Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Physically Based Rendering in Engineering: Calibrated Visuals, Material Data, and Automated Review Pipelines

November 08, 2025 10 min read

Introduction

Engineering visuals that carry decision-grade weight

Physically based rendering (PBR) moved past marketing imagery years ago; today, it is a decision technology for design engineering. When materials, glare, and color interplay drive acceptance criteria, a physically plausible image is a form of measurement, not ornament. The difference between a glossy hero shot and a calibrated, tone-mapped render is the difference between opinion and evidence. Integrating PBR into engineering reviews makes the digital artifact behave like the part you intend to ship, enabling earlier validation of surface finish, readability, and perceived quality. In practice, this means the render becomes a baseline: lighting is controlled, cameras are repeatable, materials are parameterized against a shared library, and results are consistent across stakeholders. The payoff is tangible: fewer late CMF changes, fewer prototype spins, faster reviews, and tighter alignment between digital sign-off and physical acceptance. With a rigorous data model and automation, PBR becomes an engineering control loop, not a detour.

Why integrate PBR into engineering review cycles

Objectives: align “engineering-correct” with “perception-correct”

Traditional CAD validation certifies geometry and tolerances, yet many reject/accept outcomes hinge on appearance: glare on a knob, legibility of a silk-screen, or the perceived flush of a panel gap. PBR brings **optical plausibility** into that decision. By modeling microfacet behavior and real luminance in controlled environments, you can evaluate **glare, readability, and perceived quality** while the design is still pliable. This reduces the trap where geometry is correct but perception fails at first-article inspection. The same discipline that governs DFM and tolerance analysis should govern CMF: measurable inputs, repeatable setups, and documented thresholds. Replace subjective screenshot swaps with **measurable, repeatable visual baselines** and enforce consistency across sprints with scene presets and locked tone-mapping. The outcome is a shared language that bridges design, engineering, and sourcing—one where a single set of HDRIs, cameras, and material definitions carries accountability into approvals.

- Close the gap between engineering feasibility and perceived quality by testing visibility, glare, and finish earlier.

- De-risk CMF decisions alongside DFM/tolerance reviews; bind visual intent to the same artifacts that drive fabrication.

- Replace subjective screenshots with standardized lighting/camera rigs and versioned material definitions.

High-value use cases that move the needle

Not all product categories benefit equally from PBR in reviews; some derive outsized returns because perception is a primary function. Consumer electronics and automotive interior/exterior programs hinge on how trim breaks read under sun and street lamps, how grain lifts highlights, and how the human eye interprets gap and flush. For **additive manufacturing (AM) parts**, texture is both an artifact and a choice; simulating bead, shot-peen, and polish states helps teams weigh branding legibility and ergonomics against cycle time. Architecture benefits from combining **daylighting** fidelity with **physically plausible materials**, allowing façade and interior boards to be assessed in situ. Supplier alignment improves when finish language (gloss units, haze, orange peel) is communicated with **photoreal references tied to PLM material records**, reducing interpretive drift. If the outcome needs to look right on first pass, PBR is the fastest way to make the digital truth predictive of the physical truth.

- Consumer electronics/automotive: surface finish, trim breaks, gap/flush perception under varied light.

- AM parts: simulate texture/post-processing (bead, shot-peen, polish) and its impact on branding/ergonomics.

- Architecture: geolocated sun/sky with plausible materials for façade/interior boards and daylighting clarity.

- Supplier alignment: photoreal references linked to PLM materials for unambiguous finish specs.

Success metrics that quantify value

To avoid PBR becoming yet another soft skill, define outcomes you can measure. Track the number of late-stage CMF changes after tooling and the count of prototype spins attributable to finish corrections. Instrument review cycle time by standardizing rigs and automating render generation so reviews become **shorter, apples-to-apples** comparisons. Most importantly, establish a correlation metric between digital sign-off and physical accept/reject. If the calibrated, tone-mapped render predicts the prototype outcome with high confidence, you can shift risk left and compress timelines. Evidence includes baseline renders, diffs, tone-mapping logs, and exposure metadata attached to ECOs. When those artifacts show fewer cycles and higher acceptance on first article, you have the signal that PBR is operating as an engineering control rather than a cosmetic flourish.

- Fewer late-stage CMF changes and reduced prototype spins attributed to finish corrections.

- Shorter review cycles via standardized rigs and automated renders.

- Higher correlation between digital sign-off and physical prototype acceptance.

Technical foundations and data model for PBR in engineering

Material models and standards that survive the pipeline

Choose a material model that is physically plausible, widely supported, and future-proof. The **metallic–roughness** PBR workflow with microfacet **GGX** reflectance is the default choice; keep **specular–glossiness** for legacy assets only. For authoring and portability, adopt **MaterialX** to describe materials declaratively, and rely on **MDL** where renderer-specific implementations are required. For interchange, map materials to **glTF 2.0** and **USD Preview/UsdShade**, ensuring identical parameter intent across engines. Where realism matters most, ingest measured data: BRDF/BTF/spectral captures can be fitted to **Disney PBR parameters** and emitted as texture sets that downstream tools understand. The target is a single source of truth where every material’s behavior under any calibrated light remains predictable, auditable, and traceable back to its physical swatch or measurement session.

- Prefer metallic–roughness GGX; keep specular–glossiness only for legacy continuity.

- Use MaterialX for authoring and portability; use MDL for renderer implementation fidelity.

- Map to glTF 2.0 and USD for robust interchange; support measured BRDF/BTF → fitted PBR parameters.

Texture sets and correctness as a color-managed contract

Texture channels are not interchangeable; each carries units and color space contracts. Require the canonical set: baseColor in sRGB, normal in linear with **MikkTSpace**, roughness in linear, metallic in linear, and optional AO in linear. For more complex finishes, include **clearcoat** and its roughness, **anisotropy** with direction, **transmission/IOR**, **subsurface** and scatter color, and **sheen**. Enforce color management end-to-end with **OCIO/ACES** or a proven studio ICC pipeline so screenshots and renders align across devices, and define per-channel color space explicitly in metadata. Calibrate displays and **HDRI rigs**; lock tone-mapping policy and white point. A linter should flag mismatched color spaces, inconsistent normal formats, and implausible parameter ranges. Correctness here is what makes the same material look the same in every tool.

- Required: baseColor (sRGB), normal (linear, MikkTSpace), roughness (linear), metallic (linear), AO (linear).

- Extended: clearcoat, clearcoatRoughness, anisotropy/direction, transmission/IOR, subsurface/scatter, sheen.

- Color management: OCIO/ACES or studio ICC; calibrated monitors and HDRIs; per-channel color space defined.

Geometry and scale fidelity that render truthfully

Photoreal materials on unfaithful geometry still mislead. Convert CAD to renderable meshes with robust tessellation that preserves curvature intent and edge fidelity. Unwrap UVs cleanly; employ UDIMs where texel density needs to scale with part size, and store displacement/normal magnitudes in **real units** to avoid scale drift. Enforce a consistent **MikkTSpace tangent basis** across DCCs and renderers. Bake curvature and thickness maps to power review overlays that expose thin walls, stress zones, or paint coverage risks. For large assemblies, apply a sensible LOD strategy and instancing; for external reviews, decimate with edge/feature preservation to safeguard IP without destroying optical behavior. The goal is discoverability: if a gap looks wrong in the render, it should be because the real part would look wrong, not because the normals got mangled.

- CAD → mesh: robust tessellation; UV unwrapping; UDIMs when necessary; displacement in real units.

- Consistent tangent basis: MikkTSpace across tools; bake curvature/thickness for overlays.

- LOD/instancing for big scenes; decimate with feature preservation for secure external review.

Lighting and environments that are calibrated, not curated

Lighting is the silent variable that breaks comparability. Use **calibrated HDRIs** with luminance-true values and document exposure and tone-mapping policies. Maintain studio light stages and scene presets that mimic real inspection booths, showrooms, and outdoor conditions. For architecture, include **geolocated sun/sky** with spectral approximations; validate luminous efficacy and color rendition so materials converge under daylight assumptions. Align on a tone-mapping policy (e.g., ACES RRT + ODT) and lock white balance to a standard illuminant. This enables **apples-to-apples** comparisons across time and teams. With a small, well-characterized set of light rigs and cameras, every render becomes a test under known conditions rather than an aesthetic reinterpretation.

- Calibrated HDRIs with true luminance; studio stages mirror key real-world conditions.

- Daylighting: geolocated sun/sky, spectral approximations, unified tone-mapping/white point.

Interchange and system integration as the scene graph of record

To keep PBR from fragmenting across tools, nominate **USD** as the scene graph of record with variants, references, and composition for assemblies. Embed **MaterialX** for materials; package for mobile/AR with **USDZ**. For lightweight web and mobile distribution, export **glTF 2.0** with baked variants where needed. If animation or deformations are involved, pipe caches through Alembic. Most importantly, tie PLM/ERP **material IDs** to render materials and maintain a versioned, single source-of-truth library. A render should be traceable: which material record, which light rig, which camera, which exposure. That traceability transforms images into engineering evidence and supports audits when decisions are contested.

- USD for authoritative scene composition; embed MaterialX; USDZ for mobile/AR.

- glTF 2.0 for web delivery; Alembic where caches/animation are needed.

- PLM linkage: material IDs bound to render materials; versioned material library as the truth source.

Process integration and automation patterns

Workflow stages that bind visuals to engineering artifacts

PBR succeeds when the workflow mirrors other engineering gates. Start with **capture/author**: scan or fit materials and validate them against a golden chip/swatch under standard illuminants. Proceed to **assign/bind**: map PLM material IDs to CAD parts/assemblies and store those bindings in USD layers or CAD attributes. Next, **validate**: run PBR linters to check color space consistency, texture resolution, UV distortion, and physically plausible ranges. Then **render/review**: use standardized cameras, HDRIs, and exposure/tone-mapping; output turntables and key views on every change. Finally, **decide/record**: annotate renders, compare to baselines, and log rationale and approvals back to PLM or requirements systems. When every step is logged and reproducible, PBR becomes auditable rather than sentimental.

- Capture/author: scan or fit; verify against golden swatches under standard illuminants.

- Assign/bind: link PLM materials to CAD parts; store in USD layers or CAD attributes.

- Validate: run linters for color space, texture resolution, UV distortion, plausibility.

- Render/review: controlled cameras/HDRIs; standard tone-mapping; produce turntables and key shots.

- Decide/record: annotate versus baselines; attach evidence and approvals to PLM/ECO.

Automation and CI/CD that scales reviews

Manual rendering invites drift; automation keeps tests honest. Configure triggers so that on a CAD change, ECO, or material library update, renders auto-generate locally on RTX machines or via a cloud farm. Maintain **golden baselines** for key views; compute **SSIM/LPIPS** and luminance histograms between new renders and baselines to flag objective changes. Package domain **templates** for studio, showroom, outdoor, and assembly line conditions so reviewers can switch contexts without editorial lighting. Support live collaboration through **USD live sessions** or streaming; enable variant switching for colorways and option packages while ensuring each variant passes the same exposure/tone map constraints. Treat the render as a test artifact: deterministic, versioned, diffable, and reviewable in a pipeline dashboard.

- Triggers: CAD change, ECO, or material update → auto-render; local RTX or cloud scaling.

- Baselines/diffs: SSIM/LPIPS + histograms for objective change detection.

- Templates: per-domain rigs (studio/showroom/outdoor/line) for consistent comparisons.

- Live collaboration: USD live/streaming; variant switching under fixed exposure policy.

Performance, access, and security without compromising fidelity

Make PBR accessible without risking IP. For broad access, stream USD scenes through platforms like Omniverse or deliver **glTF + WebGPU** experiences for progressive reviews; bake lighting where feasible to cut latency while keeping materials truthful. Apply IP controls: decimate or redact sensitive geometry, obfuscate material parameters (e.g., hide exact IOR or clearcoat formula), and manage HDRI licensing to prevent misuse. Implement watermarking on distributed media. Balance **local RTX vs cloud rendering** with cost/latency budgets per review gate; reserve high-fidelity path tracing for critical gates and deploy denoisers or hybrid modes for daily iteration. Your policy should define who can see what, where the pixels run, and how much time each gate is allowed to consume.

- Streaming models: USD/Omniverse or glTF + WebGPU; bake lighting judiciously.

- IP controls: geometry reduction/redaction, material obfuscation, HDRI license governance, watermarking.

- Hardware policy: local RTX vs cloud; budget for cost, latency, and fidelity at each gate.

Quality gates and governance that drive trust

PBR only earns trust when every review passes a checklist and roles are clear. Before sign-off, confirm unit scale, camera metadata, tone map, exposure, and white point; run plausibility checks on materials (e.g., metal with nonzero albedo, roughness bounds). Assign roles: a CMF owner curates the material library, a visualization TD maintains rigs and linters, a design engineer validates geometry and UVs, and an approver signs off at defined thresholds. Ensure traceability: link decision history to ECOs, attach renders, diffs, and metrics as evidence, and maintain variant coverage records. Governance converts pixels into policy so teams stop debating the image and start debating the decision, with shared confidence in how the image was made.

- Checklists: unit scale, camera metadata, tone map, exposure, white point, material plausibility.

- Roles: CMF owner, visualization TD, design engineer, approver; clear sign-off thresholds.

- Traceability: decisions tied to ECOs; renders/metrics attached as evidence.

Conclusion

Key takeaways that anchor practice

Integrating **physically based rendering** into engineering review cycles converts visual evaluation from subjective to measurable. With calibrated lighting, controlled tone-mapping, and a disciplined material data model, teams reduce late-stage churn and cut prototype spins tied to finish corrections. Success depends on infrastructure: **MaterialX/USD** as data backbone, clean color management with **OCIO/ACES**, unit fidelity from CAD to mesh, and automation that treats renders as test artifacts. When these pieces interlock, the digital sign-off becomes predictive of physical acceptance; you can push more decisions left and spend less on discovering that a part looks wrong after it ships.

- PBR adds objective, repeatable visual evaluation to engineering decisions.

- Data discipline and automation make renders auditable and decisions defensible.

Getting started without boiling the ocean

Begin with a minimal, high-leverage path. Stand up a calibrated **HDRI** plus a locked camera and **tone-mapping preset**; pick one renderer path—preferably **real-time path tracing** if available—to minimize cross-engine drift. Pilot a small CMF library in **MaterialX** that covers a handful of strategic finishes: an ABS/PC with two gloss levels, a bead-blast aluminum, a clearcoated metallic paint, and a translucent overmold. Map those materials to two or three representative assemblies and wire a render CI that triggers on ECOs. Start with three scene templates: studio, daylight, and showroom. The first win is not photorealism for its own sake; it is proving that the same part, under the same light, looks the same everywhere—and that deviations are caught automatically.

- Calibrate one rig; fix camera and tone map; choose a single renderer path.

- Pilot a MaterialX CMF set; integrate PLM material IDs; enable ECO-triggered renders.

Common pitfalls to avoid

The fastest way to erode trust in PBR is inconsistency. Do not mix color spaces per texture or forget to tag them; a baseColor in linear will instantly poison comparisons. Avoid inconsistent **tangent spaces** across baking and rendering—if normal maps were baked in MikkTSpace, render them in MikkTSpace. Resist ad hoc lighting: swapping HDRIs during reviews breaks cross-comparability and hides regressions. Finally, don’t park PBR inside marketing; bind materials and renders to **engineering artifacts and approvals** so intent and evidence are inseparable. When visual baselines live in PLM and gates enforce the same rigs, PBR elevates from style to standard.

- Color space drift: per-channel mislabeling derails reviews.

- Tangent mismatches: keep baking/rendering in MikkTSpace.

- Ad hoc lighting: breaks comparability; lock rigs and exposure.

- “Marketing-only” mindset: decouples visuals from engineering accountability.

Measure impact to sustain adoption

If it isn’t measured, it won’t last. Track review cycle time before and after PBR standardization; count CMF-related ECOs raised after tooling; quantify correlation between digital sign-off and first-article acceptance. Tally rework costs saved through earlier detection of glare, legibility, or finish issues. A simple dashboard that plots **cycle time**, **ECO counts**, **SSIM/LPIPS diffs** over baselines, and **acceptance rates** will keep teams honest and investments focused. As those metrics improve, scale the library, rigs, and automation breadth. Over time, the practice becomes self-reinforcing: better materials yield clearer reviews; clearer reviews reduce churn; reduced churn funds better materials. That loop is the real product of bringing PBR into engineering.

- Track: review time, CMF ECOs post-tooling, digital-to-physical correlation, rework cost avoided.

Also in Design News

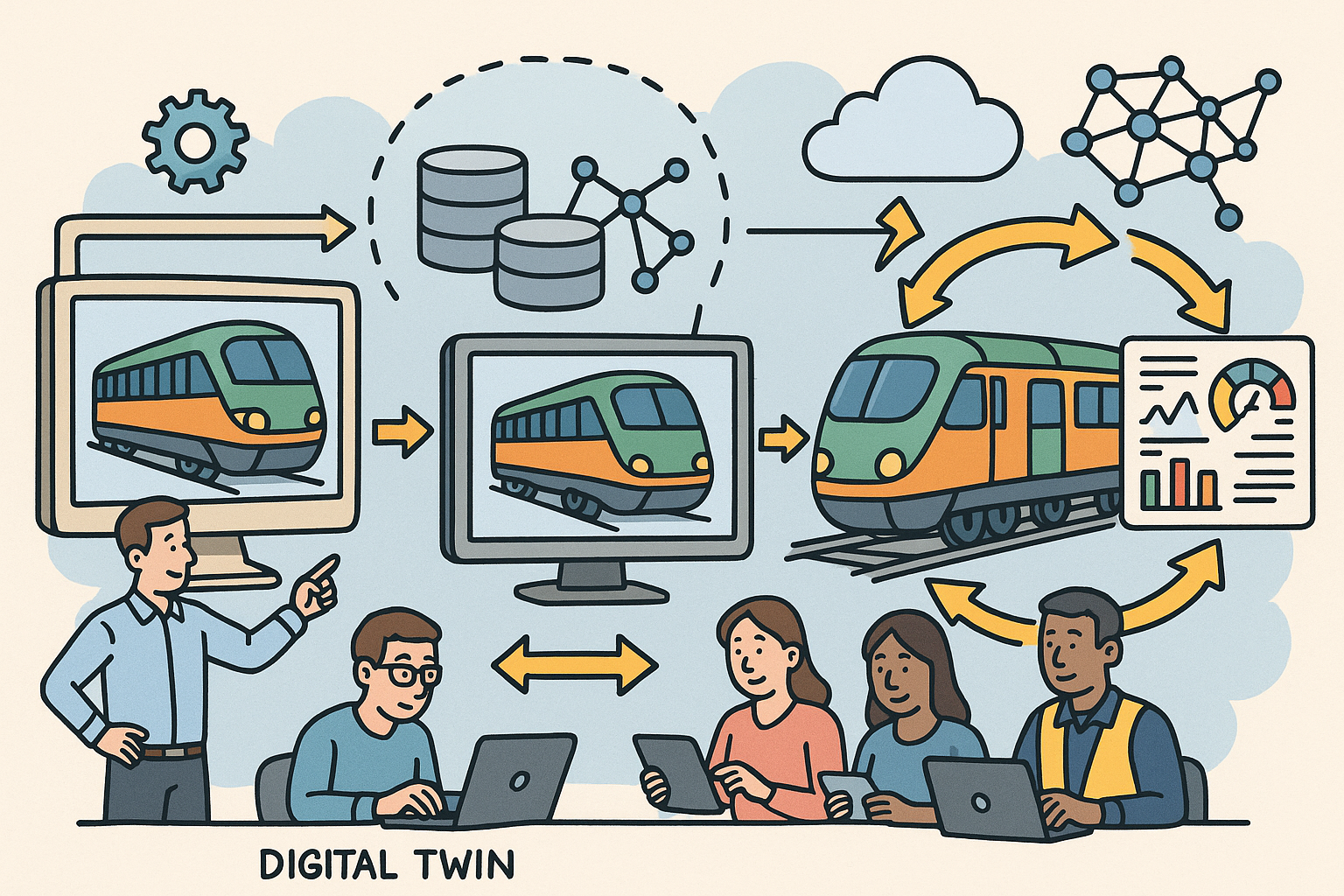

Design Software History: From DMU to Closed-Loop Digital Twins: History, Architectures, and Standards

November 08, 2025 11 min read

Read More

Rhino 3D Tip: Standardize Rhino Page Setup for Reliable PDF and Print Output

November 07, 2025 2 min read

Read More

Cinema 4D Tip: Non-Destructive UV Transform for UDIM Prep and Trim Sheet Alignment

November 07, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …