Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

An Interview with Francis Cadin, CEO of Datakit

June 28, 2007 5 min read

Francis Cadin is the CEO and founder of Datakit, the French company specialized in CAD data translation. Datakit products come in two different flavors: some translators perform their sensitive tasks embedded under the hood of a software program while others come as plug-ins or standalone applications. For example, if you are opening a SolidWorks file with your Rhino 4.0, you may not know that all the data conversion between the two file formats is handled by a piece of software developed in Lyon, France by Datakit. Nowadays the CAD data translation seems to be less problematic than in the past. While the CAD market consolidation certainly made things easier, most of the credit goes to companies like Datakit and to people like Francis Cadin. I asked him to share his experience and opinions on this topic. Here is the interview.

Francis, can you tell us a bit about yourself and your company?

we have a staff of 25, twenty of whom work in R&D and technical support

Datakit is a privately-owned company that I founded in 1994 and that is specialized in CAD data exchange. I set up Datakit because I was convinced that the development of the use of CAx(CAD, CAM, CAE) solutions was going to generate a large volume of CAD data exchange. The company has grown. Now we have a staff of 25, twenty of whom work in R&D and technical support. In 2006, we launched Datakit, Inc. in California and we are currently looking at a project to open an office in China. Our products, plugs-ins, standalone applications, vendor-embedded components, and data correction solutions have been successfully adopted worldwide.

CAD Data translation is not a perfect science. During the process something always gets lost in translation. How do you usually explain this to your customers?

CAD Data translation is not a perfect science

No, CAD Data translation is not a perfect science but you have to acknowledge that most of the limitations are linked to weaknesses in standard formats like IGES and DXF. We based our technology on the modeling paradigms used in the original models and assemblies. Hence our strong attachment to native formats, which alone let users recover complete CAD data structures and maximize the number of entities exchanged. We can make a commitment to being able to read specific items of data. The rest is a question of resources! However, reading native formats is not always easy. Users are savvy to the fact that software architecture always has some surprises in store.

Data translation is quickly moving from being packaged as a standalone application to being embedded inside CAD systems. What are the challenges in making a software module compared to developing an independent application?

Datakit collaborates as an OEM with some fifty vendors

We are focusing on breaking down the entities into the finest grained detail possible and on building structures that enable data to be stored thoroughly and then used as needed by different applications. Data exchange impacts an increasing range of disciplines. This makes it natural and imperative to work with vendors to enable as many end-users as possible to exchange their CAD data. Datakit collaborates as an OEM with some fifty vendors. Supplying these software components accounts for 70% of our revenue. This upstream collaboration delivers benefits to end users in industry who can turn to local dealers in our network for support.

You recently moved with a part of your company from France to Santa Barbara, CA. How is your perception of the US market changing now that you’re looking at it from the “inside”?

It is true that the US market looks different from here. Flying over from Europe, even regularly, is no substitute for day-to-day contact! Seen from across the Atlantic, the potential of the US market is huge, with so many world-famous vendors here. Even more striking though is the dynamism of the market, its ability to keep on creating new products and the positive attitude in the business.

The consolidation of the CAD market has greatly reduced the number of CAD systems. Has this evolution also reduced the need for data translation? How have the end-users’ needs changed in the last few years?

the consolidation (of the CAD market) does not have an immediate effect on data exchange strategy

If you look at just the CAD market, the number of players has thinned a bit, though in my opinion, that doesn’t tell the whole story. Some companies have disappeared but others have emerged. Consolidation does not necessarily have an immediate effect on data exchange strategy. Compatibility issues have not moved on much. On the contrary interoperability issues have increased the need for data exchange and considerably exceeded the scope of CAD. CAD models provide a working basis for more and more disciplines. In technical terms, the substantial growth over the last few years is the switch from IGES surface data to STEP, which does a much better job of handling solids and assembly data.

Datakit “promiscuity” (your software is embedded in competing products from different manufacturers) places you in a privileged position to observe new trends. What is going to be the evolution of current CAD systems?

exchanging 3D models that have dimensioning and tolerancing data is essential

The current trend is of course all about managing FTA (Functional Tolerancing & Annotation) modules from CATIA V5, UG’s PMI(Product Manufacturing Information) and all the other data of this type. Companies must work from these modules to increase productivity. Exchanging 3D models that have dimensioning and tolerancing data (GD&T) is of course essential. Datakit has been proactive in this area for the last 4 years. We have been working with vendors of data inspection solutions for whom the ability to build this information into the 3D model is an additional guarantee of quality. Viewer developers who facilitate access to CAD data are also among our prime targets. Manufacturing departments are also interested and this could lead to 2D paper drawings disappearing completely from many workshops.

If you were a CAD manager and had to choose a file format for the long term archival of your company strategic data, which file format would you choose, and why?

we would recommend (long term archival) of 2D in DXF, then IGES (for 3D). However, given

the limits of IGES, we would also add STEP

Ideally, and on the strength of the data we have at the moment, we would recommend three methods. The first for 2D in DXF (V12 for example), then IGES for its robustness and availability across all software brands. However, given the limits of IGES, we would add STEP. It’s a neutral format, independent from hardware and CAD systems. It provides a comprehensive and unambiguous description for 3D models. It also supports association of Validation Properties, which makes it possible to check the validity of imported data (either as simplified volumes to view parts and assemblies, or clouds of points for detailed face representations). In fact we agree with the specialists of the LOTAR project who recommend the software and define how it should be used, arguing that it is the only way to process all the data in the CAD model, assemblies and their dimensioning and tolerancing information.

I would like to thank Francis Cadin for taking the time to answer my questions. If you have any questions for Francis or for Novedge, please leave a comment below and we will be glad to answer.

Franco Folini

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

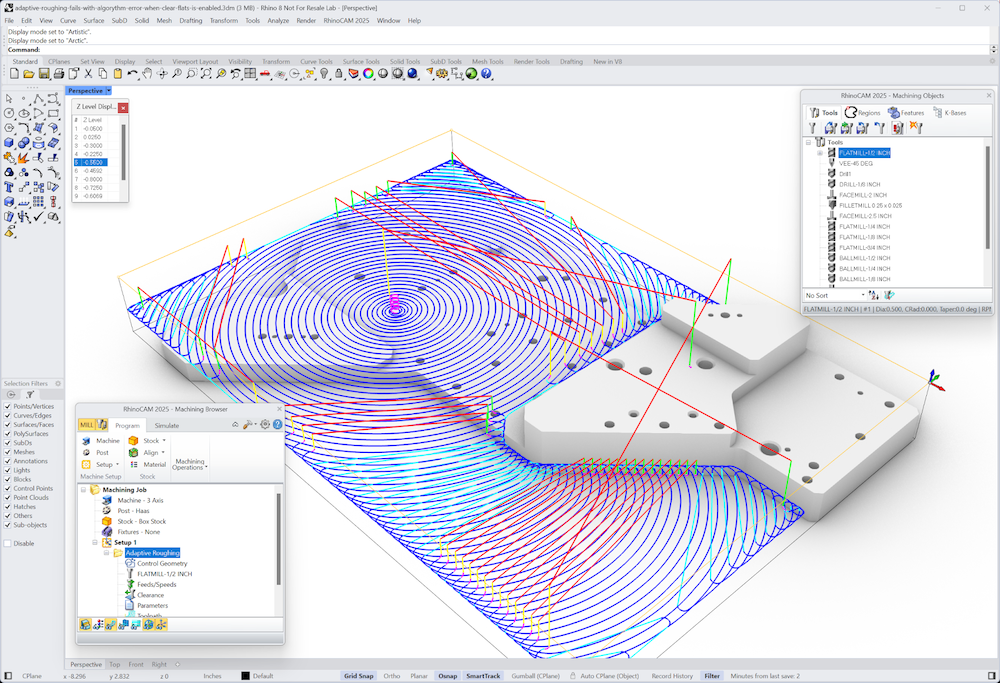

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …