Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

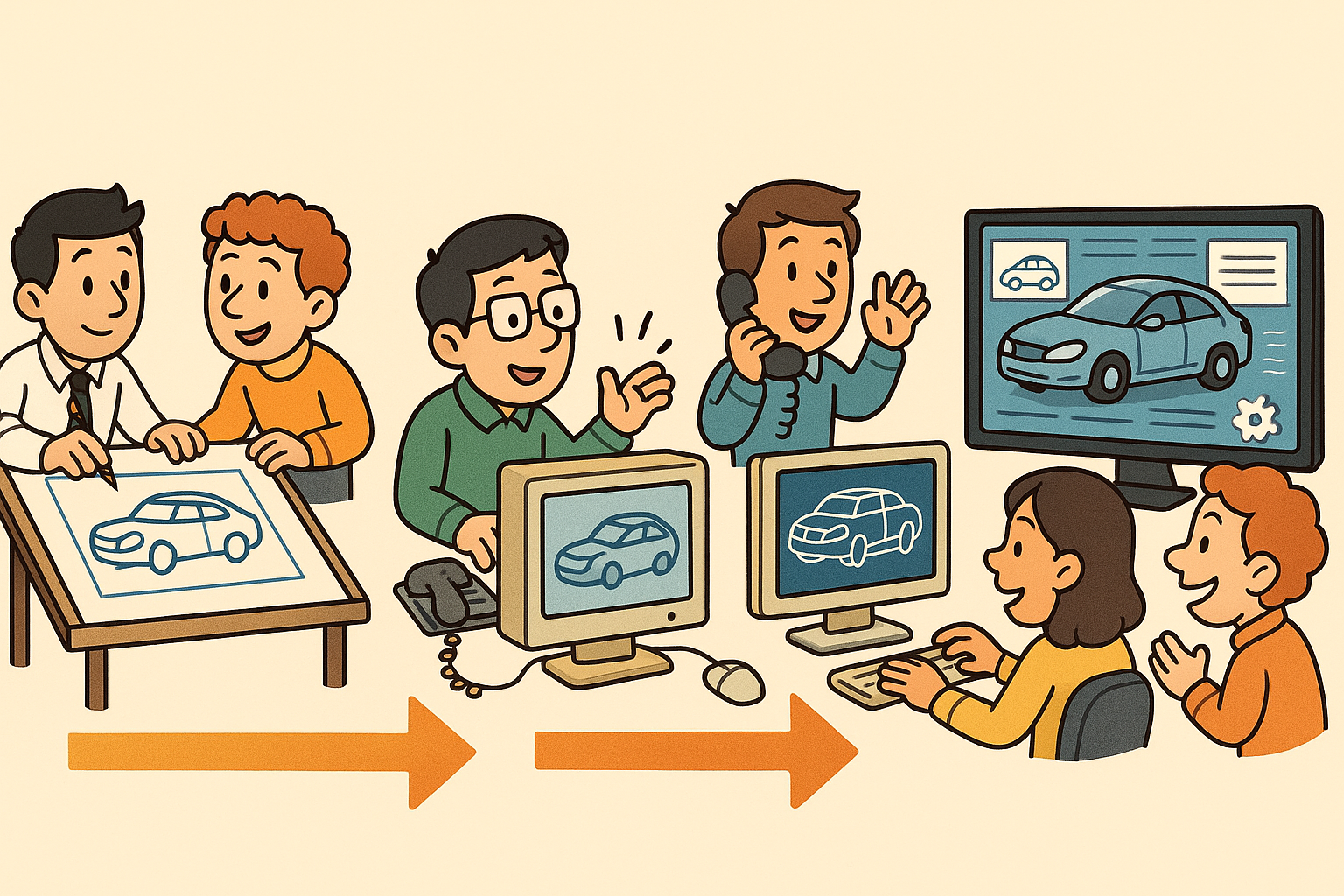

Design Software History: The Evolution of Product Lifecycle Management: From Early Design Coordination to Integrated Collaborative Systems

May 21, 2025 7 min read

Origins and Early Development

The evolution of Product Lifecycle Management (PLM) began with the need to address persistent design coordination issues and the growing complexity of engineering projects in the mid-20th century. Early design teams often experienced significant difficulties in controlling revisions, sharing technical data, and maintaining consistency across multiple design stages. Organizations first encountered problems such as overlapping design efforts, miscommunication among departments, and the lack of unified tools for handling ever-changing versions of product designs. Early digital efforts were characterized by isolated software tools designed merely to document and store data. As various industries sought better control over their design processes, the notion of integrating these disparate activities into a cohesive system became increasingly appealing. The drive to establish improved version control and collaborative design practices resulted in the creation of specialized systems that laid the groundwork for modern PLM.

Defining PLM and Its Contributors

Designers and engineers gradually recognized that solving their coordination challenges required more than the isolated use of computer-aided design (CAD) tools or draft management systems. Instead, they needed an integrated approach that embraced a holistic view of the product process lifecycle from the concept stage to manufacturing, maintenance, and disposal. Early adopters focused on:

- Centralizing design documentation and engineering data

- Streamlining version control mechanisms

- Establishing collaborative protocols among multi-disciplinary teams

- Ensuring that every change in the design cycle was traceable

Early Innovations and the Birth of PLM

The period saw significant experimentation with software that integrated multiple aspects of product design, manufacturing, and lifecycle management. Early systems, sometimes developed in-house by major industrial players, were among the first to implement rudimentary principles that would eventually evolve into the complex PLM systems we see today. Pioneering innovators explored the integration of drafting, assembly design, and product documentation into singular workflows. These projects were often supported by the engineering departments of aerospace, automotive, and heavy manufacturing companies, which recognized the need for robust design methodologies. Many of these developments, while primitive by today’s standards, introduced the concept of a product information model—a digital representation of the product that was continuously updated, reviewed, and refined. The contributions of early systems and technical experiments set the stage for modern PLM by establishing a framework for data integrity, traceability, and collaboration that continues to influence product design across industries.

Evolution and Technological Advancements

Over time, technology advanced beyond rudimentary data repositories to deliver fully integrated PLM systems capable of handling the comprehensive demands of modern design environments. The transition was epitomized by the integration of CAD, CAM, and advanced engineering data, which transformed the landscape of design software. Early data management tools that handled basic file storage and communication gradually evolved into systems that synchronized detailed CAD models with manufacturing instructions, simulation software, and documentation. This evolution was driven by rapid advances in hardware, software algorithms, and networked communication technology during the late 20th century. Secondly, the adoption of relational databases and improved networking capabilities provided a robust foundation for PLM systems, enabling them to handle increasingly complex data sets reliably. With enhanced hardware and data management tools, design teams could now collaborate in real time, reducing errors and streamlining the design-to-production cycle—an evolution that marked a turning point in the history of design software.

Integration of CAD, CAM, and Engineering Data

The early 1980s witnessed a monumental shift as companies began linking both computer-aided design (CAD) and computer-aided manufacturing (CAM) software to a single integrated platform. This integration empowered designers and engineers with synchronized views of product designs and manufacturing processes, ensuring consistency across design changes and production specifications. Key elements of this integration included:

- Seamless data exchange between design and production departments

- Real-time updates to design modifications reflected immediately in production planning

- Enhanced interoperability between previously isolated systems

- Verification of design integrity through integrated simulation and testing modules

Interface Design Transformations and Usability Improvements

The transformation from command-line interfaces to graphical user interfaces (GUIs) was another significant evolution in PLM software. Initially, design software was primarily operated via text-based systems, which, while powerful in resource-constrained environments, often posed accessibility challenges for less technologically versed users. As interface design evolved, the development of intuitive user interfaces helped bridge the gap between complex engineering tasks and user-friendly operations. Increased automation of routine tasks and improved collaboration features further revolutionized the design process by reducing manual interventions and errors. Notable improvements in usability included:

- The transition to intuitive, visually engaging GUIs

- Automation of data validation and error checking

- Simplified access to complex toolsets through contextual menus and interactive dashboards

- Real-time communication features integrated within the software

Industry Influences, Key Players, and Examples of Success

The growth of PLM software was spurred by influential companies and visionary individuals who recognized the transformative potential of integrated design management systems. Industry leaders from fields such as aerospace, automotive, and heavy manufacturing had substantial influence on shaping the development of these technologies. Driven by intense market competition and the necessity of managing increasingly complex product data, these companies and innovators invested heavily in research and development. Their efforts not only set standards for future PLM systems but also demonstrated how broad integration of digital tools could enhance collaborative design and drive innovation. Through sustained development and iteration, PLM systems evolved from simple documents and data storage solutions to comprehensive platforms that handle every aspect of a product's lifecycle. These advancements not only boosted product quality but also shortened the development cycle, proving critical for organizations that needed to adapt rapidly to market demands.

Key Industry Leaders and Their Contributions

Several major industry players made profound contributions to the evolution of PLM software. Companies such as IBM, Siemens, and Dassault Systèmes became household names in the world of design technology. Their efforts were bolstered by partnerships with prominent research institutions and collaborative ventures with other global engineering giants. Key contributions from these entities included:

- The integration of multidisciplinary design processes into a single platform

- Development of relational database backbones crucial for managing complex product information

- Implementation of network-based collaboration tools that cut across organizational boundaries

- Continuous software updates that aligned evolving market standards with industry best practices

Interplay Between PLM Software and Broader Design Trends

The evolution of PLM software cannot be fully appreciated without an understanding of its interplay with broader trends in modern design and manufacturing. Market pressures, evolving consumer expectations, the rise of globalization, and increasing demands for customized products all accelerated the adoption of sophisticated PLM systems. Designers and engineers were compelled to produce products at a faster pace while maintaining high levels of innovation and quality. This delicate balance between speed and efficacy drove companies to incrementally enhance their PLM platforms. Key aspects of this interplay include:

- Enhanced product quality through better data integration

- Improved collaboration among dispersed and multi-disciplinary teams

- Faster time-to-market enabled by streamlined design processes

- A reduction in production errors through improved change management systems

Conclusion and Future Directions

The historical journey of PLM software is a narrative of continuous innovation and a relentless drive towards enhancing product design and manufacturing processes. From its humble beginnings, as early adopters struggled with version control and collaboration issues, the evolution of PLM has ultimately fostered a comprehensive environment that seamlessly integrates multidimensional data. The transformation from standalone data management tools to sophisticated, integrated platforms underscores innovations in database technologies, interface usability, and cross-functional collaboration. The influence of key industry players and visionary innovators made it possible for PLM systems to evolve in parallel with advancements in computational power and network technology, ultimately revolutionizing the way products are designed, developed, and manufactured. The enduring legacy of PLM is evident in its ability to consistently adapt to changing market demands and technological breakthroughs.

Reflection on the Transformative Impact

The advancement of PLM software has been integral to the evolution of design processes across the globe. Enhanced collaboration between teams, the reduction of lengthy development cycles, and the assurance of product quality are all benefits that have arisen from the adoption of integrated PLM systems. Moreover, these platforms have empowered industries to adopt more agile production strategies and innovative design practices that cater to dynamic global markets. The benefits include:

- Improved collaborative design across international teams

- Reduced time-to-market through streamlined product development cycles

- Greater capacity to integrate emerging technologies into existing design workflows

- Enhanced traceability and accountability in every phase of product development

Looking Ahead: Trends and Future Trajectories

As we look to the future, there is a strong likelihood that the integration of emerging technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) will further streamline and enhance PLM systems. The integration of these technologies is expected to usher in an era of even greater automation, predictive analytics, and real-time data processing capabilities that will help designers and manufacturers remain agile in a rapidly evolving landscape. Upcoming trends in PLM include:

- The incorporation of IoT sensors that provide continuous feedback during various product lifecycle stages

- Enhanced decision-making frameworks powered by AI algorithms that optimize design workflows

- Even more intuitive user interfaces created with the help of virtual and augmented reality technologies

- Greater integration with global supply chain networks, enabling end-to-end visibility

Also in Design News

Cinema 4D Tip: Constraint-Based Animation with PSR, Parent, and Aim

December 07, 2025 2 min read

Read More

V-Ray Tip: Proximity Dirt and Wear Masks with VRayDistanceTex

December 07, 2025 2 min read

Read More

AutoCAD Tip: Isolate Objects for Focused, Non-Destructive Editing

December 07, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …