Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Rhino 3D Tip: Project vs Pull: Curve Transfer Best Practices

December 25, 2025 2 min read

Transfer curves, points, and annotations onto complex geometry with confidence by choosing the right tool: Project or Pull. Knowing when to use each delivers cleaner trims, reliable panel lines, and accurate fabrication guides.

- Project: Casts geometry in a single, consistent direction—typically the active view’s CPlane Z—onto surfaces, polysurfaces, or meshes. Best for “from-above” or “from-side” workflows where a uniform direction is essential.

- Pull: Maps geometry to the closest points on a surface, polysurface, SubD, or mesh. Ideal when you need a curve to hug the shape, even on steep areas where a directional projection would miss or distort.

When to use Project

- Creating trim lines from orthographic sketches (Top/Front/Right) for clean, predictable sections.

- Panel layouts or graphic inlays aligned to a manufacturing direction (e.g., laser marking from Top view).

- Projecting jig holes or assembly guides from a drawing plane onto a part.

When to use Pull

- Wrapping logos, seam lines, or stitching paths so they “stick” to curved bodies.

- Deriving surface-following guides for sculpting, SubD retopology, or zebra-line references.

- Transferring curves to mixed curvature areas where a single projection direction fails.

Core workflows (fast and reliable)

- Project workflow:

- Set the active view you want to project from (e.g., Top).

- Run Project → select curves/points → select target surface/polysurface/mesh.

- Keep DeleteInput=No to compare before/after and validate.

- Use Trim or Split with the result; then SimplifyCrv if needed.

- Pull workflow:

- Place your driving curves near the target geometry.

- Run Pull → select curves/points → select target.

- Inspect for tiny kinks on tight corners; use FitCrv or Rebuild if required.

- Proceed to Split/Trim or use as path guides for paneling or engraving.

Quality and predictability tips

- Decide by intent: choose Project for directional intent; choose Pull for surface-hugging intent.

- Reduce curve complexity before transfer: Rebuild or FitCrv produces cleaner, lighter results.

- Check tolerances: set appropriate Absolute tolerance in Document Properties before heavy transfers.

- Validate outcomes: use Analyze > Curve tools to find self-intersections or tiny segments after transfer.

- Meshes vs NURBS: both commands work on meshes; however, expect faceted outcomes on coarse meshes—consider QuadRemesh or refine the mesh first.

- After trimming with projected/pulled curves, run ShrinkTrimmedSrf to keep models tidy.

Troubleshooting

- Nothing appears? Switch to the view you intended and re-run Project (the direction is view-dependent).

- Unexpected splits on polysurfaces? Try Pull for closest-point mapping or pre-Join faces if applicable.

- Deformed results on steep areas? Prefer Pull, or break the curve into logical segments and transfer in parts.

Looking to expand your Rhino workflow? Explore Rhino licenses, upgrades, and plug-ins at NOVEDGE and get expert guidance. If you are new to Rhino or upgrading, see Rhino at NOVEDGE for current offers and bundles.

You can find all the Rhino products on the NOVEDGE web site at this page.

Also in Design News

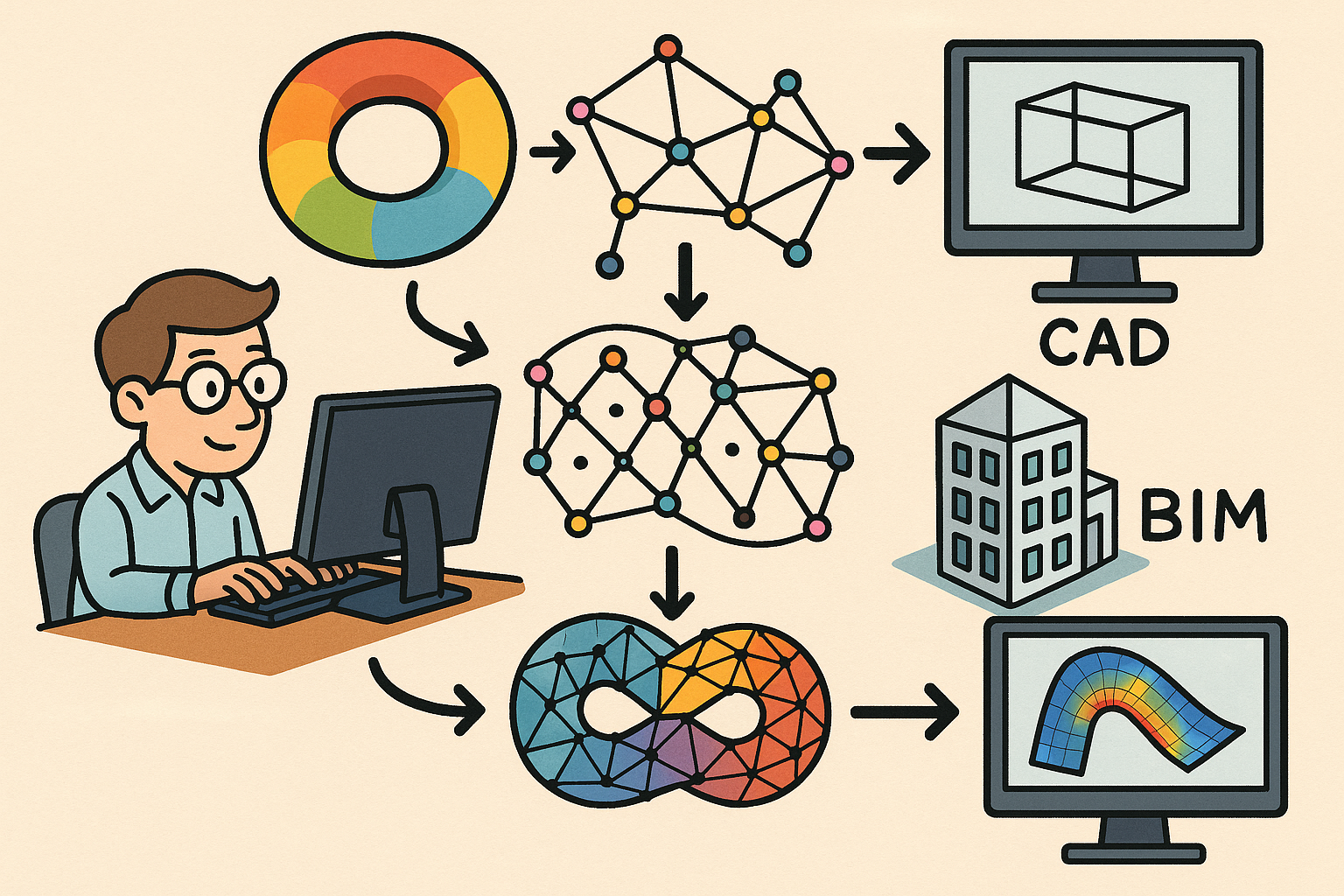

Design Software History: From Computational Topology to Design Software: Integrating TDA into CAD, BIM and CAE Workflows

December 25, 2025 10 min read

Read More

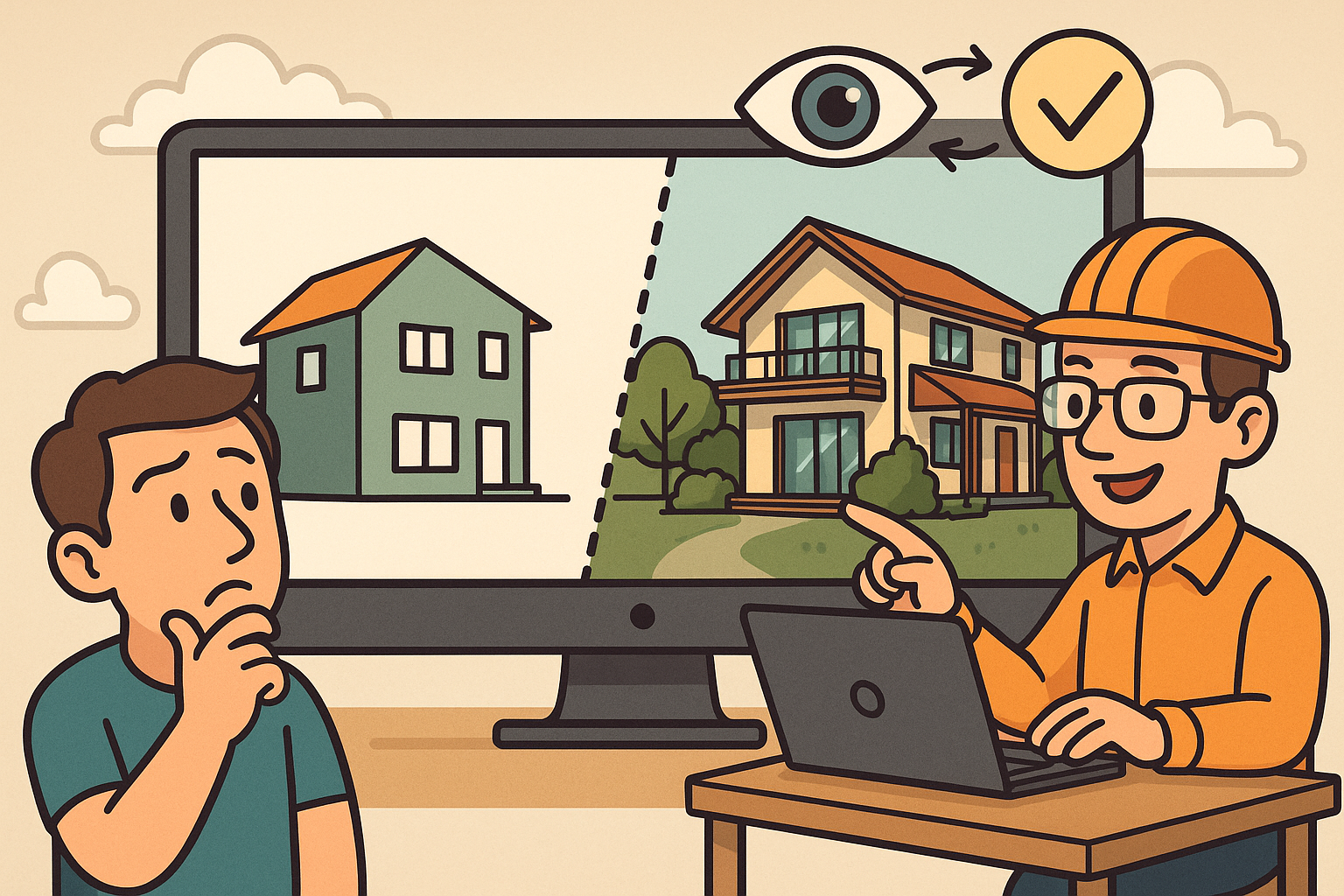

Scene-Aware LOD: Perception-Driven Fidelity for Scalable Design Visualization

December 25, 2025 12 min read

Read More

Cinema 4D Tip: Hair-to-Spline Workflow for Stylized NPR Ribbons in Cinema 4D

December 25, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …