Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Top 5 Strategies for Optimizing Large Assembly Management in PTC Creo

February 11, 2025 5 min read

Introduction

Overview of Challenges with Large Assemblies in PTC Creo

Working with large assemblies in PTC Creo can be a complex and resource-intensive task for engineers. As assemblies grow in size and complexity, they often lead to performance issues such as slow loading times, lag during navigation, and extended regeneration periods. These challenges not only hinder productivity but can also jeopardize project timelines if not managed effectively. The intricacies involved require strategic approaches to ensure that efficiency and accuracy are maintained throughout the design process.

Importance of Effective Assembly Management

Mastering effective assembly management is crucial for engineers to navigate the complexities of large models. By employing proper techniques, engineers can achieve smoother workflows, reduce system strain, and produce better design outcomes. Effective management enhances collaboration, minimizes errors, and ensures that projects stay on schedule, ultimately contributing to the overall success of engineering endeavors.

Introduction to the 5 Key Strategies

This article presents five essential strategies to optimize large assembly handling in PTC Creo. By integrating these techniques into your workflow, you can overcome common obstacles associated with large assemblies and enhance both performance and productivity.

Utilize Simplified Representations

Understanding Simplified Representations

Simplified representations in PTC Creo are alternate versions of models with reduced detail. They allow engineers to manage complex assemblies by excluding non-essential features, thereby reducing the graphical and computational load. By focusing on the critical aspects of a design, simplified representations help maintain efficiency without compromising the integrity of the model.

Creating Simplified Representations

Follow these steps to create a simplified representation:

- Open your assembly in PTC Creo.

- Navigate to the View tab and select Simplified Rep, then click on Create.

- Name your simplified representation appropriately.

- Select the components or features to exclude or simplify based on their relevance.

- Save the representation for future use.

When choosing the level of detail, consider:

- Retaining features critical to your current task.

- Removing small or internal features that do not impact the overall design.

Benefits of Using Simplified Representations

Simplified representations offer several advantages:

- Enhanced graphics performance due to reduced rendering requirements.

- Faster regeneration times when making changes to the model.

- Reduced memory usage leading to improved system stability.

- Improved loading times for large assemblies.

Best Practices

To maximize the effectiveness of simplified representations:

- Regularly update them as the design evolves to ensure accuracy.

- Utilize simplified reps for tasks like clash detection and assembly motion studies.

Implement Lightweight Components

What are Lightweight Components?

Lightweight components are simplified versions of parts or assemblies that contain essential geometric information without detailed features. They differ from full-detail models by using less memory and improving performance when handling large assemblies. Lightweight components allow engineers to work efficiently on complex projects without unnecessary system strain.

Loading Assemblies in Lightweight Mode

To load assemblies in lightweight mode:

- Go to File > Open and select your assembly.

- Click on File Open Options before opening the file.

- Under Representation, choose Automatic or select a specific lightweight representation.

- Open the assembly with these settings.

Adjust settings for automatic lightweight loading:

- Modify the

enable_assembly_lightweightoption in config.pro toyes. - This ensures components load in lightweight mode by default.

Advantages of Lightweight Components

Using lightweight components provides:

- Faster loading of large assemblies.

- Improved navigation with reduced lag during pan, zoom, and rotate operations.

- Efficient management of system resources, allowing focus on high-level design aspects.

Considerations

Keep in mind:

- Components can be refetched in full detail when detailed features are required.

- Some operations may be limited on lightweight components, necessitating a switch to full-detail models.

Optimize Display Settings and Graphics Performance

Adjusting Display Settings

Optimizing display settings can significantly improve performance:

- Reduce display accuracy by adjusting the tessellation settings to lower levels.

- Use the level of detail option to automatically simplify model display when zoomed out.

- Enable culling to hide components not currently visible in the workspace.

Enhancing Graphics Performance

Enhance graphics performance by:

- Updating graphics drivers to the latest versions for compatibility and efficiency.

- Enabling graphics acceleration features within PTC Creo, such as OpenGL support.

Managing Visibility of Components

Manage component visibility to reduce system load:

- Utilize layers to organize and control the display of parts.

- Create zones to isolate and work on specific sections of the assembly.

- Apply display states to switch between different visibility configurations quickly.

Impact on Workflow

Optimized display settings result in:

- Smoother workflow with reduced lag and improved responsiveness.

- Efficient modeling as focus can be directed to active design areas without unnecessary distractions.

Apply Top-Down Assembly Design Techniques

Understanding Top-Down Design

Top-down design involves creating an assembly by starting with a conceptual framework and gradually adding detail. This approach ensures that all components fit together cohesively and adhere to the overall design intent. Unlike bottom-up design, which assembles pre-made components, top-down design allows for greater control over complex assemblies.

Using Skeleton Models

Steps to utilize skeleton models:

- Create a skeleton model to serve as the foundation of your assembly.

- Define key geometries, references, and datums within the skeleton.

- Develop individual components based on the skeleton, ensuring alignment and consistency.

- Use the skeleton to manage changes, propagating updates throughout the assembly.

Inter-Part Relationships

Establishing inter-part relationships involves:

- Creating references between components to maintain proper positioning.

- Using tools like Copy Geometry to share features between parts.

- Avoiding excessive external references to prevent model complexity.

Advantages of Top-Down Design

The benefits of top-down design include:

- Global change implementation through the skeleton model.

- Improved assembly control with reduced errors and inconsistencies.

- Streamlined collaboration as team members work within a unified framework.

Customize Hardware and System Resources

Assessing Hardware Requirements

Optimizing hardware is essential for handling large assemblies:

- Ensure you have adequate RAM (at least 16GB, preferably more for very large models).

- Invest in a high-performance CPU with multiple cores and high clock speeds.

- Utilize a professional-grade graphics card certified for PTC Creo.

Optimizing System Settings

Enhance system performance by:

- Increasing virtual memory to accommodate large models.

- Closing unnecessary background applications to free up resources.

- Adjusting power settings for optimal performance if using a laptop.

PTC Creo Configuration Settings

Modify PTC Creo settings for better performance:

- Set

graphics_modein config.pro to utilize hardware acceleration. - Adjust

model_display_accuracyto balance detail and performance. - Enable data sharing options like external simplified reps to manage memory.

Regular Maintenance

Maintain optimal conditions by:

- Keeping all software and drivers up to date.

- Regularly cleaning hardware components to prevent overheating.

- Running diagnostic tools to identify and resolve performance bottlenecks.

Conclusion

Recap of Key Strategies

By implementing the strategies of utilizing simplified representations, employing lightweight components, optimizing display settings, adopting top-down design techniques, and customizing hardware resources, engineers can effectively master large assembly management in PTC Creo. Each approach addresses specific challenges, collectively contributing to a more efficient and productive design process.

The Impact on Engineering Efficiency

Effective management of large assemblies leads to improved performance, minimized load times, and streamlined workflows. These enhancements enable engineers to focus on innovation and precision, ultimately delivering higher-quality designs and meeting project deadlines with confidence.

Encouragement for Continuous Improvement

Engineers are encouraged to integrate these strategies into their daily practices and to stay informed about the latest features and updates in PTC Creo. Continuous learning and adaptation are key to maintaining efficiency and staying competitive in the ever-evolving field of design engineering.

Call to Action

We invite you to share your insights, experiences, and additional tips on managing large assemblies in PTC Creo. Your contributions can help foster a collaborative learning environment, benefiting the entire engineering community.

Also in Design News

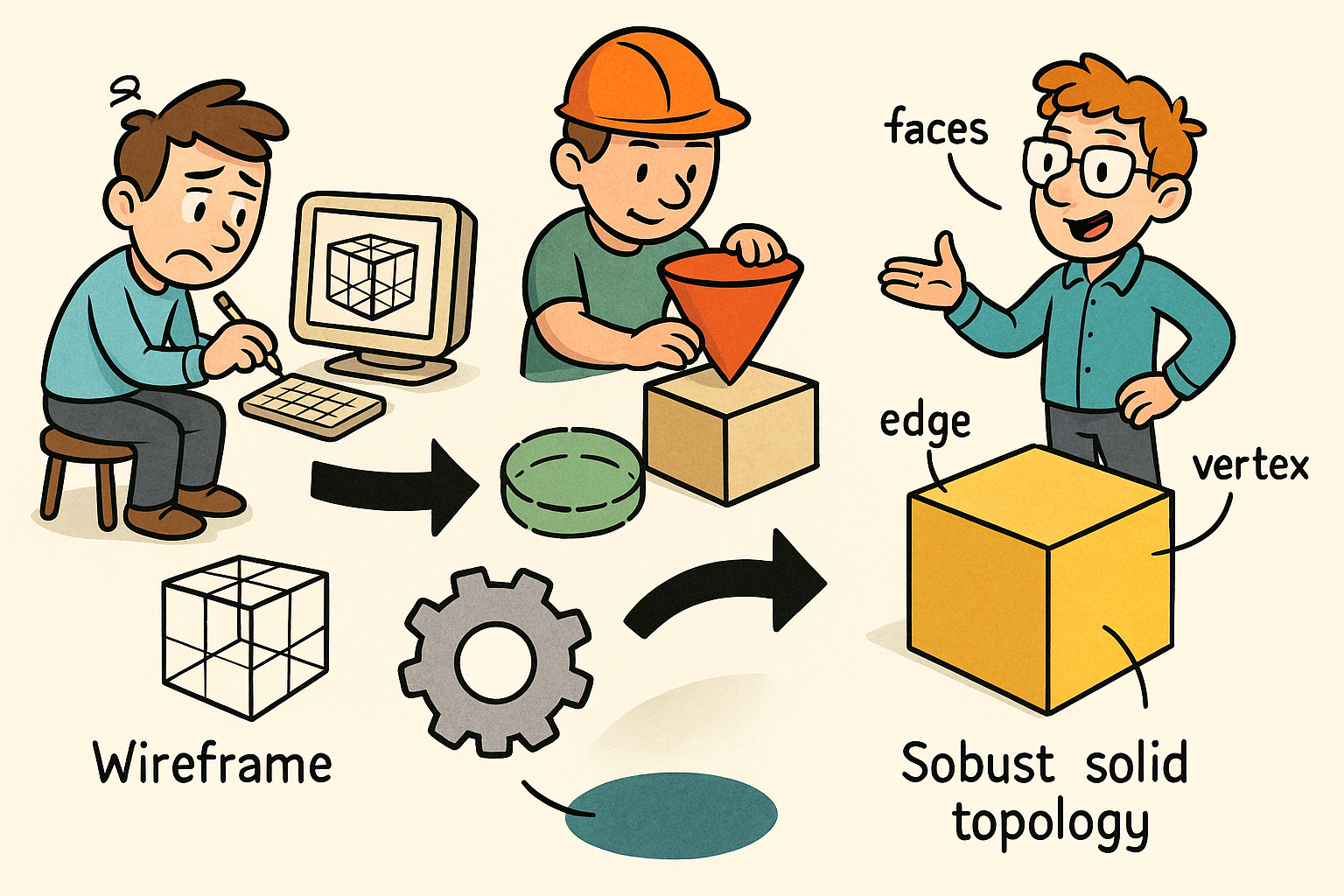

Design Software History: Why B-rep Was Invented: From Wireframe and CSG to Kernels, Topology, and Robust Solid Modeling

January 22, 2026 13 min read

Read More

Tamper-Evident Design Histories: Cryptographic Provenance, Append-Only Logs, and Deterministic Rebuilds

January 22, 2026 11 min read

Read More

Cinema 4D Tip: MatCap Shading for Rapid Form and Topology Feedback

January 22, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …