Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

An Interview with Robert Green, author of “Expert CAD Management”

July 23, 2007 6 min read

Robert Green is the author of the new book Expert CAD Management: The Complete Guide (288 pages, published by Sybex) and the head of the Robert Green Consulting Group. Robert is well known for his insightful articles published by the popular Cadalyst magazine. Having spent a few years myself as a consultant to support CAD users in SMEs (Small and Medium Enterprises), I learned how important and at times difficult this job can be. Therefore I sincerely welcome Robert Green's book as I'm sure it could help all CAD managers to fully understand the extent and limitations of their responsibilities, thus providing a better service to their companies and CAD users. I invited Robert for an interview in order to share some of his highlights from the book. Here are my questions and his answers. Please note that if you order Robert's book from his website you will receive a signed copy.

Robert, can you tell us a bit about yourself and your professional activities?

I’m a mechanical engineer who got bitten by the CAD bug way back in 1985. I had the opportunity to learn AutoCAD at version 2.0 while also using SDRC’s I-DEAS program to model and analyze large mechanical assemblies for semiconductor machinery. Somewhere along the way I became “the go to guy” for CAD applications and got the reputation of being the CAD manager. I never really sought out the title, it just sort of happened.

Through the unfortunate event of a bankruptcy at the company I worked for I found myself without a job in 1991 and decided to start my own company providing CAD consulting services and I’ve been at ever since. I started writing professionally in 1996 for CADENCE Magazine which lead to my current involvement with Cadalyst Magazine and ultimately my new book. I also do a lot of teaching and public speaking on CAD management topics.

How does your book make a difference in the everyday work of a CAD manager?

CAD managers can use the book to expand their awareness and widen their skill

I’ve tried to make the book a complete guide (thus the title) on a broad variety of subjects from technology to personnel management to return on investment and budgeting. I think the breadth of topics in the book is a metaphor for how varied the CAD manager’s job really is. The best thing I can do for CAD managers is make them realize that their focus needs to be on a lot of items that aren’t necessarily CAD. After all, the word MANAGER is a lot bigger than CAD right?

I structured the book to have a unifying beginning section that every CAD manager should read then they can branch out into the other chapters depending on what’s applicable to them and what they feel are their weaknesses. My hope is CAD managers can use the book to expand their awareness and widen their skill set at their own pace.

What would be the background and personal features of a great CAD manager?

there’s no substitute for understanding the industry you work in via real experience

Background wise there’s no substitute for understanding the industry you work in via real experience. As an example, a mechanical engineer will be a better CAD manager in a manufacturing plant than an architect would be due to contextual experience. When you understand your user’s needs and how the company operates you’ll be a better CAD manager but you can only gain that perspective via experience. Exposure to some financial concepts like budgeting or engineering economics are great skills to have coming into a CAD management position, though you can learn those skills as you go.

Finally, I think the most important personal attributes of a CAD manager are the ability to learn on their own, a desire to solve complex technical problems and the willingness to take responsibility for a wide variety of tasks.

In your professional activities, do you spend more time sensibilizing people about CAD management or providing practical solutions and tips?

understanding why a problem exists will allow to remove the root cause of the problem

Actually it all seems to happen concurrently. I try to present things in the sequence of “what is the problem” then “why are you having the problem” then “what might you do to solve the problem” as the last piece of the puzzle. Typically it is during the “why are you having the problem” phase where the light bulb goes on for most CAD managers. That’s usually where they start to see their job as being more user based, more educational, more managerial and somewhat less technical than they might have thought.

When I give lectures to CAD manager groups I strive to demonstrate that understanding why a problem exists will allow them to remove the root cause of the problem. Then solutions can flow quickly once the root cause is eliminated. I do like to challenge CAD managers to think about the strategy of what they’re doing so they’ll take fresh new approaches to old problems. My goal is to have them walk out of a class emboldened to take charge and make things better.

What are the most common mistakes in CAD management in SMEs (Small and Medium Enterprise)?

(the main mistake) CAD managers aren’t talking to senior management in senior management’s native language

The most common mistake I see is the CAD manager not being involved enough in planning for future technology like hardware, networking and the new generation of design tools we see being adopted. When I hear a CAD manager complain about not having the right hardware, software or adequate budgets my first question is always, “What did you tell your management you needed?” After all, most senior management staffs know less about CAD than the CAD manager does so it behooves us to get involved in the planning early on.

The other main mistake I see made is that CAD managers aren’t talking to senior management in senior management’s native language which is all about business and money. If you approach senior management with a solid business plan and show why that plan will generate profits for the company you’ll do a lot better than talking bits, bytes and bandwidth.

The transition from 2D to 3D can have huge implications for a CAD manager. What issues come up the most?

changing user’s software tools (from 2D to 3D) can be traumatic

The biggest issues I see are the human factors of the transition like training and desire to change. Changing user’s software tools can be traumatic and can lead to a divided user community: Some wanting to learn, some in the middle and some who simply loath change. But no matter what users think, the company simply wants their new software investment to pay off and is impatient to see the results. The CAD manager is now stuck between users who are stressed out by change and a senior management staff that wants things done immediately. Not an easy place to be!

Of course there are still the issues of upgrading hardware and software tools and fighting the budget battles that inevitably come up but in my opinion those things are easy compared to the staffing/training issues.

How does CAD management differ in a pure 2D environment from a 3D environment? What are the specific problems in the 3D environment?

3D tools require a lot more thought about data management, versioning and workgroup security

It differs in the amount of information that needs to be managed and carries a bigger emphasis on complex file to file relationships. Managing static 2D AutoCAD files is very different from managing a dynamically changing mechanical assembly with a collaborative design team, as an example. 3D tools require a lot more thought about data management, versioning and workgroup security.

There’s also the fact that 3D tools are developing/changing a lot more than the now familiar 2D systems so there’s more change to stay ahead of and bigger learning curves for the CAD manager as a result.

Finally, the interaction between 2D and 3D systems to facilitate communication with customers and vendors who use different systems is a big problem. I call this mixture of 2D/3D the hybrid CAD office and have observed the phenomenon in all manner of private and government environments. The translation headaches that result from the hybrid environment really keep the CAD manager hopping.

I would like to thank Robert Green for his taking the time for this interview. If you have any questions for Robert or for Novedge, please leave a comment below and we will be glad to answer. If you purchase Robert's book through his website the copy you receive will be autographed by the author.

Franco Folini

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

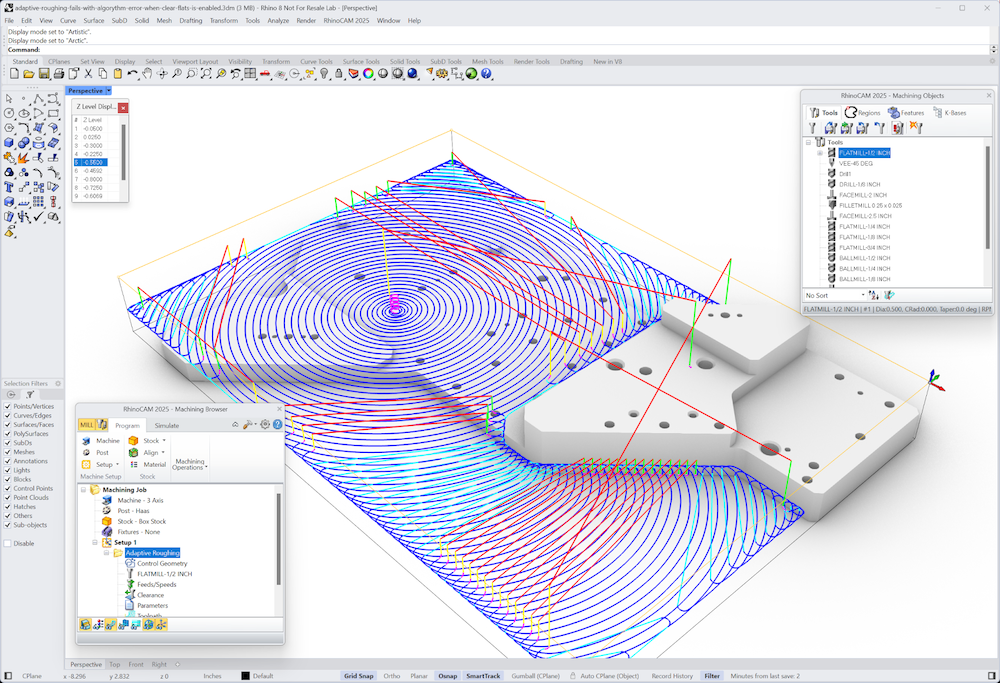

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …