Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

An Interview with Roberto Ciarloni, think3 CTO

July 29, 2008 7 min read

Current CAD systems are all based on only a few core geometric engines. Among those software engines, the ones that integrate solid modeling with free-form surfaces can be counted on one hand. One of those few engines is made by Think3, an Italian company that has been trying for several years to enter the US market with an interesting and powerful CAD solution. The key person behind think3 software is Roberto Ciarloni, Chief Technology Officer. I’ve known Roberto for a long time and I’m glad to have the opportunity to interview him for the Novedge blog. Here are my questions and Roberto’s insightful responses.

Roberto, can you tell us a bit about yourself and your company?

In my 24 year career I have participated to the birth and evolution of three-dimensional CAD systems. I have contributed to the architecture and development of several CAD products in a very demanding market. Some of these products are still used by thousands of companies around the world. I have started with B-Spline surfaces, migrated to NURBS, and then to Boundary-Representation solid modeling. I have led teams of developers in locations around the world, innovating the software development process. I have been professor of computer graphics at the University of Milan where I have tried to systemize the interdisciplinary subjects of CAD and 3D modeling.

some of these products [I developed] are still used by thousands of companies around the world

Currently I hold the position of Chief Technology Officer in think3 and my job is to explore new directions and new technologies in the 3D CAD world. Think3 is a privately held company that operates in the CAD and PLM business. Think3 provides CAD products (ThinkDesign) in the areas of mechanical and industrial design. It also provides PLM products (ThinkPLM) to help engineering departments in managing their data and their activities. Together with off-the-shelf products think3 offers consultancy in the CAD/PLM domain and helps companies who want to move some design activities off-shore.

Direct Modeling seems to be the new trend in CAD. What is think3’s approach to this technology and your long term goals?

Indeed direct modeling is gaining a lot of attention at this time. As you know this approach is as old as the “standard” history-based approach but in the past it has never been able to be competitive. Now times have matured mainly because the traditional Pro/E-like products have become more and more complex to use. The potential of direct editing is great because it allows a much more natural interaction with the model and does not require extensive training to be used.

the potential of direct editing is great because it allows a much more natural interaction with the [3D] model

I have been fond of it for a long time and my team delivered it in ThinkDesign in 2006 under the name ISM (Interactive Solid Modeling). The reaction of our customers has been enthusiastic and we have gotten a lot of pressure to extend and improve it. However I believe that this approach will never replace the history-based approach but rather will complement it. The history graph of a parametric model contains a huge amount of information and design intent and it will never be possible to replace it using things like feature recognition to feed the direct editing approach. In some sense a parametric model is a program to build a family of models and we know that in principle it is impossible to reconstruct a program just by sampling its behavior.

In Think3 we believe that a modern CAD system must allow several modeling strategies. I’ll talk more about that later in the interview.

Our plan on Direct Editing/ISM is to extend its application outside the traditional part modeling where it was born. We are now applying it to design problems in tooling and we are studying its application in assembly design. At the same time we are working hard on the base geometric algorithms to improve its reliability and applicability in complex situations.

Many companies are outsourcing big chunks of their design activities to India and China. What is the impact of these changes on the way CAD systems are used ? How is this kind of outsourcing influencing the evolution of think3 CAD system?

Think3 indeed has a branch of its business dedicated to help companies to outsource design activities to India, where think3 has set up several design centers working on a project basis for European companies.

think3 has set up several design centers working on a project basis for European companies

We feel that this trend is strong and we want to exploit our competence in design services and in outsourcing.

This trend is influencing CAD products (including ours) in two ways: we need systems that are easier to use and more standardized, so that the average engineer will take less time to exploit them, and we need a software that is able to digest low-quality data without a glitch. This sometimes means healing the model but also it means much more powerful and intelligent algorithms. I think that this is definitely one of the challenges for the years to come.

How far can the integration of the two technologies of direct-modeling and parametric-modeling be pushed without turning the CAD system into some sort of Frankenstein?

I have read about this objection and frankly I don’t see it as a big problem. In thinkdesign the ISM functionality can be inserted in the history graph like the other features or it can be used without history. I think that the objection relies on the case of a traditional feature (e.g. a hole) with some relations and parameters that can be “tweaked” by a later ISM modification so losing its semantic. But the same tweak can happen also with traditional features like face draft so where is the difference?

think3 is providing also a third modeling approach that is Global Shape Modeling (GSM)

It must be pointed out that think3 is providing also a third modeling approach that is Global Shape Modeling (GSM). In this powerful approach the user can make editing using shape semantics like bend, twist, or even change from one section to another. This approach is much better suited for complex shapes where the face-dragging metaphor of direct editing is less appropriate. So in think3 we provide the user all the freedom and the potentiality to obtain the shape he/she has in mind.

Looking at the parametric-modeling and direct-modeling technologies, is it possible to identify categories of users or types of organizations that are more likely to benefit from one specific approach rather than from the other?

SpaceClaim has recently tried to divide the field: parametric history-based for designers and direct editing for all the others (e.g. persons in manufacturing or marketing departments). It sounds reasonable but I feel it’s a bit too shallow: how to coordinate the changes? (Especially if the departments use different CAD programs as SpaceClaim is pushing). However having systems like ThinkDesign or others able to provide all approaches will tell us how the companies’ organizations will exploit them and so maybe the SpaceClaim classification will prove to be roughly correct.

direct editing seems better in the conceptual stage of design

A classification that comes to my mind is that direct editing seems better in the conceptual stage of design where it can be too hard to build all the parametric relationships and rigidity to discover that the design needs a radical change.

What’s your approach in utilizing user’s feedback into the development process?

The users’ feedback and requests are inserted in our process in many ways. Marketing, Sales, and Customer Care daily filter all the customer base input and update our databases of bugs, requests, and use cases. These data is then processed regularly to influence releases’ content.

we encourage in several ways the contact between developers and customers

However we don’t believe in the approach where developers are just executors of someone else’s plan and so we encourage in several ways the contact between developers and customers to increase the developer’s sensitivity in real customer problems and attitude.

Obviously no meaningful product can be done just by collecting customer requests and so we try hard to insert a precise vision and mission in our products. For example one of our visions is to achieve both high-quality modeling precision and ease-of-use, two concepts often in contradiction with each other.

What are the challenges in 3D CAD that you see for the near and medium term?

There are dozens of challenges that are still to be solved in 3D CAD. Among them I will quote reliability, interoperability, collaboration, knowledge capture, and bad data management. However there is still a more basic challenge that awaits a better solution: 3D is still difficult.

there is still a more basic challenge that awaits a better solution: 3D is still difficult

I will describe this problem in a simple way: given a complex 3D object and given a modern 3D CAD system (e.g. Solidworks, ThinkDesign, etc.) what are the commands to use to model it? Consider the same situation with a 2D object and with AutoCAD: even a very poorly trained person will achieve the goal quickly using lines, arcs, trim, extend, etc. I think that this difficulty will never vanish completely due to some intrinsic mismatch between the 3D space and our perception system but we have still a long way to go to improve the situation. As stated above one of the keys of the success of direct editing has been exactly that is going in the right direction. For me the most misleading statement that is often mentioned in relation to this is “we must build a system as easy as clay modeling”. But achieving a definite and precise shape with clay is unbelievably difficult! Ask the modelers who build automotive mockups. So we are back to the challenge to imagine and envision new ways to define 3D objects.

I would like to thank Roberto Ciarloni for taking the time to answer all my questions. If you have any questions for Roberto or for Novedge, please leave a comment below and we will be glad to answer. All think3 products are available in the US through the Novedge website.

Franco Folini

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

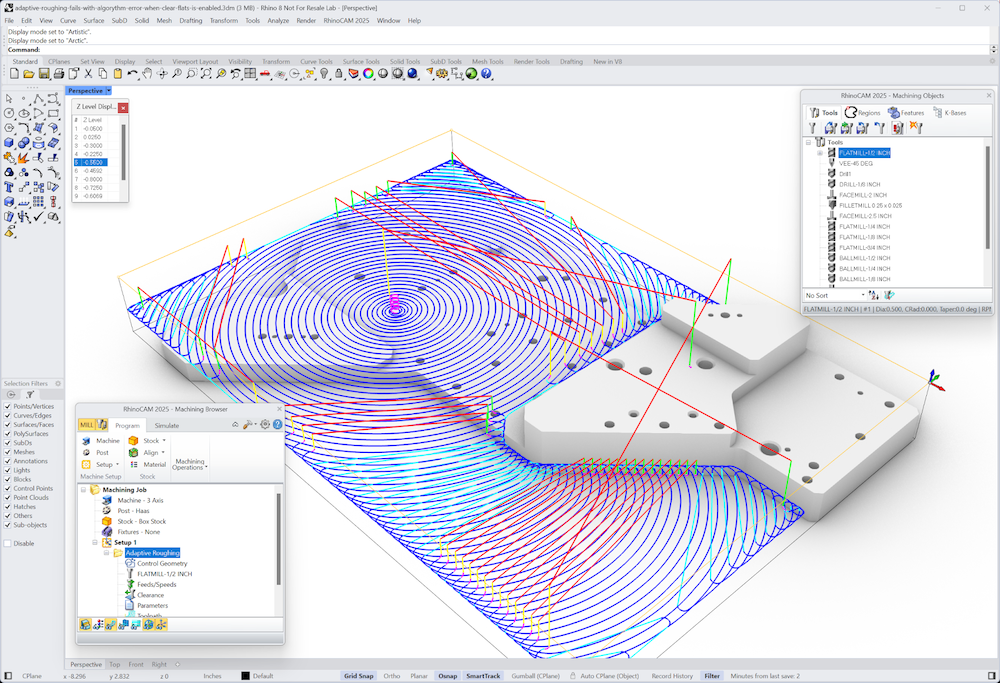

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …