Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Evolution of Design Software in Aerospace: From CAD to AI and Additive Manufacturing

July 14, 2024 4 min read

I. Introduction to Design Software in the Aerospace Industry

The aerospace industry is characterized by its incredibly complex systems, stringent safety requirements, and the necessity for precision. These unique needs have driven the adoption and evolution of design software in this field. Initially, the industry relied heavily on manual drafting and physical prototypes, but the advent of computer-aided design (CAD) in the 1960s and 1970s marked a significant turning point.

Overview of the Aerospace Industry's Unique Needs

The aerospace industry deals with projects that are among the most complex in engineering. These projects require:

- Complexity of aerospace systems: From aircraft to spacecraft, the systems involved are multifaceted and require meticulous planning and design.

- High precision and safety requirements: The margin for error is virtually non-existent, necessitating extremely precise designs and rigorous testing protocols.

- Need for collaboration between various engineering disciplines: Aerospace projects often require the integration of multiple engineering fields, such as mechanical, electrical, and software engineering, necessitating advanced collaboration tools and methodologies.

Initial Adoption of Design Software in Aerospace

In the early days, aerospace engineers relied on manual drafting techniques and the construction of physical prototypes to test their designs. However, the limitations of these methods—time-consuming processes, high costs, and the difficulty in making changes—pushed the industry toward adopting computer-aided design (CAD) software. The transition began in the 1960s and 1970s, setting the stage for more sophisticated tools and methodologies that would come later.

II. Key Milestones in Aerospace Design Software Development

The Advent of CATIA

One of the most significant milestones in the history of aerospace design software is the development of CATIA (Computer Aided Three-dimensional Interactive Application) by Dassault Systèmes in the late 1970s. Originally conceived to meet the internal needs of Dassault Aviation, CATIA quickly gained traction and was adopted by aerospace giants like Boeing and Airbus. The software revolutionized the design of complex aircraft structures and systems, providing tools that allowed for far greater precision and efficiency than previously possible.

Introduction of Advanced Simulation Tools

Another major development was the emergence of advanced simulation tools such as ANSYS and NASTRAN. These tools played a crucial role in finite element analysis (FEA) and computational fluid dynamics (CFD), enabling engineers to conduct detailed stress testing, aerodynamic analyses, and thermal assessments. The introduction of these tools marked a significant leap forward in the ability to simulate real-world conditions and optimize designs accordingly.

Integration of Product Lifecycle Management (PLM) Software

The development of Product Lifecycle Management (PLM) systems like Siemens Teamcenter and PTC Windchill introduced a more holistic approach to managing aerospace projects. PLM software allows for the management of the entire lifecycle of a product, from initial design through to production, maintenance, and decommissioning. This integration is critical for maintaining data integrity, ensuring compliance with regulatory standards, and facilitating collaboration across different teams and disciplines.

III. Impact of Design Software on Aerospace Engineering Processes

Enhanced Collaboration and Data Management

The advent of cloud-based platforms has significantly enhanced collaboration and data management in aerospace engineering. These platforms enable real-time collaboration among various teams, improving data integrity and version control. The ability to work on the same project simultaneously from different locations has broken down geographical barriers and streamlined the engineering process.

Accelerated Innovation Cycles

Design software has drastically reduced the time from concept to prototype. The use of generative design and parametric modeling allows engineers to rapidly explore multiple design alternatives, leading to faster innovation cycles. This acceleration is crucial in an industry where time-to-market can make a significant difference in competitiveness and profitability.

Cost and Resource Efficiency

One of the most substantial benefits of design software is its impact on cost and resource efficiency. The ability to create detailed digital simulations has minimized the need for physical prototypes, leading to significant savings in materials and time. Additionally, digital simulations enable the optimization of manufacturing processes, further reducing waste and improving overall efficiency.

IV. Future Trends and Challenges in Aerospace Design Software

Emergence of Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) into design software is a burgeoning trend with far-reaching implications. AI can be used for predictive maintenance and optimization, potentially identifying issues before they become critical. However, ensuring the reliability and trustworthiness of these systems remains a significant challenge that the industry must address.

Advancements in Additive Manufacturing

Additive manufacturing, or 3D printing, is another area where design software is making a substantial impact. The ability to design and print complex aerospace components offers exciting possibilities but also comes with its own set of challenges. Issues related to material properties and certification need to be overcome to fully realize the potential of this technology.

Sustainability and Environmental Impact

Design software plays a crucial role in the development of more fuel-efficient and eco-friendly aircraft. However, achieving sustainability in aerospace involves navigating regulatory challenges and adhering to industry standards. The use of design software to model and optimize for environmental impact is a critical step in this journey.

In conclusion, the evolution of design software has been instrumental in shaping the aerospace industry. From its early days of manual drafting to the sophisticated tools available today, each milestone has brought about significant advancements in precision, efficiency, and collaboration. As we look to the future, the integration of AI, advancements in additive manufacturing, and a focus on sustainability will continue to drive innovation in this ever-evolving field.

Also in Design News

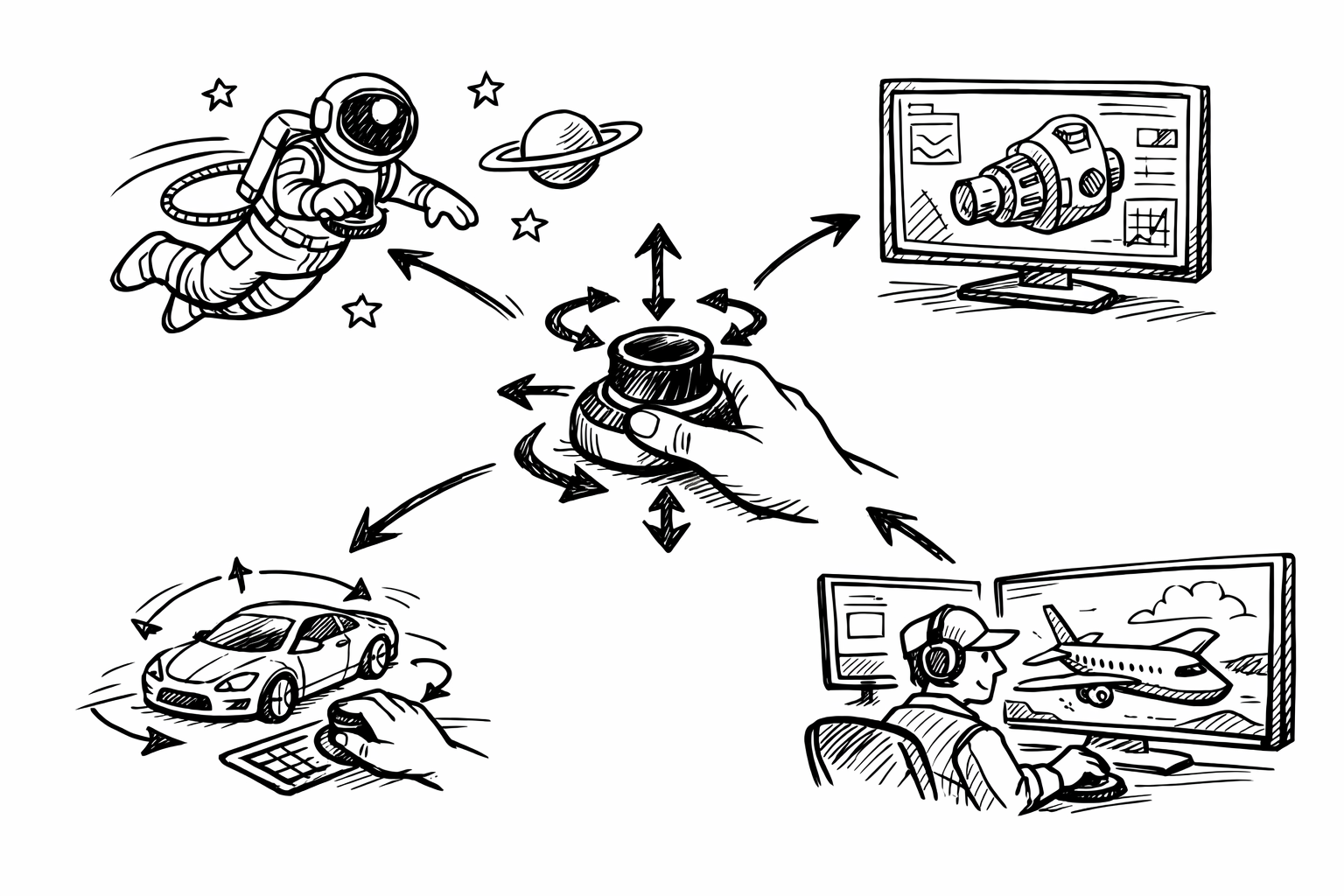

SpaceMouse as Computational Ergonomics: 6DoF Navigation for Faster, More Accurate Simulation Workflows

March 01, 2026 11 min read

Read More

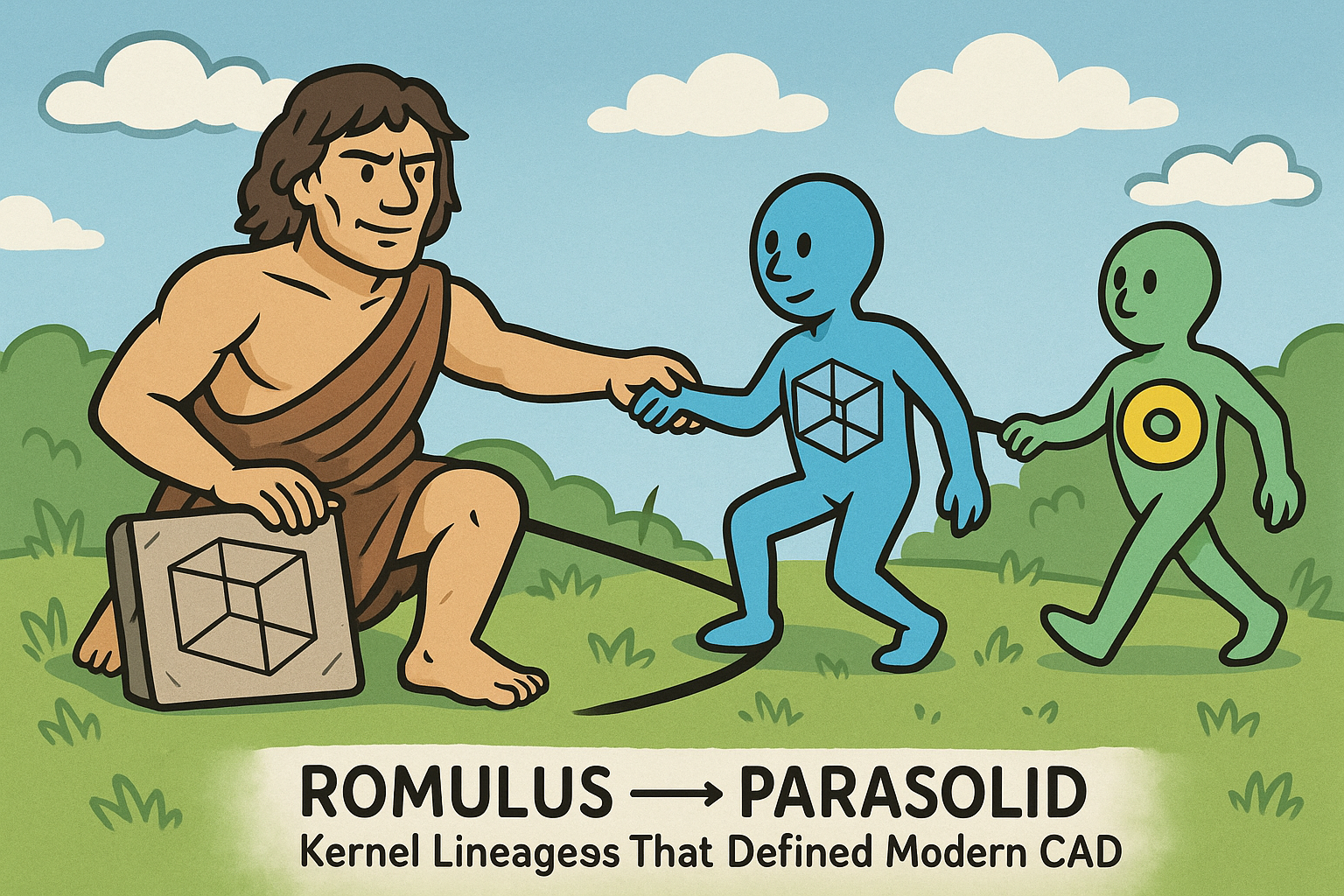

Design Software History: ROMULUS to Parasolid and ACIS: Kernel Lineages That Defined Modern CAD

March 01, 2026 13 min read

Read More

Augmented Assembly: Turning CAD/MBD into Executable XR Work Instructions for the Digital Thread

March 01, 2026 13 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …