Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

EikoSim: Bridging The Gap Between Simulations And Testing In Structural Mechanics

July 08, 2021 4 min read

Novedge : Tell us a little bit about EikoSim and what you do.

Florent Mathieu: We are a startup company who aims at bridging the gap between simulations and testing in structural mechanics. We want to help simulation engineers and managers who are tired of producing models but have no way of being certain they are credible. To achieve that, we developed a unique image processing software that creates a direct path from measurement information to the simulation mesh. It's based on Digital Image Correlation (DIC) but has since evolved into a more general communication platform to link tests and simulations.

Novedge: Tell us about EikoSim’s history.

Florent Mathieu: At the time of Eikosim's creation, DIC had already developed to some extent. We were doing research work with Airbus at the University of Paris-Saclay’s LMT laboratory, and saw that when using DIC, engineers kept stumbling into a recurring problem, something they called “two screen syndrome”. The screen with the DIC results had a nice cloud of points with color maps; meanwhile, a different screen had the FEA (Finite Element Analysis) model on it. DIC was good for communicating test results, but not so good at comparing quantitively with an FEA model. The comparison is more of a qualitative process and needs to be visualized using points on a mesh. Engineers usually have a huge amount of data from simulations, a large amount of data from DIC – images plus data points – and to measure the differences they have to export a few chosen data points to Excel and plot it out there. From this massive amount of information, they end up with just a few kilobytes of data for comparison. We were starting to realize that the technology we had in our hands had a role to play to make these engineer's lives easier.

Novedge: What kind of professionals do you target with your solutions?

Florent Mathieu: We work with industries such as aeronautics, space, defense, automotive. The main users of our solutions are test/simulation engineers who want to communicate using an easier workflow during the development phase. In the end, their goal is to achieve faster development by taking the right decisions based on the simulation model results.

Novedge:What are the main products you develop and what are their functions?

Florent Mathieu: EikoTwin can be broken into three main solutions:

- EikoTwin DIC is an image processing software, and allows the user to measure the displacement/strain field of a test piece directly on its simulation mesh, as well as aggregate other measurement information.

- EikoTwin Digital Twin corrects the simulation model based on that measurement information, in order to obtain the best correlation possible.

- EikoTwin Virtual assists engineers during the test preparation phase, especially if a large number of cameras are involved.

Novedge: What are the main benefits of validating a model in a Digital Twin?

Florent Mathieu: The idea of a Digital Twin is to bring together physical and digital information to make an informed choice based on the model. It's not only about comparing datasets but really identifying error sources and correct them within that platform. A Digital Twin does this by automatically replaying different model configurations until the model fits the expectation. It's a lot less hassle than the usual trial-and-error procedure simulation engineers are used to. Using image data, which is a lot richer than traditional sensors, makes this process largely more robust.

Novedge: Do you provide assistance throughout the process?

Florent Mathieu: Yes, we usually provide assistance, especially for the first projects. We want to make sure our customers get autonomous as soon as possible, because that's when they obtain the most gain.

Novedge: How necessary is training?

Florent Mathieu:All of our users can follow a 1.5 days training session to have a standard understanding of how the software works and a first use experience. Users can also train on more advanced use cases that we offer in a dedicated platform.

Novedge: Can you share one of your client's success stories ?

Florent Mathieu: We recently worked with Faurecia who had a challenging case to correlate, with particularly small displacements and a non-homogeneous strain field. That was the first time they used image processing to acquire test information. They were surprised how fast they obtained the results, especially for the time gained during post-processing. The CAE engineer told us he correlated his model in a week, when it usually takes him over a month of trial-and-error. They were quite impressed with the performance.

Novedge: Are your solutions suited for both big and small businesses?

Florent Mathieu: It doesn't really matter since the key thing is simulation maturity level. If a customer has a good maturity level and has trouble correlating to test results, there's probably something we can help with. It happens more often that we find it a large corporations but a lot of smaller companies are now managing simulation models.

Check out our latest Novedge Webinar where EikoSIm's CEO, Florent Mathieu, explains how it is possible to bridge the gap between simulation and testing.

Connect with our experts at 1-866- 362-8970 to explore EikoSim products and start bridging the gap between simulations and testing now!

Products Mentioned in this Article

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

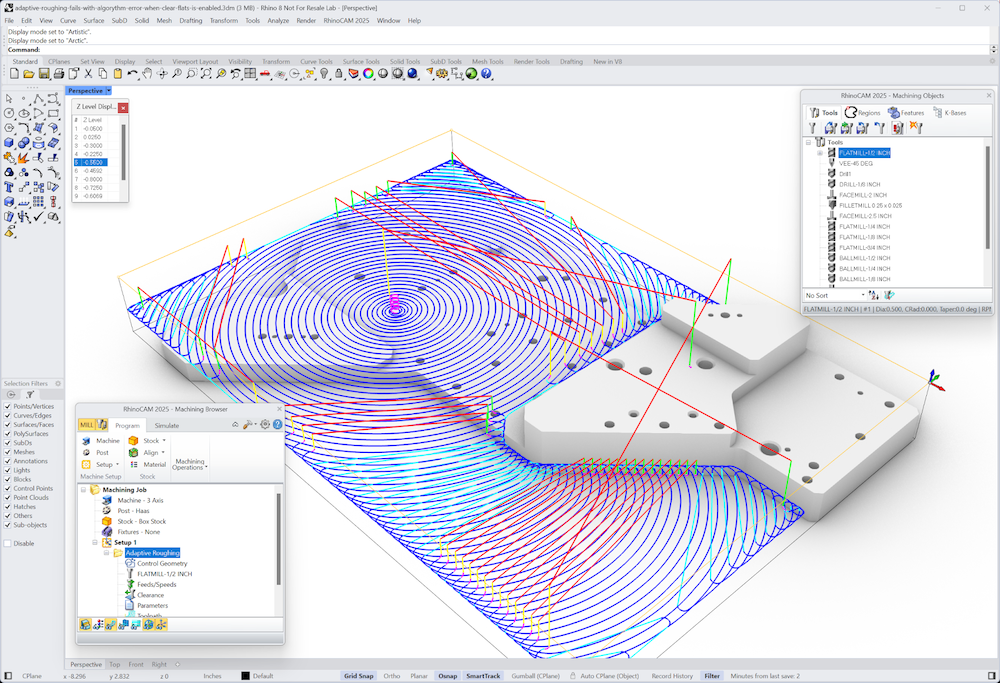

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …