Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

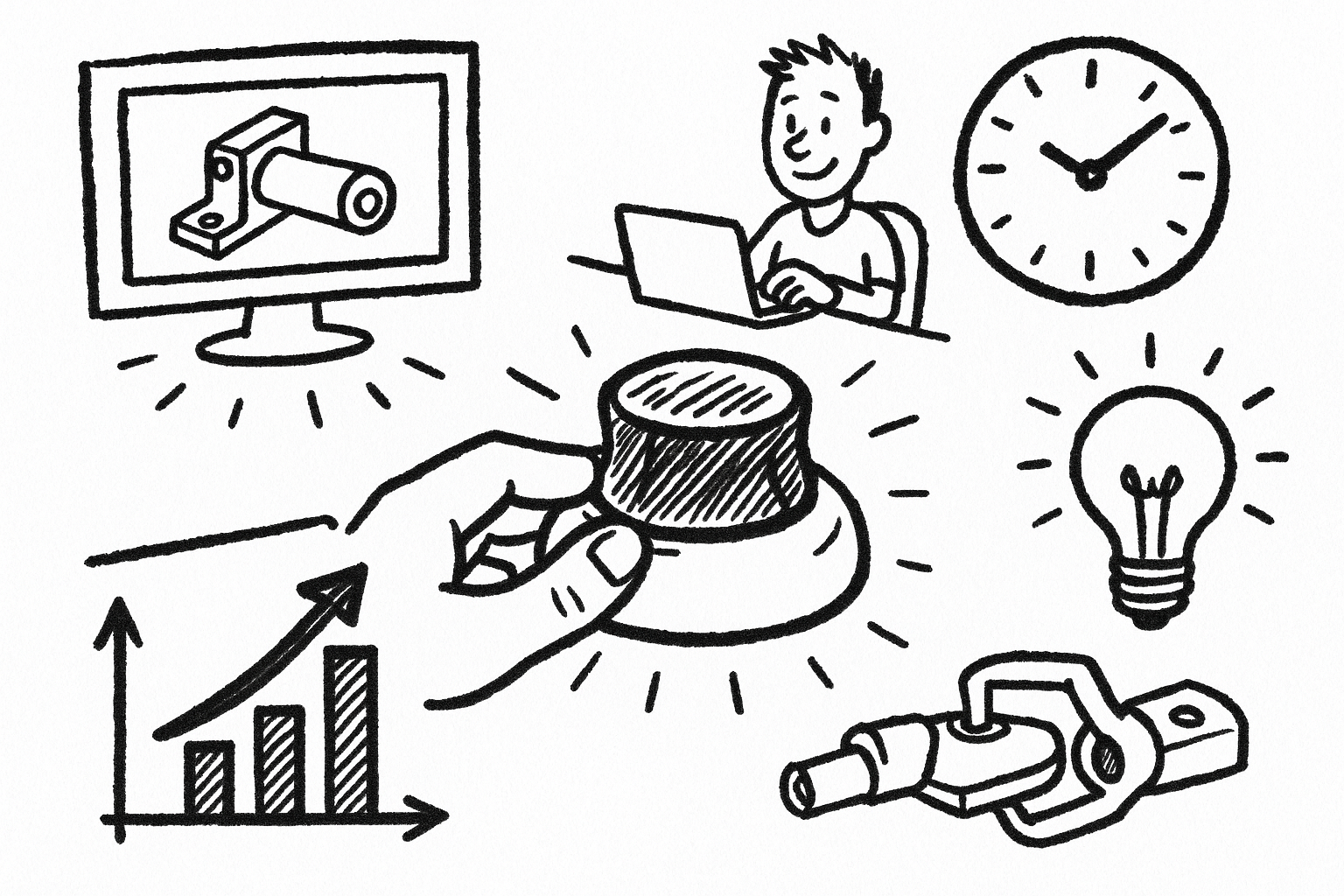

Mastering CAD with the 3Dconnexion Spacemouse: Five Compelling Benefits for Enhanced Design Workflow

August 26, 2025 6 min read

Introduction

Computer-aided design has evolved from wire-frame drafting to immersive digital prototyping, yet the input hardware on most desks remains a single scroll-wheel mouse identical to the one used for email or spreadsheets. As feature counts soar and schedules tighten, many professionals now reach for devices that eliminate interface friction and keep cognition focused on geometry rather than on keyboard gymnastics. The 3Dconnexion Spacemouse answers that demand, serving as a precision navigator purpose-built for complex models. What follows explores the five most compelling advantages this device contributes to a modern CAD workflow.

Immersive 3D Navigation Enhances Spatial Understanding

The heart of the Spacemouse is a six-degrees-of-freedom sensor that captures minute displacements along X, Y, Z and the three rotational axes. By resting a thumb and forefinger on the controller cap, a designer can pan, zoom, and rotate simultaneously with sub-millimeter fidelity. Unlike conventional orbit commands that lock movement into discrete steps, the motion here is analog and continuous, mirroring the way a physical prototype might be turned in one’s hands.

Consider a densely populated assembly—say an industrial robot with nested gearboxes. Navigating into a cavity normally requires a succession of view-cube clicks, scroll-wheel zooms, and right-drag orbits, each interaction interrupting mental focus. With the Spacemouse, a gentle push dives straight through the guarding, a twist rolls the viewpoint to align with the gearbox axis, and a slight tilt levels the horizon. The mind remains engaged with part relationships, not UI mechanics. The result is a measurable drop in visualization errors: interference checks expose clashes earlier, while design reviews proceed faster because stakeholders instantly grasp spatial intent from fluid demonstrations.

Benefits crystallize when switching between scales. Zooming from shop-floor overview to a single fillet is a single continuous gesture, so design intent at macroscale and microscale is validated in one mental sweep. By eliminating the cognitive “gearshift” imposed by view commands, the Spacemouse keeps designers mentally inside the model, a state that accelerates concept iteration and strengthens communication with collaborators.

Increased Productivity Through Two-Handed Workflow

Traditional CAD interaction is inherently sequential: move the cursor, click a command, adjust the view, repeat. Introducing a dedicated navigation controller transforms this linear dance into true parallel tasking. The dominant hand continues to drive the standard mouse—selecting edges, setting constraints, sketching profiles—while the non-dominant hand steers the Spacemouse cap.

- Sketch editing becomes smoother because orientation adjustments no longer interrupt line placement; the plane stays optimally oriented under the mouse cursor.

- Feature creation speeds up as the model can be spun or zoomed mid-dialog without dismissing the command.

- Annotation workflows accelerate when the view is aligned to each target surface in a single flowing gesture, then dimensions are placed immediately.

Empirical measurements inside tool vendors’ usability labs show task-time reductions approaching 28% for operations such as fillet application, part insertion, and exploded-view creation. Beyond raw speed, designers report entering a flow state, akin to playing a musical instrument: both hands coordinate subconsciously, minimizing mouse travel across command ribbons and eradicating the stop-start cadence caused by view resets.

That flow manifests strongly during conceptual phases. Imagine sculpting a consumer electronics housing inside subdivision modeling. The left hand rolls the model to reveal curvature transitions while the right hand pushes and pulls vertices. Surface continuity can be assessed and refined without ever leaving the modification tool. Ultimately, dual-handed input closes the gap between thought and execution, enabling rapid exploration that would otherwise require interruptive keystrokes.

Ergonomic Advantages Reduce Fatigue and Injury Risk

Repetitive stress remains an invisible cost in engineering departments, often surfacing after years of intense CAD usage. A traditional mouse, responsible for both navigation and command execution, forces elevated shoulder positions and frequent scroll-wheel flicks. The Spacemouse counters these issues through a design that emphasizes minimal force and balanced posture.

The controller cap responds to just a few grams of pressure, so wrists stay neutral and ulnar deviation is avoided. Because navigation tasks migrate to the non-dominant hand, the dominant side experiences fewer drag motions and scroll bursts, lowering the cumulative strain on extensor tendons. A weighted base anchors the device close to the keyboard, letting elbows hover comfortably at torso width instead of stretching outward across the desk. Over multi-hour sessions, users report noticeably lower trapezius and forearm fatigue.

Beyond immediate comfort, this redistribution of workload has long-term implications. Consistent exposure to intense mouse movements correlates with carpal tunnel and tendinitis. Shifting half of that interaction to low-force six-axis gestures dramatically cuts repetition counts. The device thereby aligns with occupational-health recommendations that encourage bilateral input and micro-movement variety. Organizations investing in Spacemice have seen reduced sick days linked to musculoskeletal complaints and lower turnover among senior designers who can maintain precision without physical pain.

Ergonomics also influence accuracy: a relaxed limb delivers steadier micro-movements, improving constraint placement and reducing inadvertent clicks. In other words, comfort directly feeds quality, reinforcing the argument that the Spacemouse is not merely a luxury peripheral but a safeguard for both human and project wellbeing.

Customizable Commands and Context-Sensitive Shortcuts

The Spacemouse line features programmable keys and on-screen radial menus that can host everything from simple keystrokes to complex macros. When the driver detects a running application, it loads the matching profile automatically, so the same button might initiate “Extrude” in SOLIDWORKS, “Push/Pull” in SketchUp, or “Set Keyframe” in Maya—without user intervention.

Power users exploit this capability to condense multi-step procedures into single actions. For instance, isolating a component, switching to section view, and fitting to window normally entails three toolbar clicks and a shortcut. By binding a macro to a thumb button, the sequence becomes instantaneous, shaving seconds off each inspection cycle. Across a product lifecycle comprising thousands of such cycles, the time dividend is substantial.

Radial menus add another layer of efficiency. A four-way or eight-way wheel appears under the cursor, letting the cap flick select commands in a fraction of a second. Because each menu is context-sensitive—one set for sketch mode, another for assembly—the UI surface stays uncluttered yet deeply powerful. A designer can keep one hand on the Spacemouse, eyes on the model, and still access dozens of commands.

- Custom profiles travel with user logins, so preferences follow engineers from laptop to workstation.

- Shared XML profiles enable team-wide standardization, supporting consistent workflows across departments.

This programmability does more than remove clicks; it codifies best practices into hardware, turning habitual sequences into muscle memory and reducing variability between team members. The cumulative effect is a studio that functions like a well-tuned machine, delivering predictable throughput and cleaner data sets.

Cross-Platform Consistency and Robust Software Integration

Engineering departments rarely operate inside a single operating system or application. A mechanical engineer may sketch in SOLIDWORKS on Windows, a visualization artist may polish renders in Blender on Linux, and an architect might iterate in Revit on macOS. The Spacemouse offers a rare constant among these shifting landscapes, with native drivers ensuring identical tactile behavior across all major OS environments.

This uniformity matters because muscle memory is sensitive. If the same slight clockwise twist zooms in on one machine but scrolls laterally on another, efficiency plummets. By standardizing input, the Spacemouse turns cross-platform work into a frictionless exercise. Certified plugins exist for over 300 programs, including niche FEA solvers and point-cloud viewers, so specialists can maintain the same navigation muscle memory whether they are meshing a turbine blade or staging a photorealistic animation.

The driver architecture also supports simultaneous updates. When 3Dconnexion releases a firmware enhancement—say, adaptive speed curves for ultra-large assemblies—the improvement rolls out to all connected applications at once. There is no waiting for individual software vendors to expose new APIs. This future-proofing protects the hardware investment: a device purchased today is likely to integrate smoothly with tomorrow’s toolchain, reducing procurement cycles and training overhead.

Finally, the Spacemouse doubles as a unifying training platform. New hires can learn a single interaction paradigm that scales from conceptual industrial design to BIM coordination. This shared baseline creates mentoring efficiencies, as senior staff need teach only design intent, not navigation workarounds. The broader implication is cultural: when every team member manipulates geometry with the same fluency, collaboration accelerates, and peer-reviews focus on creativity rather than on “how did you get that view?” explanations.

Conclusion

Adopting the 3Dconnexion Spacemouse transforms computer-aided design from a sequence of clicks into an embodied, two-handed craft. **Immersive navigation** keeps designers visually and mentally embedded within complex assemblies. **Parallel workflow** elevates productivity, while thoughtful ergonomics protect long-term health. **Deep customization** turns repetitive procedures into effortless gestures, and **cross-platform reliability** ensures the device remains an ally as software ecosystems evolve. For organizations seeking to elevate their modeling pipeline into a highly efficient, human-centric environment, integrating a Spacemouse is less a peripheral upgrade and more an operational imperative.

Also in Design News

Cinema 4D Tip: Cinema 4D Billboarding: Quick Setup and Optimization

February 28, 2026 2 min read

Read More

V-Ray Tip: V-Ray Edge-Preserving (Bilateral) Denoising Workflow

February 28, 2026 2 min read

Read More

Revit Tip: Revit Print Setup Standards for Consistent PDF Exports

February 28, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …