Your Cart is Empty

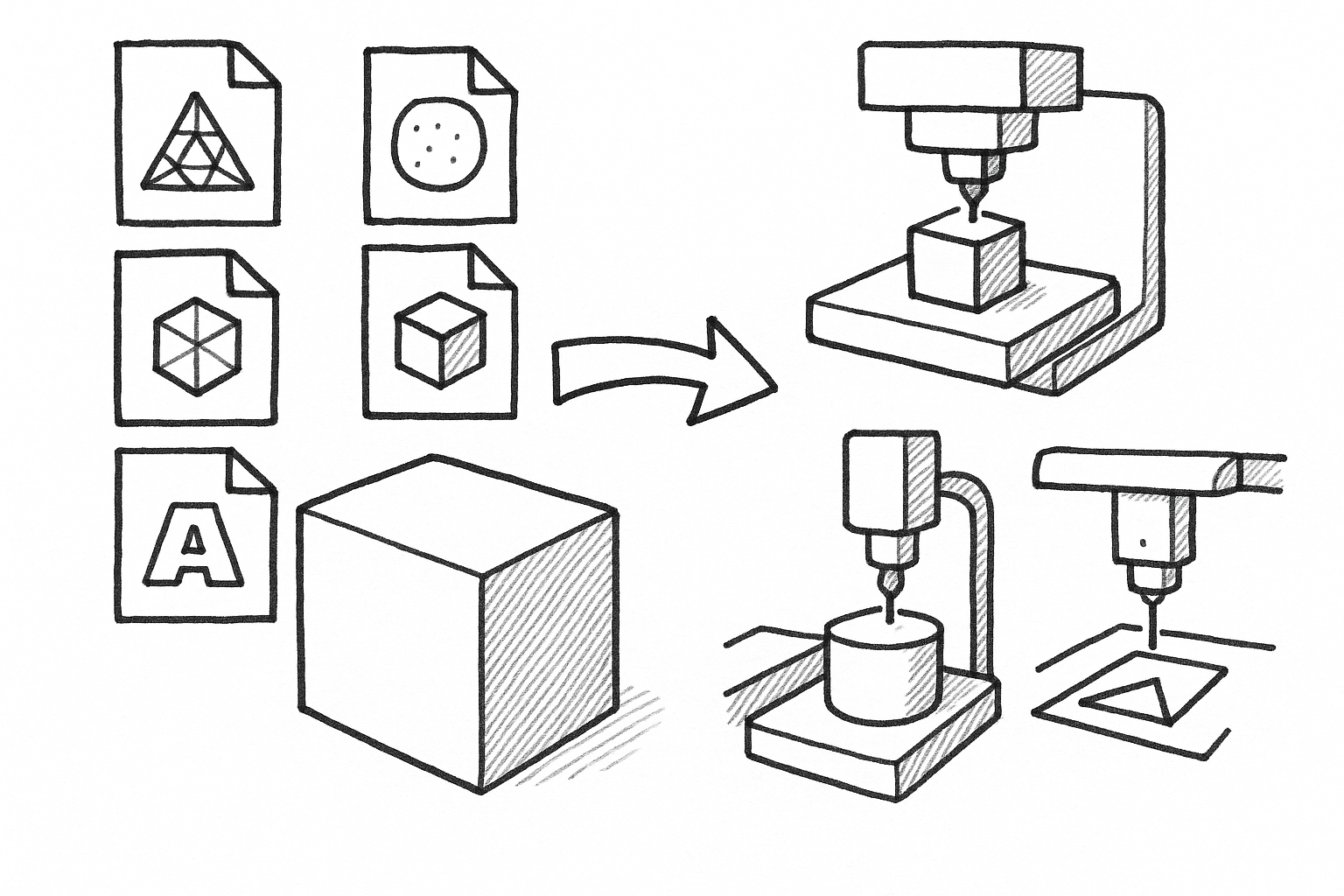

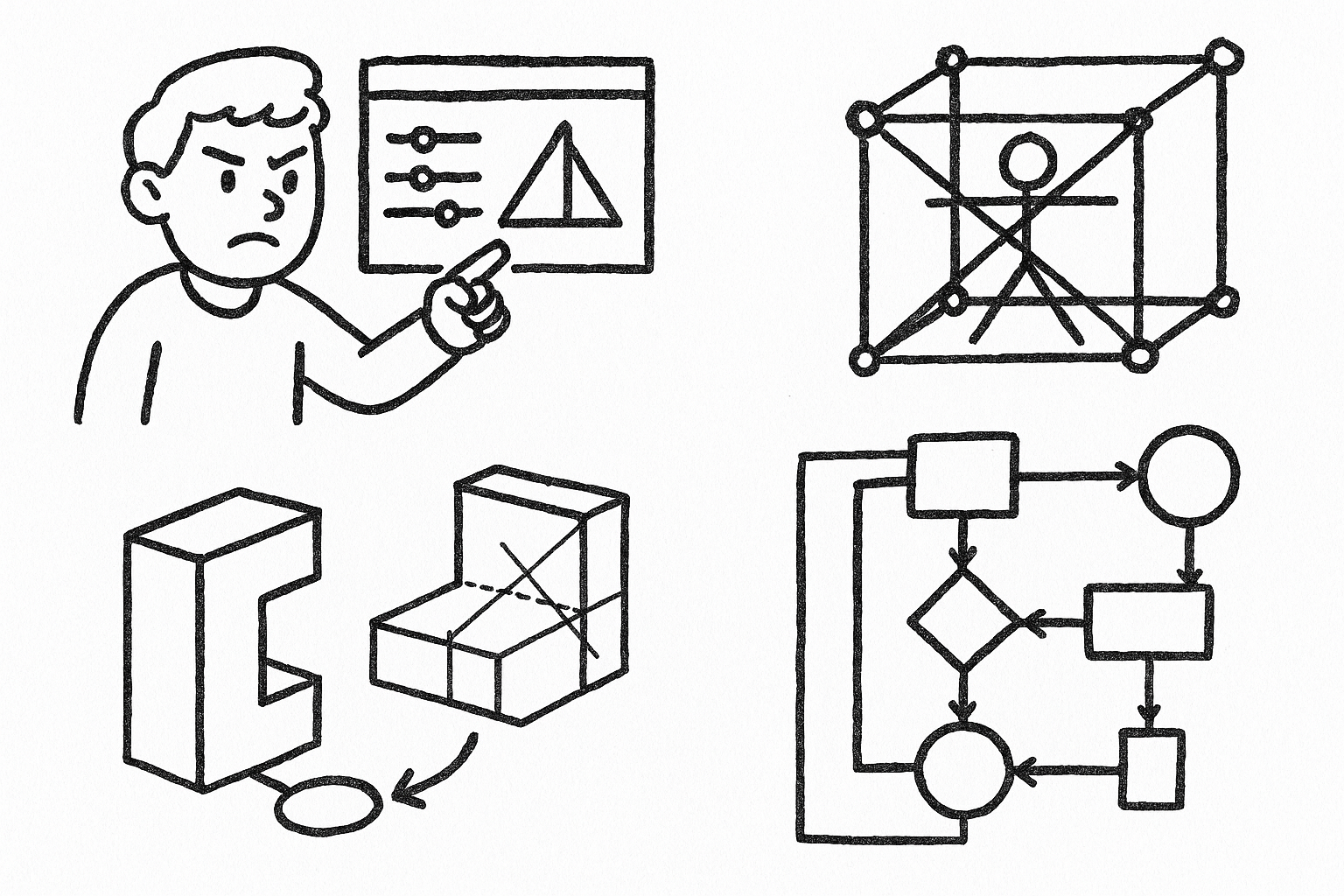

For reliable additive manufacturing and downstream fabrication, the export format you choose in FormZ determines accuracy, printability, and how much post-processing you’ll need. Below are the five most effective export choices, when to use each, and the exact settings and checks that prevent costly rework.

STL: the de facto mesh for most 3D printers

STL remains the most ubiquitous handoff for desktop and professional 3D printers. Its simplicity is its strength: triangles only, no colors or materials, and no parametric baggage. That also means your geometry and tolerance decisions in FormZ carry the entire burden of surface fidelity and feature integrity. When your goal is a fast, predictable toolpath for FDM/FFF or resin, a disciplined STL workflow in FormZ delivers.

Best for

- FDM/FFF and SLA/DLP workflows where color/material metadata isn’t required

- Quick prototypes, jigs, fixtures, and volume parts

Export steps and critical settings in FormZ

- File → Export → STL. Choose Binary STL for smaller files unless your pipeline requires ASCII.

- Units: set to millimeters to match most slicers; lock this early to avoid implicit scale mistakes.

- Faceting controls: tighten angle and chord tolerance to capture small radii without over-tessellating.

- Desktop FDM: typical chord height 0.05–0.2 mm; angle tolerance 5–15°.

- Resin: typical chord height 0.01–0.05 mm; angle tolerance 2–10°.

- Enable Weld Vertices and Unify Normals. STL is triangle-only—ensure triangulation on export.

- Consider a minimum edge length control to suppress micro-facets below your printer’s effective resolution.

Pre-export modeling checklist

- Ensure watertight solids: no non-manifold edges, zero-area faces, or self-intersections.

- Use Object Doctor and Stitch to close gaps; resolve inverted normals.

- Eliminate tiny sliver faces and stray edges below the printer’s minimum feature size (e.g., below 0.4 mm on a 0.4 mm nozzle).

A practical guideline: if your FDM nozzle is 0.4 mm and layer height is 0.2 mm, a chord height around 0.05–0.1 mm resolves curves cleanly without ballooning file size. For resin with 50 µm XY and 50–100 µm Z layers, 0.01–0.03 mm chord height maintains crisp fillets and embossed lettering. Always examine small embossed/engraved features at 2:1 or 4:1 zoom in a mesh preview to confirm edges aren’t “stepped” excessively.

Pitfalls and prevention

- Over-tessellation inflates file size and bogs down slicing; under-tessellation facets curves. Tune chord height to material and layer height.

- Floating or nested bodies become unintended separate parts; group or boolean-union when they must print as one.

- Inconsistent normals can yield strange shading and, in rare cases, confused shells. Always unify.

Downstream guidance

- Validate with a mesh analyzer such as Netfabb or Meshmixer before slicing in Cura, PrusaSlicer, or Simplify3D.

- Run an auto-repair only after saving your master file—external tools may alter topology; inspect before committing.

- For split builds, name shells clearly in FormZ so multi-part STLs are easy to track in your slicer project.

When speed and predictability trump metadata, STL is the default. Keep your focus on manifold geometry, unit integrity, and facet tolerances aligned to your process capability, and your prints will be both clean and repeatable.

3MF: modern, compact, and metadata-rich for AM

3MF was designed to fix what STL omits. It carries explicit units, names, colors, materials, and assemblies in a compact container, making multi-material and multi-part builds more robust. If your slicer and printer support 3MF natively, it streamlines handoffs and reduces operator mistakes caused by scale ambiguity or lost group structure.

Best for

- Printers and slicers that support colors, multiple materials, part grouping, and embedded units

- HP MJF, Ultimaker, Prusa, Bambu, and other ecosystems adopting 3MF

Export steps and critical settings in FormZ

- File → Export → 3MF. Enable embedding of units, colors, and materials when available.

- Keep instances/assemblies as groups to retain relationships in multi-part builds.

- Preserve names and layers for BOM-like grouping in your slicer; map FormZ layers to meaningful process names.

- If using textures, ensure UVs are valid and texture assets are saved relative to the 3MF package (some implementations embed; others reference).

Why choose 3MF over STL

- Smaller files with explicit units; fewer scale errors and less file bloat.

- Maintains color-per-face and texture references for multi-material printing.

- Retains part hierarchies so orientation, duplication, and bed layouts are easier to manage.

Pre-export modeling checklist

- Run the same watertight checks as STL; fix non-manifold issues before export.

- Verify UVs if using textures; avoid overlapping UVs for texture-critical parts.

- Consolidate materials to a minimal, printer-supported set to prevent unexpected down-conversions.

Pitfalls and prevention

- Legacy slicers may down-convert 3MF to STL—confirm full 3MF support so you don’t lose materials or units.

- Complex texture maps can bloat files and slow slicing; consider texture baking and cap resolution to your printer’s effective DPI.

- If your workflow includes cloud print services, test whether metadata survives upload/download cycles.

Downstream guidance

- For assemblies, maintain consistent coordinate frames in FormZ so placement in the slicer mirrors your design intent.

- When mixing rigid and flexible materials, color-code by material in FormZ and propagate these tags into the 3MF to minimize operator error.

- Archive the 3MF alongside a readme stating units, intended materials, and orientation notes; 3MF is excellent for long-lived, production-grade handoffs.

If your ecosystem supports it, 3MF is a forward-looking default for additive parts. Its compactness, embedded units, and material support close the gaps that commonly bite STL users, especially in professional environments with multiple operators and machines.

OBJ (+MTL/Textures): for color, multi-material, and high-fidelity meshes

OBJ remains a versatile mesh format with broad support in visualization tools and many color-capable printers. Unlike STL, OBJ references materials via an MTL file and can use texture maps and per-vertex attributes. For appearance models, dyed MJF parts, and legacy full-color systems, a careful OBJ export from FormZ preserves visual intent without compromising geometry.

Best for

- Full-color prints (e.g., PolyJet, older CJP), dyed MJF parts, and appearance models

- Preserving UVs, vertex color, and smoothing groups

Export steps and critical settings in FormZ

- File → Export → OBJ. Enable MTL export; ensure texture paths are relative and all assets are included.

- Set a smoothing angle that retains sharp edges—typical 20–40° preserves creases without faceting cylinders.

- Units: confirm millimeters; check axis orientation and swap Y/Z if required by your target system.

- Triangulate n-gons if your downstream tool requires it; many printers prefer triangle meshes.

Pre-export modeling checklist

- Ensure manifold geometry just as you would for STL; close any open borders.

- Validate UV layout; avoid overlapping UVs for texture-dependent parts to prevent color bleeding.

- Consolidate duplicate materials and remove unused textures to streamline the MTL.

For a branding mockup with multi-color graphics, bake high-resolution logos into a single texture per material set, keeping the effective pixel density near the printer’s true color resolution. As an example, if the process achieves 600 dpi on the part’s surface, a 2048×2048 map may be more than adequate for a 60×60 mm face; higher resolutions won’t increase printed fidelity but will tax memory.

Pitfalls and prevention

- Missing textures due to absolute paths; use relative paths and keep a clean export folder containing all bitmaps.

- Excessive texture resolution increases memory footprint and slows slicing; cap at the printer’s effective DPI.

- Over-smoothing can blur design intent. Use a cautious smoothing angle and add hard edges where crisp transitions are functionally important.

Downstream guidance

- Some color-print workflows still prefer VRML 2.0/WRL. Use OBJ unless your printer explicitly requests VRML.

- Run a quick render preview in a neutral tool to verify UVs and materials look correct before handing off to production.

- When dyeing MJF parts, export per-face colors to guide post-process masking and stencils, even if the printer ignores textures.

OBJ’s balance of image-based detail and simple geometry makes it a durable choice for visual fidelity. With disciplined asset packing and smoothing groups tuned to your design, you can deliver color-accurate, print-ready meshes from FormZ with minimal surprises.

STEP (AP214/AP242): solid-accurate CAD for CNC, machining, and fabrication

When downstream operations require exact surfaces and edges, STEP is the right handshake. It carries NURBS surfaces and solids, preserving analytic geometry like planes, cylinders, and cones that CAM systems exploit for toolpath intelligence. From milling and turning to sheet metal and metrology, STEP from FormZ provides a robust bridge into parametric CAD and CAM.

Best for

- Hand-off to CAM, machining, sheet metal, and parametric CAD systems

- Maintaining analytic geometry and precise edges

Export steps and critical settings in FormZ

- File → Export → STEP. Export as solids, not facetted surfaces.

- Sew surfaces in FormZ before export; confirm shells close within your target tolerance.

- Choose AP214 or AP242 to preserve colors and layers where supported; AP242 is broadly adopted and modern.

- Units: set mm or inch explicitly to match the recipient’s CAM setup.

Pre-export modeling checklist

- Heal tolerances: stitch and merge edges; remove tiny faces below CAM tolerance (e.g., below 0.05 mm may be noise).

- Simplify fillets and chamfers if downstream tooling will replace or parameterize them. Overly ornate blends can be heavy and fragile.

- Eliminate sliver surfaces and degenerate trims; these often break sew operations in receiving systems.

As a practical approach, choose a sewing tolerance aligned with manufacturing reality—on milled aluminum parts, a 0.01–0.02 mm tolerance is often sufficient; for large welded fabrications, 0.1 mm or more may be acceptable. If you’ve imported mesh-based features as reference, remodel critical surfaces as true NURBS so that toolpaths can reference perfect cylinders and planes rather than approximated triangles.

Pitfalls and prevention

- Gaps between surfaces lead to open shells; apply a realistic sewing tolerance and resolve mismatched edges.

- Overly complex blends and imported meshes don’t translate cleanly—avoid mesh-to-STEP unless necessary, and remodel where precision matters.

- Hidden unit mismatches cause awkward scale issues in CAM. Embed units and communicate them in your transmittal.

Downstream guidance

- If a vendor requests IGES or SAT, export those from the same solid model, but prioritize STEP for best interoperability.

- Keep face colors to indicate manufacturing operations (e.g., stock-to-leave or masked surfaces) when the receiving system honors AP214/AP242 attributes.

- Send a parasolid or native file only when STEP is unsuitable; a neutral, well-sewn STEP reduces vendor lock-in.

STEP shines when you need fidelity and editability in the receiving environment. It transmits intent: planar faces stay planar, cylinders are true, and precise edges remain interrogable by CAM strategies like rest milling or hole recognition.

DXF/DWG: 2D profiles for laser, waterjet, plasma, and routing

Flat processes run on clarity. DXF and DWG remain the lingua franca for cutting profiles, engraving, and shop documentation. The challenge is not just exporting curves, but delivering clean topology that drives smooth toolpaths: continuous contours, correct layer semantics, and geometry placed precisely in model-space at 1:1.

Best for

- Flat pattern cutting, engraving, and CNC profiling

- Shop-floor readability and broad CAM compatibility

Export steps and critical settings in FormZ

- Derive 2D from 3D: create true-planar sections or flattened layouts before export.

- Curves: prefer arcs and splines over segmented polylines; set chord tolerance appropriate to cutter kerf (e.g., ≤10% of kerf).

- Layers: separate cut/etch/mark operations by layer and color; confirm line weights per vendor specification.

- Units: match the shop’s requirement; place all geometry at Z = 0 in model space.

Pre-export modeling checklist

- Close polylines for interior pockets; remove duplicates and overlapping edges at shared boundaries.

- Convert text to outlines if needed; purge blocks and symbols not required for cutting.

- Verify tangent continuity across arcs and splines so machines don’t stutter on G1 segments.

Consider a nested sheet-metal bracket: project its faces for outer profiles, unfold bends for flat patterns, and assign layers such as CUT_OUTER, CUT_INNER, and ETCH_BEND. With kerf around 0.2 mm on a fiber laser, a spline-to-arc approximation chord height of 0.02–0.05 mm yields a smooth edge without overwhelming the controller. Shops appreciate clarity—put bend lines and notes on a non-cut layer with distinct color.

Pitfalls and prevention

- Hidden scaling from page-space exports—always export model-space at 1:1.

- Exploded splines into many segments can lead to jerky toolpaths; retain native arcs and splines where possible.

- Unjoined micro-gaps cause lost profiles; run a join/close operation and test continuous toolpath generation in a viewer.

Downstream guidance

- Send a small test panel to validate kerf, lead-ins, and bend allowances before full production.

- Provide a layer legend and units note with your file to eliminate ambiguity at the machine.

- For routers, dogbone or T-bone interior corners in FormZ to accommodate cutter radius—don’t leave this to chance on the shop floor.

Clean profiles are the difference between a smooth run and a scrapped sheet. With continuous curves, coherent layers, and kerf-aware chord tolerances, your DXF/DWG exports from FormZ become production assets, not debugging exercises.

Brief conclusion

Choose STL for fast, reliable prints; 3MF for unit-safe, multi-material builds; OBJ for color and texture fidelity; STEP for precise, machinable solids; and DXF/DWG for 2D cutting. Across all of them, lock units early, set tolerances to match the manufacturing process, validate manifoldness and topology, and dry-run your files in a viewer or slicer before committing to production. With those habits in FormZ, you elevate data integrity and get parts that look and measure exactly as intended.