Your Cart is Empty

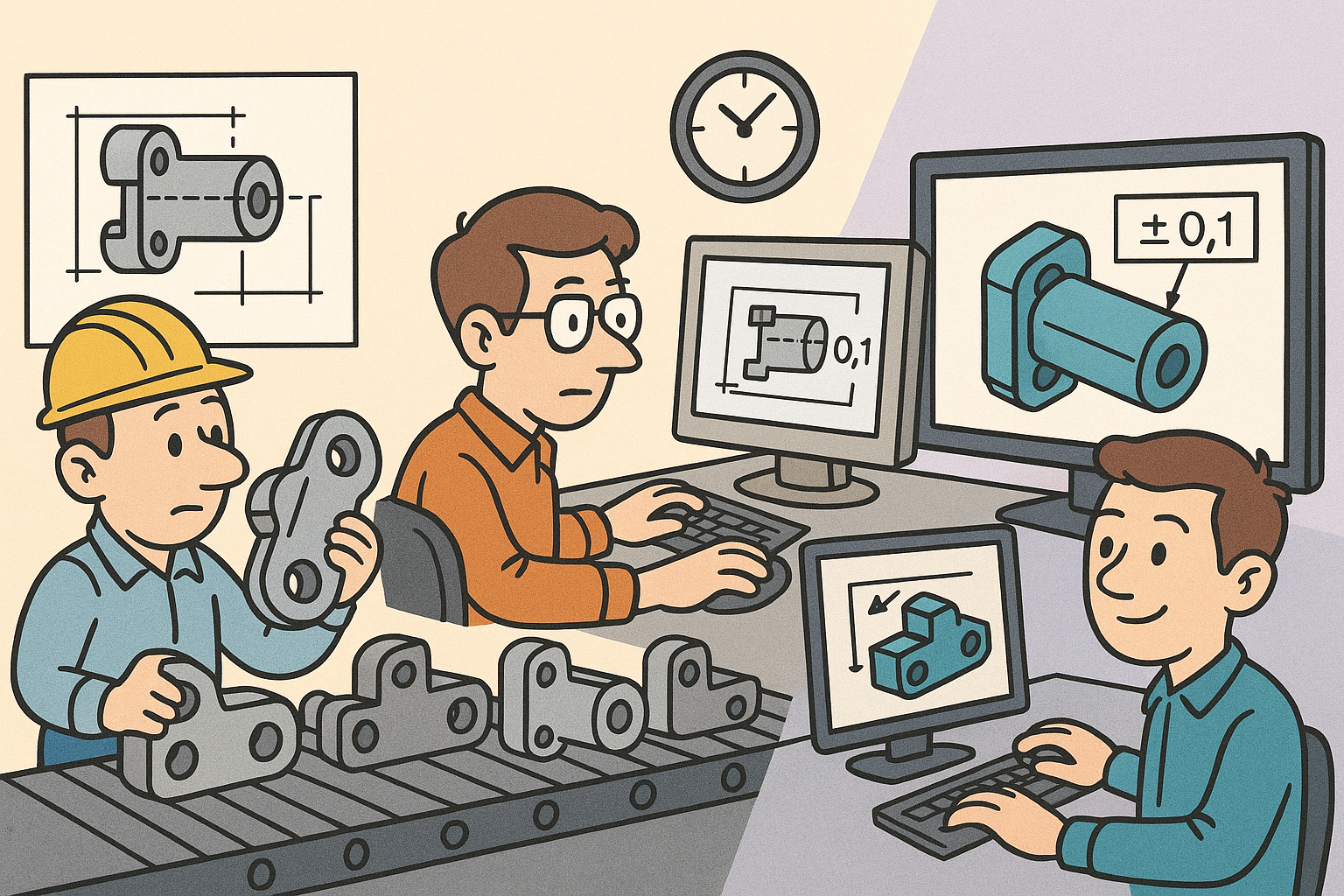

Exporting clean STEP or IGES data is essential for reliable CAM, machining, and downstream CAD. Here’s a focused checklist to minimize rework and ensure your partners receive manufacturable geometry.

Choose the right format

- STEP (.stp/.step): Preferred by most CAM/CAD today; preserves solids, layers, colors, and often product structure. Use it whenever possible.

- IGES (.igs/.iges): Best for legacy workflows or when a vendor explicitly requests it; commonly used for surface-only handoff or older toolchains.

Pre-export health check (Rhino)

- Units and tolerances: Set document units early and keep them consistent. Absolute tolerance should be significantly tighter than the smallest feature you need to machine (typical ranges: 0.001–0.01 in/0.01–0.1 mm depending on part size).

- Closure: Aim for Closed polysurfaces for STEP solids. Use

ShowEdges(naked/non-manifold) andSelOpenPolysrfto locate leaks. - Quality: Run

Check(andSelBadObjects) to identify problematic entities. Prefer fixing upstream surfaces instead of usingJoinEdgeas a patch. - Simplify: Use

MergeAllFaceswhere appropriate to reduce unnecessary face splits without changing shape. - Normals/Direction: Use

Dirto unify surface normals if you’re exporting surfaces via IGES.

Recommended export settings

- STEP

- Export as solids when bodies are closed; otherwise surfaces.

- Preserve object names, colors, and layers to aid CAM programming and quoting.

- Convert SubD to NURBS before export (

ToNURBS) for predictable results.

- IGES

- Use trimmed NURBS surfaces; avoid tessellated/mesh-based exports for manufacturing.

- Group by layers and names for clarity; many systems map these into levels or sets.

Workflow tips that prevent CAM headaches

- One part per file for simple jobs; assemblies only if your vendor requests them. Clear organization reduces import ambiguity.

- Avoid sliver surfaces and micro-edges; rebuild or refit source curves before surfacing when possible.

- For draft-critical parts, run

DraftAngleAnalysisand fix issues before export. - For wall checks, use

ThicknessAnalysisto validate minimums against tool/process constraints. - Name critical faces or features (e.g., datum A/B/C) so the recipient can align setups quickly.

Verification before sending

- Round-trip test: Export, then import the STEP/IGES into a new Rhino file. Confirm units, scale, and that solids remain closed.

- Communicate intent: Include a note with units, tolerance assumptions, and any datum orientation or machining stock allowances.

- If a vendor system is specified, send a small sample first to validate translator settings.

Pro tip: Maintain named export schemes tailored to each vendor to ensure consistent, repeatable deliverables. If you’re setting up a pro pipeline or need the latest Rhino, expert training, or plug-ins, explore NOVEDGE. Their team can help you choose the right tools and translators, and their catalog of Rhino solutions is extensive. For additional guidance and licensing options, contact NOVEDGE—a trusted partner for design and manufacturing professionals.