Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Advancing Multi-Material 3D Printing through Innovative Design Software Solutions

August 26, 2025 9 min read

Introduction to Multi-Material 3D Printing

Multi-material 3D printing is emerging as a revolutionary technique in additive manufacturing that integrates multiple materials in one build process, resulting in highly functional components that were once impossible to achieve with conventional fabrication methods. In today’s competitive landscape, **multi-material 3D printing** is redefining design and production paradigms by enabling designers and engineers to fuse materials with distinctly different properties, such as stiffness, flexibility, and conductivity, into a single structure. This innovation not only expands the design envelope, allowing for the creation of intricately engineered parts, but also addresses key challenges associated with assembling components from disparate materials in traditional manufacturing contexts. The vast potential of this technology hinges on its capability to produce complex gradients and interfacial regions—areas that benefit from a thoughtful orchestration of material behaviors. This interweaving of diverse materials opens a pathway to previously uncharted territories in industrial applications, where performance and functionality are paramount.

Fundamentals of Multi-Material 3D Printing

At its core, multi-material 3D printing involves the simultaneous deposition of several substances, each with unique thermal, chemical, and mechanical characteristics. Engineers manage these materials through advanced deposition strategies, custom toolpaths, and timed curing processes. The complexity relies on careful calibration that considers factors like material flow rates, thermal expansion coefficients, and the chemical reactivity at bonded interfaces. Design engineers have developed specialized settings and parameter groups that capture these variables, ensuring accurate control across different zones of a printed object. This capability is supported by in-depth material databases and simulation routines that forecast the behavior of interfaces. As a result, designers can fine-tune the properties of transition zones, improving overall part performance while decreasing the probability of failure due to material mismatch.

Significance and Impact in Modern Manufacturing

The impact of multi-material 3D printing on modern manufacturing cannot be overstated. Industries are now harnessing this technology to produce parts that exhibit both aesthetic appeal and engineered performance. In sectors such as aerospace, biomedical, automotive, and consumer electronics, the ability to consolidate functionality into a single part is driving a paradigm shift. This integration not only minimizes assembly requirements but also results in lighter, more efficient, and highly optimized structures. Manufacturers list the following advantages:

- Enhanced design freedom that allows for integrated material properties.

- Reduction in assembly steps, resulting in cost and time savings.

- Improved part performance through bespoke material distributions.

- Opportunities for sustainable production by eliminating unnecessary components.

Software Challenges in Multi-Material 3D Printing

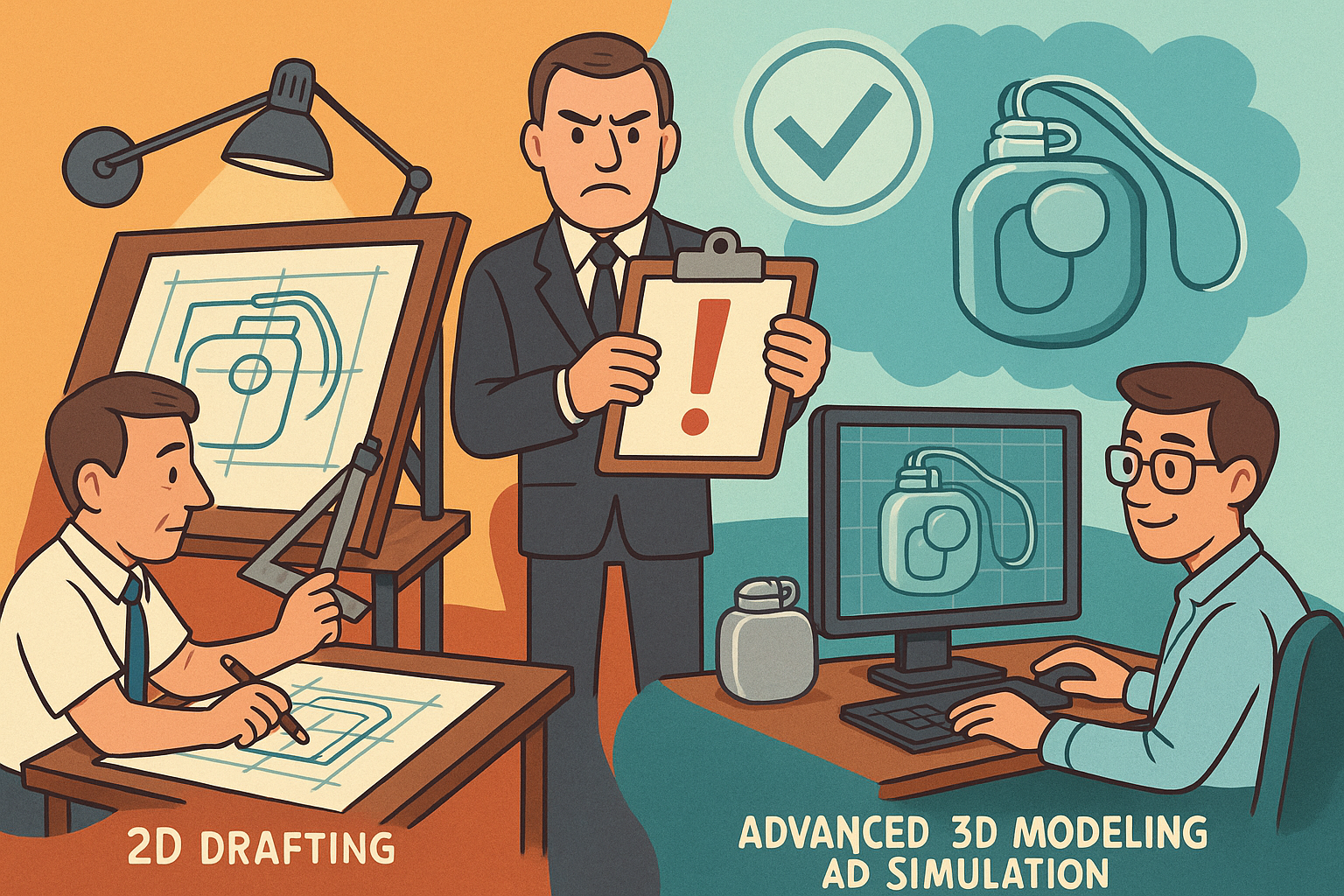

The rapid innovation of multi-material 3D printing brings with it a unique set of software challenges that make the modeling and simulation process exceedingly complex. The necessity to accurately simulate physical interactions between heterogeneous materials puts enormous pressure on design software, which traditionally handles single-material processes. In this evolving ecosystem, algorithms must now account for non-linear material behaviors, including differential thermal expansion, variable bonding strengths, stress concentrations at material boundaries, and complex interfacial phenomena. This additional layer of complexity dictates not only the fidelity of the simulation but also places severe demands on computational resources. As a consequence, traditional CAD/CAE systems are facing steep learning curves when adapted for multi-material simulations.

Challenges in Material Behavior Simulation

Designers must grapple with the intricate task of predicting real-world outcomes that differ from conventional expectations. Specific challenges include:

- Accurately modeling thermal expansion rates, which vary significantly between materials.

- Predicting bond strengths across interfaces, an essential aspect to ensure durability and performance.

- Simulating interfacial stress distribution under various load conditions.

- Ensuring the dynamic response of the final product meets rigorous quality standards.

Compatibility and Integration Challenges

In addition to simulation challenges, there exists a significant struggle with compatibility and integration within established design ecosystems. Many legacy file formats and CAD systems were not built to handle multi-material data, leading to frequent misalignments and inaccuracies. Bridging this gap necessitates a radical overhaul of data structures, communication protocols, and algorithmic approaches. Software teams must often contend with issues stemming from heterogeneous datasets and interpolation errors that become evident during model-to-print transitions. In many cases, ensuring smooth interoperability requires the development of new standards, plug-in architectures, and enhanced error-checking routines that are tailored specifically to multi-material contexts. Such efforts are pivotal for ensuring the reliability of simulations and preserving the design intent through every stage of the production process. Consequently, the design community is continually refining integration protocols and seeking novel software architectures that can seamlessly incorporate multi-material parameters.

Beyond the technical hurdles, the need for real-time process optimization further complicates the development of these systems. With the physical properties of different materials interacting in unpredictable ways, traditional algorithmic approaches often fall short in their ability to adjust printing parameters on the fly. The aspiration for **real-time optimization** becomes an elusive yet crucial requirement as designers seek to maintain high output quality and process efficiency. It is within this challenging environment that the convergence of high-performance computing, adaptive algorithms, and robust simulation models begins to chart the course for future breakthroughs.

Innovative Software Solutions and Advancements

To overcome the multifaceted challenges inherent in multi-material 3D printing, the software industry has responded with a host of innovative solutions aimed at both simulation accuracy and workflow automation. One of the most notable advancements is the development of specialized simulation modules designed to faithfully predict the behavior of disparate materials under varying conditions. These advanced modules integrate finite element analysis (FEA) with cutting-edge machine learning tools to provide real-time feedback and parameter adjustments. This integration enables the prediction and mitigation of potential anomalies, such as unexpected stress concentrations or inadequate material bonding, well before the printing process begins. As a result, designers can confidently push the boundaries of component design while significantly reducing the risk of production errors.

Simulation Modules and AI Integration

The evolution of multi-material simulation software has been largely powered by the infusion of artificial intelligence and machine learning into established simulation protocols. AI algorithms analyze historical data and real-time sensor inputs, adjusting printing parameters dynamically to optimize material behavior during fabrication. This synergy of classical simulation techniques with adaptive AI solutions has widened the analytical framework, enabling:

- Automated error prediction that identifies potential pitfalls before they occur.

- Adaptive tuning of printing parameters to account for minor variances in material properties.

- Enhanced simulation accuracy that allows for more realistic predictions of material interactions.

Automation Tools and Custom Plugins

Complementary to the advanced simulation engines are a suite of automation tools and custom plugins which further streamline the process of transitioning from digital designs to physical prints. These tools are crafted to support wider aspects of the workflow, such as material switching, automated calibration routines, and real-time monitoring. The integration of such tools significantly reduces manual intervention, thereby minimizing errors and accelerating the design cycle. Enhanced user interfaces (UI) play a critical role in this context, offering intuitive dashboards that synthesize vast arrays of complex simulation data into easily digestible formats. These developments ensure that even as the complexity of multi-material printing grows, the user experience remains responsive and accessible. Such automation is a game-changer for operations that rely on rapid prototyping, where efficiency and repeatability are paramount. Ultimately, the combined impact of specialized simulation modules, AI-driven insights, and automation tools is setting a new standard for multi-material additive manufacturing, fostering an environment where innovation can thrive without being hampered by computational or operational constraints.

Further addressing the intricacies of the design-to-production workflow, recent advancements have focused on adaptive user interfaces that respond to the evolving demands of multi-material printing. These interfaces not only highlight simulation results but also incorporate feedback loops from real-time monitoring during production. This dynamic interaction between software and hardware enables designers to achieve optimal print results through continuous, data-driven adjustments. Enhanced visualization tools, integrated material libraries, and context-sensitive tutorials assist users in navigating the challenging landscape of multi-material design. As these user-centric technologies improve, they lower the barrier to entry for new users and facilitate more sophisticated and reliable multi-material manufacturing processes.

Conclusion

In summary, the rapid evolution of multi-material 3D printing has introduced both remarkable opportunities and complex challenges for the design software community. The integration of heterogeneous materials in a single print has amplified the need for advanced simulation tools, robust error prediction algorithms, and adaptive interfaces that together ensure both design fidelity and manufacturing efficiency. Software challenges, such as simulating non-linear material interactions, managing compatibility with legacy CAD systems, and achieving real-time optimization during production, have spurred a wealth of innovation. As the industry pushes further into uncharted territories, it is evident that the traditional roles of design software are expanding to cover complex material science concerns, bridging the digital-physical divide more seamlessly than ever before.

Reflecting on Software Challenges and Advancements

The multifaceted obstacles encountered by designers using multi-material 3D printing have catalyzed a wave of technological breakthroughs within the software domain. By integrating high-performance computational models with machine learning algorithms, developers are steadily closing the gap between simulation and physical reality. Enhanced analytical frameworks now allow simulations to encompass a broader spectrum of variables, thus reducing the occurrence of unforeseen errors during fabrication. Alongside these improvements, new compatibility protocols and data exchange standards are emerging to ensure that all elements of the digital workflow communicate effectively. This holistic approach not only streamlines the process but also fortifies the resilience of the entire production chain. Despite the inherent challenges, the software community has made great strides in addressing issues such as material bonding, thermal inconsistencies, and stress distribution discrepancies through innovative and practical solutions.

Looking forward, the continuous refinement of adaptive algorithms and user-centric design tools promises to further unlock the potential of multi-material 3D printing. The seamless interplay between advanced simulation modules, automation routines, and enhanced user interfaces marks a shift towards more sustainable and efficient manufacturing practices. As these supportive technologies continue to evolve, they lay the groundwork for a future in which digital models can be transformed into extraordinary physical products with unprecedented accuracy and reliability. The integration of these advancements into traditional design platforms paves the way for an era marked by increased innovation, lower material wastage, and more reliable production processes. This evolution underscores the pivotal role that advanced design software plays in harnessing the full capabilities of multi-material additive manufacturing.

Final Thoughts on the Future of Multi-Material 3D Printing Software

The continuous evolution of design software is dismantling long-standing barriers between digital conceptualization and tangible product realization. Today’s tools are no longer mere platforms for drafting designs but have evolved into intelligent systems capable of anticipating and adapting to the multifarious challenges of multi-material 3D printing. The journey thus far has been marked by significant milestones: the development of specialized simulation modules that integrate AI and machine learning, the rollout of automation tools and custom plug-ins that streamline complex workflows, and the transformation of user interfaces into comprehensible, data-rich environments. Each of these advancements plays a critical role in boosting production quality and shortening development cycles. By leveraging these state-of-the-art solutions, industries are now better equipped to explore the full potential of multi-material applications, driving innovation and efficiency in ways that were unimaginable a decade ago.

Embracing Future Possibilities

Looking ahead, the future of design software in multi-material printing appears exceptionally promising. With relentless optimization in simulation accuracy and adaptive process controls, future software releases are expected to provide even more streamlined and efficient production workflows. Key areas for future development include:

- Further integration of real-time sensor data into dynamic simulation models.

- Development of universal data standards that ensure seamless interoperability between diverse software platforms.

- Enhanced predictive analytics for preemptive error correction and quality assurance.

- Expansion of AI-driven customization features that tailor user experiences based on specific industry needs.

Summarizing the Path Ahead

In conclusion, we stand on the cusp of a transformative era in additive manufacturing where design software plays an instrumental role. The concerted efforts to overcome simulation inaccuracies, integration challenges, and real-time optimization hurdles have driven the development of powerful, intelligent tools that translate creative ideas into high-quality tangible products. With continuous improvements in algorithmic precision and multi-faceted user interfaces, the future of multi-material 3D printing promises to deliver enhanced design freedom, reduced production costs, and increased operational efficiency. As these trends solidify, the evolution of design software will not only support but also drive sustainable, efficient manufacturing practices—paving the way for a future where digital and physical realms coalesce seamlessly to produce revolutionary products.

Also in Design News

Mastering CAD with the 3Dconnexion Spacemouse: Five Compelling Benefits for Enhanced Design Workflow

August 26, 2025 6 min read

Read More

Cinema 4D Tip: Optimizing Transparent Backgrounds and Alpha Channels in Cinema 4D

August 26, 2025 3 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …