Your Cart is Empty

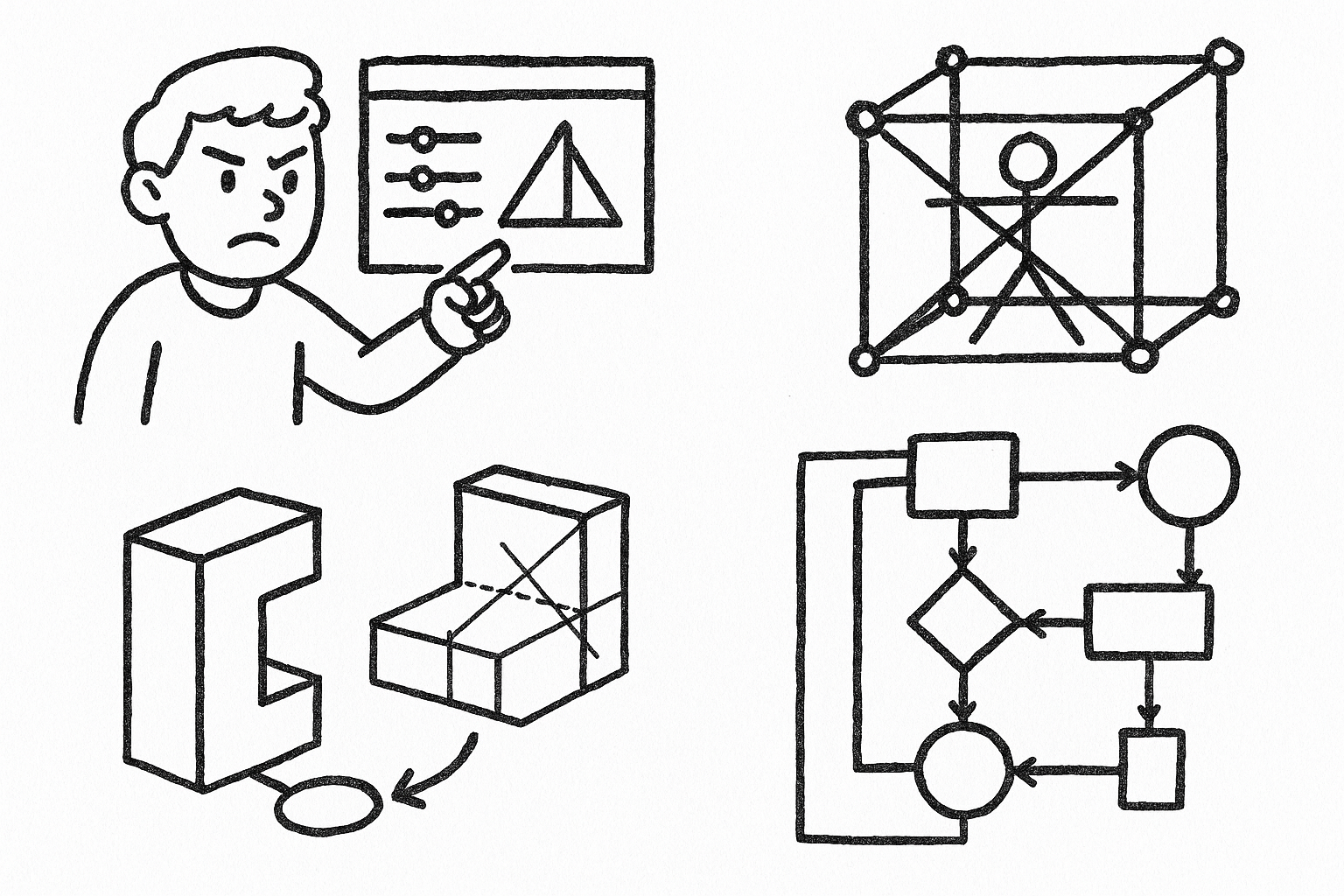

Disciplined parametric strategy is the fastest route to variant-rich, change-resilient models because it turns edits into predictable, low-friction operations. Here, “tricks” means concrete techniques that reduce rebuild fragility, accelerate edits, and enable automation for power users building configurable products, complex assemblies, or computational design workflows.

Build a master parameter architecture before modeling

Start by designing your parameters with the same rigor you’d give to geometry. A robust parameter plan prevents inconsistent assumptions, enforces unit safety, and makes downstream configuration predictable. The outcome is a model that accepts new inputs without threatening stability or performance.

Define a single source of truth

Consolidate all governing variables into a clear, centrally managed layer. This is your model’s brain. Embrace a structured scheme so anyone can scan the parameter list and infer intent immediately.

- Create global/named parameters for dimensions, materials, tolerances, manufacturing allowances, and environmental constraints. Maintain a single source of truth rather than scattering local overrides across sketches.

- Use consistent naming conventions. A reliable pattern is to prefix by domain:

-

g_for global (e.g.,g_length,g_width,g_temp_max) -

p_for part-scoped (e.g.,p_wall_thk) -

a_for assembly-scoped (e.g.,a_mount_pitch) -

m_for manufacturing (e.g.,m_bend_allow,m_tool_rad)

-

- Group by function and units. Keep length, angle, count, and material parameters in distinct clusters. Use descriptions to document rationale and permissible ranges.

Encode design logic with equations

Don’t leave feasibility to luck. Bake the rules of your product family into equations that produce only valid geometry. Enforce physical constraints, fit rules, and minimums using unit-safe expressions.

- Use min/max clamps to protect against impossible inputs:

p_rib_thk = max(1.5 mm, 0.6 * p_wall_thk) - Express discrete lookups with piecewise mappings or tables:

// Sheet gauge to thickness (mm) p_thk = gauge_to_thk[g_gauge] // e.g., 16 → 1.52 mm p_wall_thk = max(p_thk, 2.0 mm) - Isolate geometric rules from presentation. For example, let

g_clearance_fnproduce a numeric clearance from fit class and material, then consume it in features where needed.

Derive everything that can be derived. Secondary parameters reduce duplication and keep edits coherent. If a_mount_pitch moves, the count in a pattern, the web width, and the hole edge distances should all update without manual touch.

Externalize for scale

When you cross from “a few” size variants into hundreds, externalize. Design tables and spreadsheets are excellent for managing families, metadata, and downstream integration.

- Link parameters to a design table keyed by nominal size or SKU. Keep dimensions, material codes, surface finish, and tolerance classes in the same table that drives variants.

- Map parameters to model properties like

SKU,Mass,Cost, andFinish. A change ing_lengthshould propagate to cost rollups and drawing title blocks automatically. - Keep one file authoritative for each domain: engineering values in the model, BOM metadata in a PLM/ERP export, and human-readable descriptions in a spreadsheet.

Guardrails and performance

Guardrails prevent bad inputs and make errors discoverable. Performance-aware dependency planning keeps rebuilds fast.

- Add validity checks with Boolean flags. Example:

Coupleis_valid_clearance = (p_hole_dia >= p_bolt_dia + 2*g_clearance) is_valid_thk = (p_wall_thk >= m_tool_rad * 2) is_valid = is_valid_clearance AND is_valid_thkis_validto warnings or suppression states that alert the user before geometry fails. - Avoid overconstraining. Prefer single-direction dependency chains over webs of cross-links; it reduces solve time and eliminates circular references.

- Keep live equations lightweight; precompute lookups rather than embedding long conditional chains in feature dialogs.

Use skeleton/top‑down modeling to drive parts and assemblies

Top‑down control aligns interfaces across parts and avoids alignment-by-accident. A skeleton holds the product’s spatial intent; parts consume only the stable references they need. The result is change‑resilient models that scale in complexity without collapsing.

Establish a master reference model

Build a skeleton model that captures the core framework: high-level sketches, key datums, envelope solids, mating surfaces, and paths. The skeleton owns mounting grids, overall volumes, symmetry planes, and routing lines.

- Publish only stable references: base planes, axes, coordinate systems, named points, path curves, and interface surfaces. Avoid exposing fragile edges or filleted faces.

- Express dissimilarity by layering: one layer for packaging envelopes, another for structural paths, and a third for interface patches.

- Keep versioned milestones. When a major interface is agreed, freeze a copy or lock parameters that should not drift.

Derive or link geometry into child parts

Child parts should reference the skeleton directly. Lateral references between siblings cause hidden cycles and diagnosis nightmares.

- Drive critical interfaces—mount hole centers, gasket landings, alignment pins—from the skeleton’s datums and sketches.

- Forbid in‑context references between sibling parts. If a part needs another’s shape, publish a proxy datum or interface surface via the skeleton instead.

- Lock or break links at release. Freeze geometry references for released parts while keeping the master flexible for unreleased areas.

Control update strategy

Order matters. Update from coarse to fine. Keep delicate features late in the tree to reduce topology churn.

- Build core volumes first: base extrusions, revolves, thicken surfaces.

- Apply patterns, shells, drafts, and fillets late. Late filleting improves topological stability when upstream dimensions shift.

- Use simplified/suppressed states for large assemblies. Drive preview and configuration checks with lightweight reps; rebuild full detail only when needed.

Change-resilience

Separate intent from manufacture. Keep manufacturable features local to the part, while the skeleton retains design intent.

- Localize CAM-driven features—tabs, dogbones, injection gating bosses—to parts. Do not imprint manufacturing artifacts into the skeleton.

- Maintain a strict no orphan feature rule. Every sketch plane, axis, and path should trace to a skeleton datum or a named, published reference. Orphaned picks are future failures.

Eliminate fragile references with datum‑first, intent‑based selections

Most rebuild failures come from topological changes—an edge index disappears, a face splits, a fillet merges. The antidote is to anchor features to stable abstractions: datums and intent references, not transient faces.

Prefer datums over faces/edges

- Use planes, axes, midplanes, coordinate systems, and construction surfaces as primary anchors. They are stable even when geometry morphs.

- Derive midplanes from bounding boxes to maintain symmetry automatically. Employ silhouette axes for cylindrical or revolved alignment independent of edge identities.

- Drive offsets from sketch geometry or construction surfaces rather than filleted faces that may vanish or reorder.

Use intent references where supported

- Select “cylindrical axis” or “hole center” feature intent rather than a specific edge. Intent remains valid if the cylinder’s tessellation or edge count changes.

- Pick the “midpoint of edge set” or “tangent to surface group” instead of an individual element. Group-level intent is less likely to break when faces split.

- Define named selections for groups of faces or edges (e.g., “outer_fillet_chain”). If topology changes, reassign the selection once and all dependent features follow.

Feature ordering and stability

The sequence of features determines how much you pay for change. Model the essence first, decorate later.

- Create core volumes before derived geometry. Aim for one primary solid per logical body before shelling, drafting, or filleting.

- Avoid attaching sketches to patterned instances. Instead, reference the seed or a datum positioned by the pattern origin.

- Replace direct face picks with named selections or published geometry referenced by name, not index.

Diagnostics and cleanup

Invest in traceability and tooling for fast repairs when topology shifts are unavoidable.

- Name critical features and datums. Use clear conventions like

PLN_SYM,AX_MAIN,CSYS_MFG. - Audit the parent/child graph periodically. Eliminate hidden cross-dependencies and rebuild hotspots.

- When geometry changes invalidate references, retarget to datums or named selections rather than regenerating edge picks.

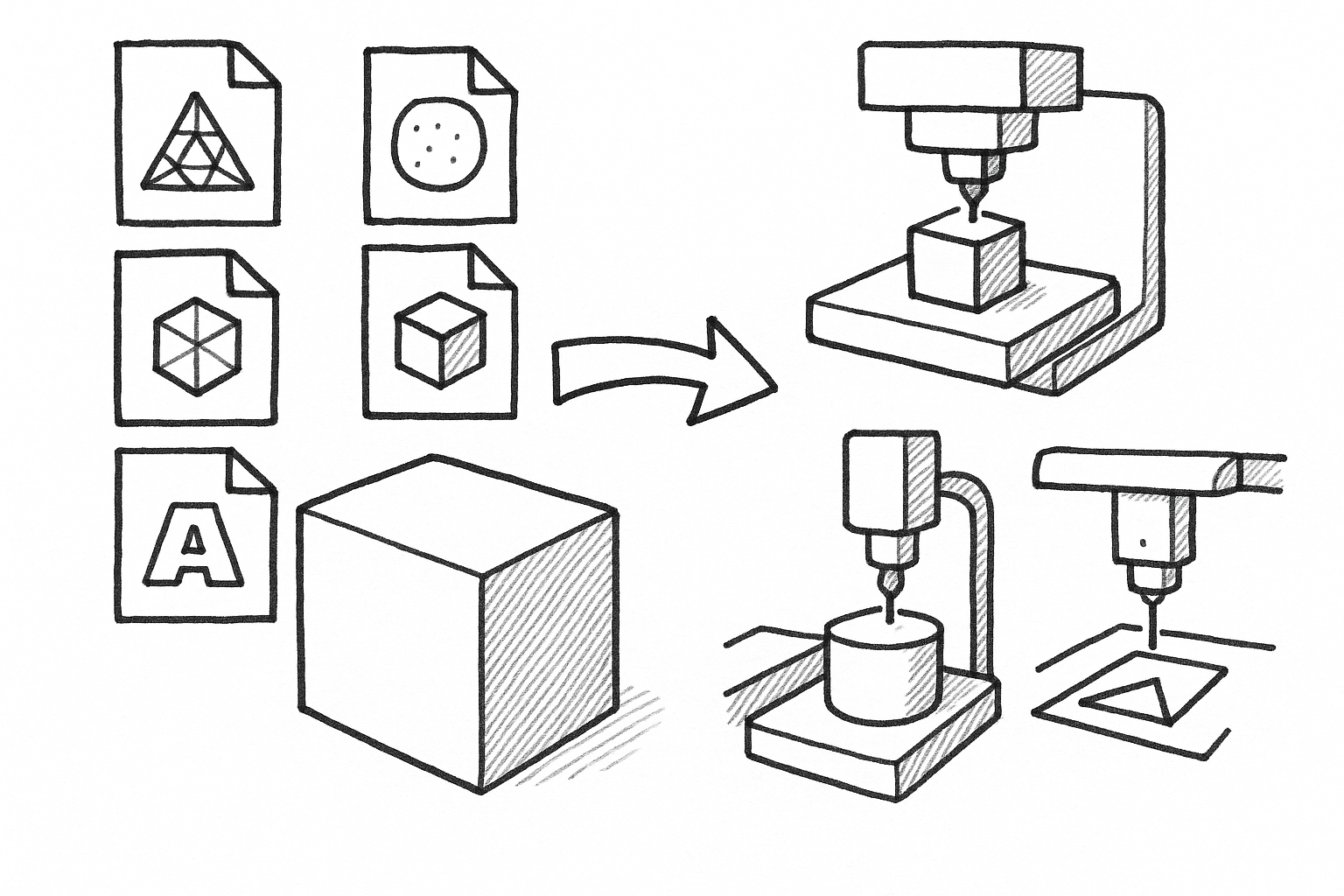

Master configurations/variants with rule‑based suppression and property mapping

As your product line grows, configuration logic deserves first-class design. Rules should govern what combinations are allowed, what features appear, and what metadata accompanies each variant. The goal is to press a single button and get a coherent, manufacturable instance: geometry, properties, and documentation in sync.

Structure variant logic

- Use configurations/family tables/design variants to control dimensions, materials, and feature suppression. Each variant should be defined by inputs, not by manual toggles.

- Encode compatibility with if/then logic:

if g_length >= 800 mm then p_add_mid_support = true if p_material == "Al6061" then m_min_fillet = 1.0 mm else m_min_fillet = 0.8 mm if opt_handle and not opt_cover then is_valid = false - Separate visual options (logos, textures) from manufacturing options (threads, tap depths, inserts) to avoid accidental shop-floor errors.

Table-driven control

Tables are a transparent, auditable place to encode variants. Use them to drive both geometry and metadata.

- Key design tables by SKU or size code. Drive instance counts, pattern spacing, optional features, and thicknesses directly from rows.

- Auto-populate metadata like mass, cost, supplier codes, and drawing notes. Bind drawing note tokens to properties so they always match the variant.

- Keep derived metrics in the table too: footprint area, packaging volume, center of gravity. These inform downstream logistics and CPQ without extra calculation.

Assembly-level coherence

The top-level variant should propagate options to subassemblies and parts deterministically. That means linked parameters and controlled suppression.

- Propagate top-level options via linked parameters (e.g.,

a_has_cover → p_has_coverin each affected part). Avoid per-part switches that drift out of sync. - Maintain lightweight or simplified representations for large assemblies. Use them for configurator previews and interference checks; switch to full detail for release.

- Keep visual configurations distinct from manufacturing ones. A glossy render variant should never change thread callouts or tolerances.

Quality gates

Validate every configuration early and often to prevent invalid combinations from reaching downstream systems.

- Run quick rebuild sweeps across the configuration matrix to catch solver failures.

- Perform automated interference checks where applicable, at least for high-risk zones. Tag results back to configuration IDs.

- Use derived “check” parameters for DFM sanity:

Block invalid variants in the table withchk_clear = min(all_clearances) // >= g_min_clear chk_draft_ok = (min(all_draft_angles) >= m_min_draft) chk_print_time = estimate_print_time(g_layer_h, p_vol)is_valid = chk_clear >= g_min_clear AND chk_draft_ok.

Extend parametrics with rule engines and scripting

Native parameters are powerful, but code turns your model into a living system. Rules respond to edits, generate repetitive geometry, and integrate with external data. The aim is not fancy code—it’s leverage: fewer manual steps with higher reliability.

Turn parameters into behaviors

- Create event-driven rules that react to parameter edits. For example:

This keeps slot counts valid, suppresses when unnecessary, and updates labels without user intervention.onChange(g_length): p_num_slots = clamp(round(g_length / p_slot_pitch), 2, 12) suppress("slot_array", p_num_slots == 0) set("label_text", format("{0}mm", g_length)) - Generate geometry programmatically for repetitive structures. Grids, lattices, perforations, gusset arrays, and rib networks are safer and faster to create via loops than manual patterns.

- Express constraints as functions:

safe_fillet(r, thk) = min(r, 0.45*thk)and apply them consistently across features.

Data I/O and automation

Integrated data flows remove drudgery and eliminate transcription errors. Your models should speak CSV/JSON as easily as they speak geometry.

- Read/write tabular data to sync with CPQ/PLM. Import new SKUs, update costs, and push back mass properties after rebuild.

- Batch-generate families and drawings. Script the creation of STEP for manufacturing, STL for printing, DXF for laser, and PDFs for release in one pass.

- Run parameter sweeps for optimization and tolerance studies. Log KPIs—mass, cost, modal frequencies, print time—to a results file keyed by variant.

Robustness and testing

Treat your parametric system like software: modular utilities, regression tests, and clear interfaces.

- Centralize utility functions for rounding, unit conversion, clamps, and lookups:

mm(x_in) = x_in * 25.4 clamp(x, lo, hi) = max(lo, min(x, hi)) - Add regression tests that iterate through representative variants and assert no rebuild errors, no suppressed critical features, and minimum clearances satisfied.

- Version your rule scripts. Keep change logs so you can correlate model behavior with rule updates.

Performance hygiene

Parametric power can be squandered by noisy updates and unnecessary recomputation. Keep it lean.

- Minimize inter-part event storms. Batch updates at the top assembly and push changes once per cycle.

- Cache expensive computations—like tessellations, pathfinding for cable routes, or mass property calculations—until the user stops dragging sliders or commits a change.

- Prefer incremental rebuilds. Suppress visualization-heavy features (complex patterns, high-density fillets) during exploration; resume them for finalize/export.

Practical examples that tie it together

Suppose you’re developing a configurable enclosure family. A concise parameter plan and skeletal control can make the difference between one-hour and one-minute changes.

- Master parameters:

g_length,g_width,g_height,g_ip_rating,g_mount_pattern,m_bend_allow,m_k_factor. Add a materials mapmat = {"Al5052": {...}, "SS304": {...}}with density, min bend radius, and cost per kg. - Equations:

p_wall_thk = max(mat[g_material].min_thk, 2.0 mm),p_corner_rad = max(1.2*m_tool_rad, 0.5*p_wall_thk),p_fastener = if g_ip_rating >= 65 then "M5" else "M4". - Skeleton: planes for bottom/top, midplanes for all axes, a 3D sketch that defines hinge axis and latch keep-out, and a construction surface for gasket land.

- Intent references: hole patterns driven by a coordinate system and mount grid sketch; fillets applied last with radii derived from

p_corner_rad; shell feature late to handle internal volumes with fewer face merges. - Configuration table keyed by SKU:

- Rows: size codes (200×120×80, 300×180×90), options (window, handle, EMC gasket), material.

- Columns drive:

g_length,g_width,g_height, suppression offeat_window,feat_handle, and selection of gasket profile. - Properties populated:

Mass,PaintArea,Cost,IP_Rating, and drawing notes like “Add captive screws for lid.”

- Rules and automation: when

g_lengthexceeds a threshold, auto-add a mid-rib and split gasket into two segments; export STEP, DXF flat patterns, and a PDF BOM per variant in a batch script. - Quality gates: computed

chk_gasket_compressstays within ±10%;chk_screw_edgevalidates minimum edge distance; interference check between hinge knuckles and gasket lip must be zero.

Or consider a lattice-heavy additive component. Parameters for cell size, strut diameter, and skin offset can bind to a rule that maintains target porosity and stiffness. A script generates lattice zones from a set of bounding surfaces, caches intermediate meshes during slider changes, and only recomputes iso-surfaces on commit. The skeleton supplies load-path axes and attachment surfaces, while intent references keep constraints tied to midplanes rather than fillet edges on the mounting bosses. Variants adjust lattice density and skin thickness, while quality checks track minimum strut diameter for printability and overhang angles for supportless regions. Throughout, datum‑first modeling and rule‑based suppression ensure that each variant stays valid and fast to rebuild.

Common failure modes and how these practices prevent them

- Edge ID churn breaks fillets and chamfers. Fix: use fillet late, reference named edge sets or tangent selections, and prefer intent-based picks.

- Feature graphs become cyclic and slow. Fix: enforce a monotonic dependency flow (skeleton → parts → features), and consolidate equations in the parameter layer, not scattered in sketches.

- Configuration sprawl causes mismatched drawings. Fix: table-driven property mapping and automated export pipelines that regenerate drawings per variant.

- Manufacturing updates invalidate model intent. Fix: keep manufacturing allowances and bend data in

m_*parameters, derive model features from them, and version them independently of design geometry.

Process adoption and team templates

Discipline scales when everyone shares the same mental model. Package these practices into templates and checklists so new projects begin with strong defaults:

- Project starter with predefined parameter groups (

g_*,p_*,a_*,m_*), skeleton datums, and a sample design table. - Rule library of common building blocks: clamp/minmax, edge distance checks, hole pattern generators, export batch scripts.

- Naming and publish policies: what references are allowed to be public, how to mark intent datums, and how to deprecate legacy ones.

- Review checklist: parameter audit, skeleton completeness, orphan feature scan, configuration sweep, and regression test run.

Conclusion

The fastest models are the ones that change cleanly: define master parameter architecture, drive geometry from a skeleton/top‑down modeling approach, anchor features to datums and intent-based selections, govern variants with rule‑based suppression and property mapping, and automate with rule engines and scripting. Start small: retrofit one existing project with these five techniques, then standardize them into your team’s template. The payoff is immediate—edits become inputs rather than rebuild adventures, and scale becomes a feature of your workflow, not a liability.