Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Mastering Creo: Integrating Generative Design with Real-Time Multiphysics and AI-Driven Optimization

May 19, 2025 5 min read

The push toward digital continuity has made it imperative for engineers to close the gap between design intent and performance proof. PTC Creo responds by fusing high-order analytics and CAD authoring into a single canvas, ensuring that each sketch, feature, and assembly decision is informed by live, quantitative insight.

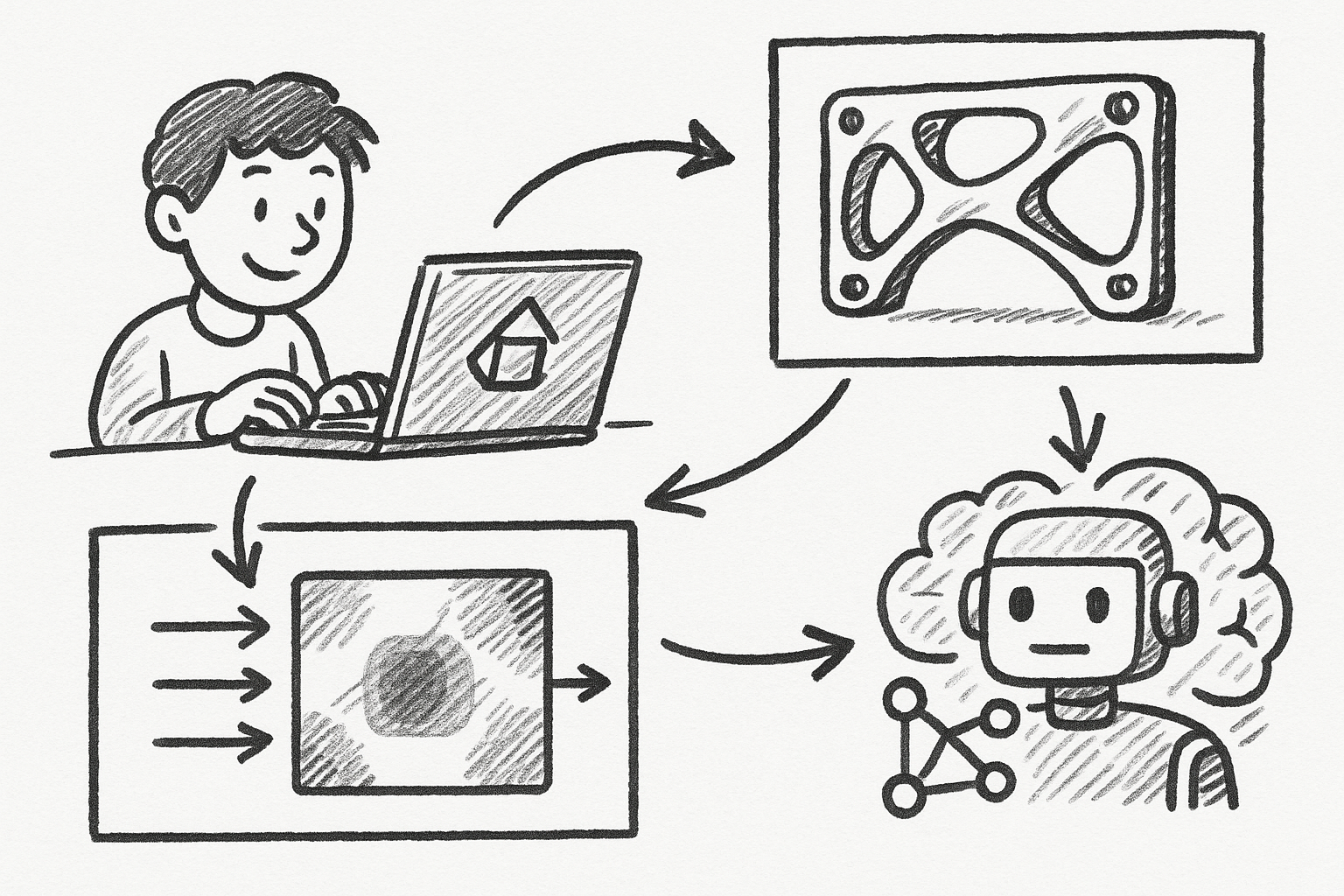

Generative Topology Optimization Tied to Live Parameters

Traditional topology optimization tools often force the designer to leave the parametric model behind, generating abstract meshes that have to be reverse-engineered into manufacturable surfaces. Creo removes that disconnect by running its iterative, FEA-driven mass-reduction loops inside the parametric history tree. Dimensions, equations, family tables—everything remains editable while the solver iterates.

Protected regions can be designated with a one-click “no-fly zone” command. Mounting holes, datum interfaces, or fluid passages remain untouched, while the surrounding material is sculpted toward weight or stiffness targets. Performance goals themselves can be altered mid-run: if a late project decision requires a new safety factor or natural frequency, the solver recalibrates without restarting, saving hours of non-productive compute time.

Upon convergence, the optimizer branches manufacturable variants linked to different production strategies—powder-bed fusion, five-axis machining, or hybrid approaches. Each branch opens with a dashboard that tracks:

- Predicted build cost, including machine amortization and post-processing labor.

- Resultant mass and center-of-gravity shift relative to the baseline model.

- Surface quality index flagging areas where additional finishing steps may be required.

Reverse synchronization deserves special mention. When the solver discovers a non-intuitive rib pattern or lattice distribution, those contours populate editable features in the base model tree. Engineers remain in full control, free to tweak fillet radii or draft angles without breaking the optimization lineage. The outcome is a continuous feedback loop where topology decisions and dimensional edits inform each other in real time.

Real-Time Multiphysics Simulation Workspace

Designers rarely have the luxury of validating thermal, structural, and fluid behaviors in isolation. Creo’s multiphysics workspace stacks these analyses within a single viewport; boundary conditions propagate across domains with no export-import friction. A drag-and-drop material selector automatically inserts coupled properties such as temperature-dependent modulus or viscosity into the solver matrix.

The user experience revolves around GPU-accelerated previews. A coarse mesh spins up within seconds, streaming deformed shapes, pressure contours, or heat maps as the designer drags a dimension handle. Refinement continues silently, stepping through adaptive meshing while edits continue. Engineers therefore operate on a continuum—from sketch, to simulation preview, to high-fidelity result—without modal interruptions.

Scenario templates accelerate adoption. Selecting “heat sink” pre-loads natural convection coefficients, assigns aluminum alloy libraries, and applies ambient PCB temperatures pulled from a Windchill dataset. Similar shortcuts exist for pressure vessels and pump impellers, compressing what once took dozens of dialog boxes into a two-minute setup.

One hallmark of the workspace is its confidence band overlay. Solver uncertainty stemming from material variance, mesh discretization, or load scatter is rendered as translucent zones surrounding stress or temperature plots. Engineers can visually gauge whether the current factor of safety is being consumed by model fidelity or by actual load demand, empowering smarter decisions on whether to mesh finer or add material.

AI-Enhanced Sensitivity & Design-of-Experiments Engine

The moment a part file is saved, Creo’s machine-learning engine begins parsing its geometry features alongside metadata from similar legacy projects. Without any user input, it generates a ranked list of driving parameters—wall thickness, fillet radius, lattice density—that historically dominated performance outcomes for comparable parts. The first simulation therefore starts on informed footing instead of guesswork.

Users can request an automatic Design-of-Experiments sweep. The tool composes a fractional-factorial matrix, trimming out low-impact interactions to cut compute cycles by up to 70%. While the cloud solver crunches, live Pareto plots populate in the side panel:

- X-axis may depict mass or material cost; Y-axis often tracks peak Von Mises stress or thermal resistance.

- Dragging a data point updates the CAD model to the corresponding parameter set and triggers a fast meta-model check rather than a full FEA rerun.

Because the engine trains surrogate models—Gaussian process regressors, radial basis functions, or neural nets—engineers can perform dozens of what-if inquiries in seconds. The surrogate’s prediction error is continuously benchmarked against ground-truth FEA results; once the error band exceeds tolerance, the system cues a targeted high-fidelity solve and assimilates the new data, refining its accuracy.

Cloud-Distributed Solver Farm Integration

High-resolution CFD or nonlinear contact solves can choke a local workstation for hours. Creo converts that bottleneck into a background task with a single cloud dispatch button. A lightweight proxy model stays resident on the desktop, updating with streamable result packets—stress hotspots, vortex shedding frequencies—well before the final iteration finishes.

The queue manager interrogates each pending job, matching it to optimal hardware: GPU clusters for explicit dynamics, high-core CPUs for eigenvalue extraction, or mixed architecture nodes for coupled problems. Deadlines feed into the algorithm as hard constraints, reallocating cores mid-analysis if resource contention threatens delivery targets.

All data traffic is AES-256 encrypted, with optional ITAR compliance modes that pin jobs to geographically restricted data centers. Intermediate results arrive as delta compression streams, minimizing bandwidth while enabling early design pivots. Consumption metrics roll directly into Windchill cost dashboards, giving project managers a real-time read on analysis spend versus budget.

Rule-Based Verification & Code Compliance Toolkit

Engineering brilliance means little if a design cannot pass regulatory gates. The compliance toolkit embeds ASME Y14.5, ISO 2768, and company-specific rule sets as declarative expressions. When a fillet violates a minimum radius for fatigue-critical features, the feature turns amber; when a hole pattern misses positional tolerance, a red flag appears. Feedback is instantaneous, eliminating end-of-project surprises.

Batch verification covers entire assemblies. Upon completion, a scorecard summarizes pass/fail counts and hyperlinks directly to non-compliant geometry—no need to scroll through the model tree hunting for culprits. Integration with Model-Based Definition means GD&T callouts drive automated stack-up studies, with worst-case and RSS results annotated directly on the 3D PMI.

Export routines generate ready-made certification packages—3D PDF, STEP 242, or JT—pre-filled with compliance evidence. Inspectors receive a navigable model where every requirement links back to automatic verification logs, shrinking audit cycles and instilling confidence that the digital thread remains unbroken.

Conclusion

Individually, each of these capabilities pushes the frontier of design software; together, they create a seamless ecosystem in which ideation, analysis, optimization, and compliance exist on the same timeline. Generative optimization removes excess mass while honoring functional constraints, the multiphysics workspace validates complex interactions on the fly, and the AI-assisted DoE engine distills vast parameter spaces into actionable insights. Meanwhile, cloud solvers keep local machines free, and embedded rule checks guarantee that innovation does not compromise governance.

Teams facing aggressive schedules and stringent performance targets should pilot Creo on their most intricate components. Early adopters consistently report shorter design-to-verification cycles, lower prototype counts, and rapid, quantifiable ROI—often within the very first sprint.

```

Also in Design News

Cinema 4D Tip: Creating Futuristic Visuals in Cinema 4D with Advanced Techniques and Tools

October 27, 2025 3 min read

Read More

Bluebeam Tip: Optimizing Precision with Bluebeam Revu's PDF Measure Tool

October 27, 2025 2 min read

Read More

AutoCAD Tip: Enhancing Efficiency and Precision with AutoCAD's ROTATE Command: Best Practices

October 27, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …