as performing an extrude to add taper at the same time. We also looked at a number of standard workflows and built pre-packaged roles based around industries. I think that’s important because when somebody installs NX they get a starting point that they are familiar with and can work from. If we had simply said, you can do what you like and offered no guidance as to what you can do the effort we put in probably would not have had the same effect.

NX 5 really helps people get started into NX, but one thing we kept hearing from customers was that they wanted to be able to use more of the screen space. “Why do I want a tree like navigator down the side of my screen and dialogs taking up space? If I’m designing a product I want to see the product! ”That’s a fair question. With NX 6 we built on the foundations we made in NX 5 and added new tools that allow users to remain productive as they become more advanced. So we added a full screen mode which we combined with customizable pop-up toolbars so you can get maximum size of graphics, as big as the monitor you purchase and have all of the commands you want to use used commands right under your cursor. It’s also made even better by technology we’re calling Trueshade which brings advanced visualization capabilities to every user, it has pre-packaged lighting and environments so you can work full screen with shadows, mirroring, material properties. When we review versions with existing customers this is one thing they all like trying out.

This focus on ongoing productivity, allowing the user to control what they really need, makes NX both easy to begin using and highly efficient for the skilled user.

Why in your opinion is direct-modeling reappearing only now after being dismissed by many for several years as an ineffective technology?

I think that there are a number of technology advances that have made it more effective. The fact was the historical approach to direct modeling had mathematical restrictions which limited the types of changes that could be performed. Topology changes were either difficult or simply not allowed. Given that restriction the amount you could change was limited.

Another factor was that it required a lot of very specific user input to identify what geometry needed to be included in the calculation. Recent advances in geometry inferencing and selection have simplified the process. At the same time the underlying mathematics have improved to solve more complex cases making direct editing easier and more robust.

we’re combining geometry, rules and the geometric relationships that appear in a design and solving them at the time of editing

At Siemens PLM we took this drive into direct modeling technology further when we announced synchronous technology. We believe that NX 6 Design Freedom powered by synchronous technology takes this type of modeling beyond simple “direct modeling” that is purely a modification of the topology used in a design. It takes us into what we are calling synchronous modeling. What we’re doing is combining geometry, rules and the geometric relationships that appear in a design and solving them at the time of editing. We automatically recognize and maintaining relationships such as tangency and symmetry in real-time as the geometry is modified. This gives us the ability to make model changes that can’t be done with traditional direct modeling.

Having said it’s clear that there are still cases that are not suitable for direct interaction. That’s why we continue to invest in the underlying architecture and the user interaction, allowing users the ability to work the way they want. Our goal inside NX is to give designers the freedom to work the best way to get the job done, offering parametric history-based and history-free approaches to design. We’re not saying direct modeling is the only approach to design, we’re really saying you need the best of both worlds.

What is the status of JT as an open file format? Does JT have a new role to play in the context of a big company such as Siemens?

With over five million JT-enabled licensed software applications installed worldwide, JT is the most widely used lightweight 3D data format for product visualization, collaboration and interoperability throughout the CAD and PLM industries, making it very useful in today’s multi-CAD environments.

in December 2006, the comprehensive JT File Format Reference document was published and made available for free download

As for its status as an open format, a couple of items come to mind. First of all, the JT Open Program is accessible to all organizations and makes the JT toolkit available to all members – including companies that directly compete with Siemens PLM Software. Second, in December 2006, the comprehensive JT File Format Reference document was published and made available for free download from the Siemens PLM Software web site. This completed the next logical step in establishing a common, open 3D language for the PLM industry to share product related information and further established JT as a long-term data retention format.

As for JT’s role within Siemens, the company has been a long-term user of JT with an internal user community sponsored by its Corporate Technology department that provides advocacy and support for the growing JT usage throughout the global Siemens enterprise.

What sort of changes should users expect in their CAD system in the next few years?

I think that there are a number of ongoing challenges that users are looking for their vendors to address.

In terms of modeling technology, users continue to seek solutions that are quick and easy to work with especially when working with geometry that they haven’t designed. This may or may not have parametric history, so the freedom to work directly on models with a level of intelligence that gets added at edit time rather than at creation time.

users continue to seek solutions that are quick and easy to work with especially when working with geometry that they haven’t designed

There will always be improvements to usability, such as the display of relevant information to support the decision process, or alternative input devices (it’s hard to see that the traditional 2-D mouse and keyboard approach will be the only way forward).

I believe you will also see more use of alternative representations of data, polygon modeling that has traditionally been targeted at reverse engineering applications could have a wider use in CAD technologies. One thing is clear, nobody in this industry is standing still.

I would like to thank Paul Brown for taking the time to answer my questions. A special thanks also to Dora Smith for her valuable support in putting together this interview. If you have any questions for Paul or for Novedge, please leave a comment below and we will be glad to answer.

Franco Folini

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

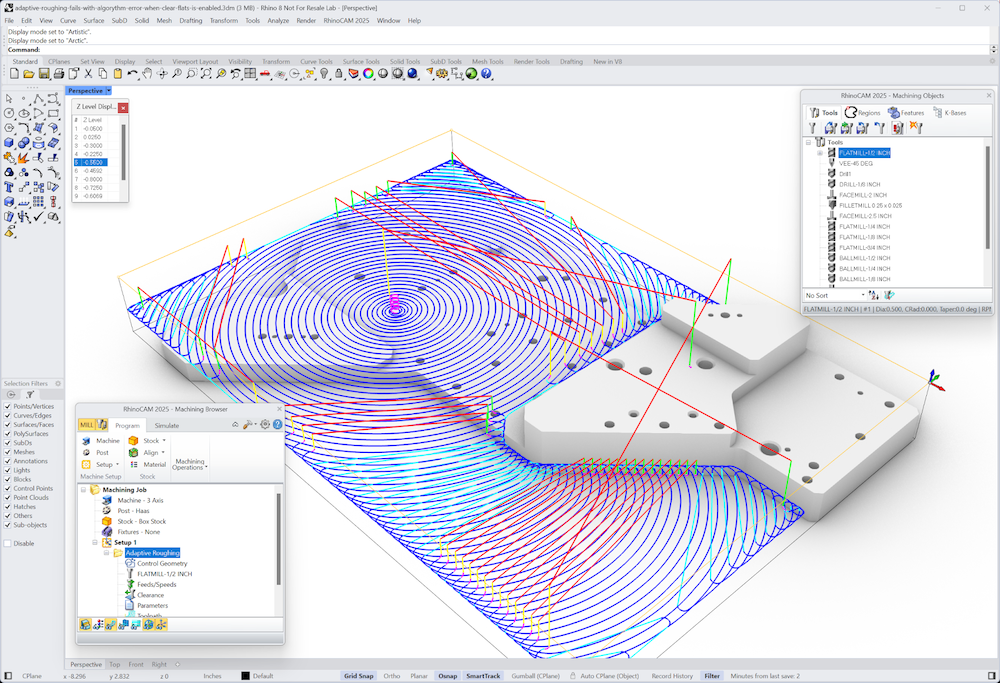

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …