Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

The Edge: Paul Martin, Director of Engineering at Zahner

August 26, 2014 8 min read

Novedge: Tell us a bit about who you are and what you do

Paul Martin: Within Zahner, I work up front with architects and designers to develop projects. Typically we are contacted early on, in the Schematic phase, where a design team likes the concept of using metal in a façade, but needs assistance in material selection, finishes, system design, and (always) budgets. Everything we do is custom, so there is always a degree of development early on.

Personally, I was not involved with architecture or sheet metal in any capacity prior to Zahner. I have a mechanical engineering degree and had been doing 3D design work in the semiconductor industry in silicon valley. After relocating to Kansas City, I found Zahner on a whim. They were in the early stages of the Experience Music Project which can only be comprehended is 3D. That was also the development of the first generation of the ZEPPS technology.

Novedge: What is or has been the biggest influence on your work?

Paul Martin: We are in the position of not imposing a style or aesthetic on a design, but rather we facilitate other people's designs. We have developed systems and technologies to allow us to realize very complex geometries and intensive numerical challenges. I would say that the person with the biggest influence on my work (and the work that the company does) is Bill Zahner, CEO and President. Zahner is a 4th generation company, but Bill got us steered in the direction of high end custom architectural work. His passion and drive is amazing and infectious. We seek out the most complex work and never do the same thing twice. His capacity for risk enables us to take on the hardest work. Where most contractors have relationships with General Contractors in order to secure work, we align ourselves with the design community.

Novedge: What is your approach to collaboration and team work?

Paul Martin: Our work tends to be very relationship based with a design team. It’s vital that we understand design intent when working so early in the process. Inevitably there will be changes to scope and design, so it’s important to know the underlying intent. We often work in a design assist capacity during pre-construction. This allows us to work directly with the design team in order to develop system details, consider material and finish options, create 3D models, construct full scale mockups, etc. to develop the design to a stage where it is fully understood and specified. We bring the experience and know how to inform the design and optimize for fabrication and installation. It often helps the process to impose constraints on the design to further the process. Budget is always a constraint, we want to know up front what the budget is so we can design to it. Unlike consulting firms, our business model is based on making things. The design process is a means to the end, but where we can have very significant contributions.

Novedge: When working with large teams, how do you handle coordinating and supervising everybody's work?

Paul Martin:This happens in a couple of different respects. During preconstruction we typically work with a design team, general contractor, owners representative, consultant, maybe a few others. Once we are under contract and in production, we have a large internal operations group that needs to have an understanding of the project deliverables. We don’t operate under a plans and specs model, there is usually some nuance to the design that isn’t necessarily captured in documents. I’m on a roll to make sure that there is continuity from the start of the design process to the end of construction. As always, communication is the key, making sure that there is a common understanding of the end goal.

Novedge: What is a recent project that you worked on?

Paul Martin: We’ve got a nice little portfolio of work in San Francisco.

In addition to the de Young, there is the Contemporary Jewish Museum, which tends to fly under the radar, even in the City. It’s one of my favorite Libeskind projects. We had been involved with the project since the late 90’s when Libeskind made his original designs. There was a lot of turmoil with the organization (not to mention the economy) which resulted in it being on hold for many years.

The building was scaled down dramatically when it was redesigned, and I think it’s much better for it. Colored stainless steel was an integral part of the design. We worked with our vendor in the UK to come up with a custom finished material, it’s the only time it’s been used. It’s a blue interference color on stainless steel with a brushed finish in two directions. What is great about it is the way it gives the building life and vitality, which is a central theme in Libeskind’s design. The surface is always changing in different light. It was also a technically challenging project because of the exacting nature of the design. The panel pattern wraps over the edges and there are concealed gutters at the perimeter. The panels have no reveal or gaps, no tolerance at all. It’s a deceptively simple looking building. There is a complex system of extrusions, insulation and waterproofing underneath the metal skin which provide for tolerance and movement, all of which had to be precisely laid out and installed. We were challenged by the architects to provide perfectly flush skylights, something that could not be obtained by a skylight manufacture. We came up with a system that integrated the skylights into the design of the panel system. It all came together in a nice, tight package that still looks new today.

It’s not the highest profile, but we recently completed a parking garage for UCSF in Mission Bay that I’m very proud of. It’s designed by the excellent local SF firm WRNS, whom we have worked with on several projects, and is a great example of collaboration. They called when they were at the competition stage with a very strong concept of what the façade should be, which really is what differentiates a parking garage. We committed to an extremely aggressive budget number at the competition stage based on our experience of working with them on collaborative design. We worked with them to optimize the design for best material usage, and efficient fabrication and installation. I think that the end result is a perfect testament to really smart design. We used a custom shaped extrusion for the fin system, but they were all the same part (4400 total). By changing the angle of the extrusion the designer generate a dynamic surface. If you are on Caltrain, or the highway, or even just walking around it, the surface changes with your viewpoint.

Novedge: What software do you use?

Paul Martin: It might be easier to list the programs we do not use. We are in the position of having to work with everyone else’s models, so we see a lot of Revit, Rhino and Sketchup. Architects all have different ways and degrees to which they create and maintain a model, so we have to have capabilities to work within their process and take what they have and make it work for our own fabrication process. We have even scanned physical models to create surfaces and we work with some of the most advanced architects (Morphosis is a great example, we developed much of Emerson College with them to optimize material usage and patterning/geometries. The project was under great budget constraint, but rather than abandoning it, we worked jointly to make it the extraordinary project it became).

That said, internally we have standardized on Digital Project from Gehry Technologies. We are a very niche company, no one makes an optimized software package for fabricators working on a custom architectural scale as we do. At the end of the day, we are fabricating material, so we do a lot of scripting and programing within DP to automate processes. Before that we relied extensively on ProEngineer, a package that is not used in the architecture realm at all.

Our work is custom, any given assembly we create may have dozens of all unique parts, and the may be hundreds of assemblies on a project (a large ZEPPS project like NASCAR or Miami Intermodal) so a lot of what we do with the software is logistics related; being able to generate massive amounts of data (individual part files for fabrication) efficiently. This also bleeds over into shipping and part tracking. We have optimized systems to help with our field crews that install the parts, including 3D viewers as many of the project we work on can’t really be understood with traditional 2D drawings.

Novedge: What has been the biggest challenge in your career and what have you learned from it?

Paul Martin: On a project basis, the de Young Museum was one of the most challenging. It was a bit unique in that we owned the entire exterior envelope, so we had 10 or 12 subcontractors under us during construction.

The design itself was immensely challenging. Early on we had worked with Herzog and de Meuron on the concept of taking data from a digital image and making a direct translation onto the façade. We had a dedicated computer programmer working for 18 months to come up with a system that eventually led to the ZIRA technology for image translation. By the end of the process we had a fully automated system that the designers in Basel could upload images to, and it would automatically generate translated cad files. It became a design tool that the architect could independently develop with, and it also fully integrated into our production system. The program interpolated the image on a pixel by pixel basis and translated it into features (holes and/or bumps) on the skin surface. We worked with the design team on all aspects of the façade. They had a clear vision on the glazing system and how it integrated with the skin. We had to coordinate with all of the separate components (copper skin, waterproofing, roof, TPO roof under copper, doors, glass, glazing frames, etc.) to produce a unified building. The lesson was one of rigor and perseverance. The construction itself lasted two years, with daily issues that needed resolution. I moved to San Francisco to support the project, so it was a very trying but ultimately rewarding experience.

Novedge: What innovations do you find most exciting in your field?

Paul Martin: It’s been fascinating to have a front seat view of the integration of 3D modeling within the architectural industry. I started with the company in 1998, working on Gehry’s EMP. Gehry’s team was very advanced in their modeling. I always appreciated that they didn’t use a model for rendering, it was used for building. They modeled the steel back when steel companies themselves were not doing it. They were on the forefront of BIM. In the years since, we’ve seen a total proliferation of the tools, but a wildly varying degree to which they are fully implemented. Architects, contractors and owners are now seeing the benefits of a fully integrated model, but it’s common to see a “BIM” approach not follow through on its potential. Liability seems to be an issue, many designers won’t or can’t have a 3D model as a contract document.

The tools are also allowing for an unprecedented amount of experimentation in surface geometries and complexity. Young architects especially are completely fluent in digital design. We’ve been able to play a role in taking these ambitious designs and working through manufacturing challenges.

Zahner has an environment of constant innovation. One example that we are very excited about is our recent (and ongoing) development of a suite of tools under what we are calling “ShopFloor”. The concept is to give designers web based tools so they can generate their own designs. We hope to empower the design community, you can get price quote for your unique design right off of the tool. It’s a disruptive idea within the industry. The tools will feed files directly to our CNC equipment to make the most efficient fabrication possible.

See more of Paul's work and lean about Zahner's approach to working with the architectural community here. For the latest news from Zahner, follow them on Twitter, Facebook or LinkedIn.

And don't forget to subscribe to the Novedge Blog for new interviews and original posts every week!

Related articles

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

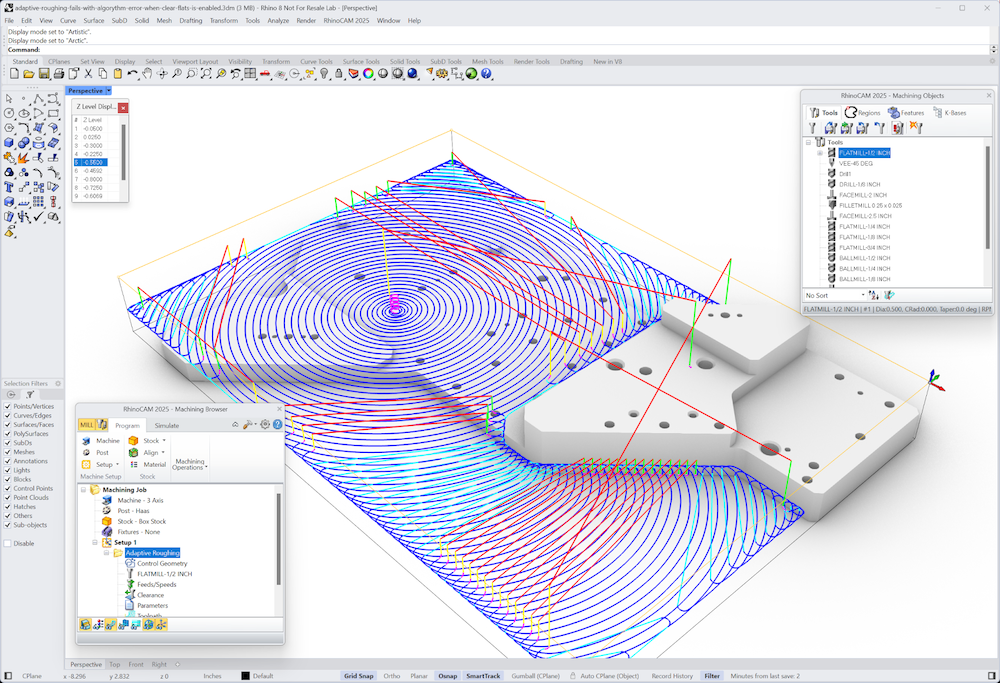

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …