Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Revolutionizing Product Design: Integrating Predictive Maintenance into Design Software for Enhanced Efficiency and Sustainability

July 13, 2024 3 min read

Predictive Maintenance (PdM) represents a significant evolution in the maintenance strategies associated with product design and manufacturing. Unlike traditional reactive maintenance, PdM leverages advanced technologies and data analytics to predict equipment failures before they occur, enabling proactive repairs and adjustments. This shift not only enhances the reliability and efficiency of manufacturing operations but also extends the lifespan of assets, significantly reducing the overall maintenance costs and downtime.

The integration of PdM into design software stands at the forefront of this technological evolution, offering unprecedented benefits. By embedding predictive maintenance capabilities directly into design processes, manufacturers can anticipate potential issues and design maintenance-friendly products from the outset. This approach fosters a seamless alignment between the design phase and the maintenance strategy, ensuring that products are not only optimized for performance but also for long-term sustainability and ease of maintenance.

Design Software and Predictive Maintenance

Design software plays a pivotal role in enabling predictive maintenance by providing the tools necessary to anticipate and mitigate potential failures during the design phase. This section explores several key components of this integration:

- CAD (Computer-Aided Design) tools are essential for creating detailed designs that incorporate maintenance considerations, such as ease of access for repair and replacement of components.

- Simulation software allows engineers to model how products will perform under various operating conditions, identifying areas prone to wear and tear and enabling corrective measures to be incorporated into the design.

- The integration of IoT (Internet of Things) data analysis tools facilitates real-time monitoring of product performance, providing valuable insights that can inform ongoing maintenance strategies and future design improvements.

By leveraging these tools, manufacturers can significantly enhance the reliability and efficiency of their products, reducing the frequency and severity of equipment failures.

Key Technologies Powering Predictive Maintenance in Design Software

The implementation of predictive maintenance within design software is enabled by a suite of advanced technologies:

- The Internet of Things (IoT) provides a network of sensors that collect real-time data from equipment, allowing for continuous monitoring of its condition.

- Artificial Intelligence (AI) and machine learning algorithms analyze the data collected by IoT sensors, identifying patterns that may indicate impending failures.

- Digital Twins create virtual replicas of physical assets, enabling simulations that predict how they will respond to various scenarios and stressors.

This synergistic integration of technologies not only enhances the predictive capabilities of design software but also facilitates a more holistic approach to product development and maintenance planning.

Future Trends and Challenges

The landscape of predictive maintenance and design software integration is continually evolving, driven by advancements in technology and emerging industry trends:

- The role of AI and machine learning in predictive analytics is expanding, offering more sophisticated and accurate predictive capabilities.

- Advancements in sensor technology and data processing capabilities are enhancing the ability to monitor equipment in real-time, providing richer datasets for analysis.

- Augmented reality (AR) tools are emerging as a valuable asset in maintenance planning and execution, offering intuitive visualizations of maintenance data and procedures.

Despite these advancements, the adoption of PdM in design faces several challenges, including concerns over data privacy, the need for specialized skills to interpret predictive analytics, and technological limitations that may restrict the feasibility of implementing advanced predictive maintenance strategies.

In conclusion, the integration of predictive maintenance into design software represents a significant step forward in the pursuit of sustainable, efficient, and reliable product design and manufacturing processes. As technologies continue to advance, the potential for PdM to revolutionize maintenance strategies and product design will only grow, underscoring its critical importance in the modern manufacturing landscape.

Also in Design News

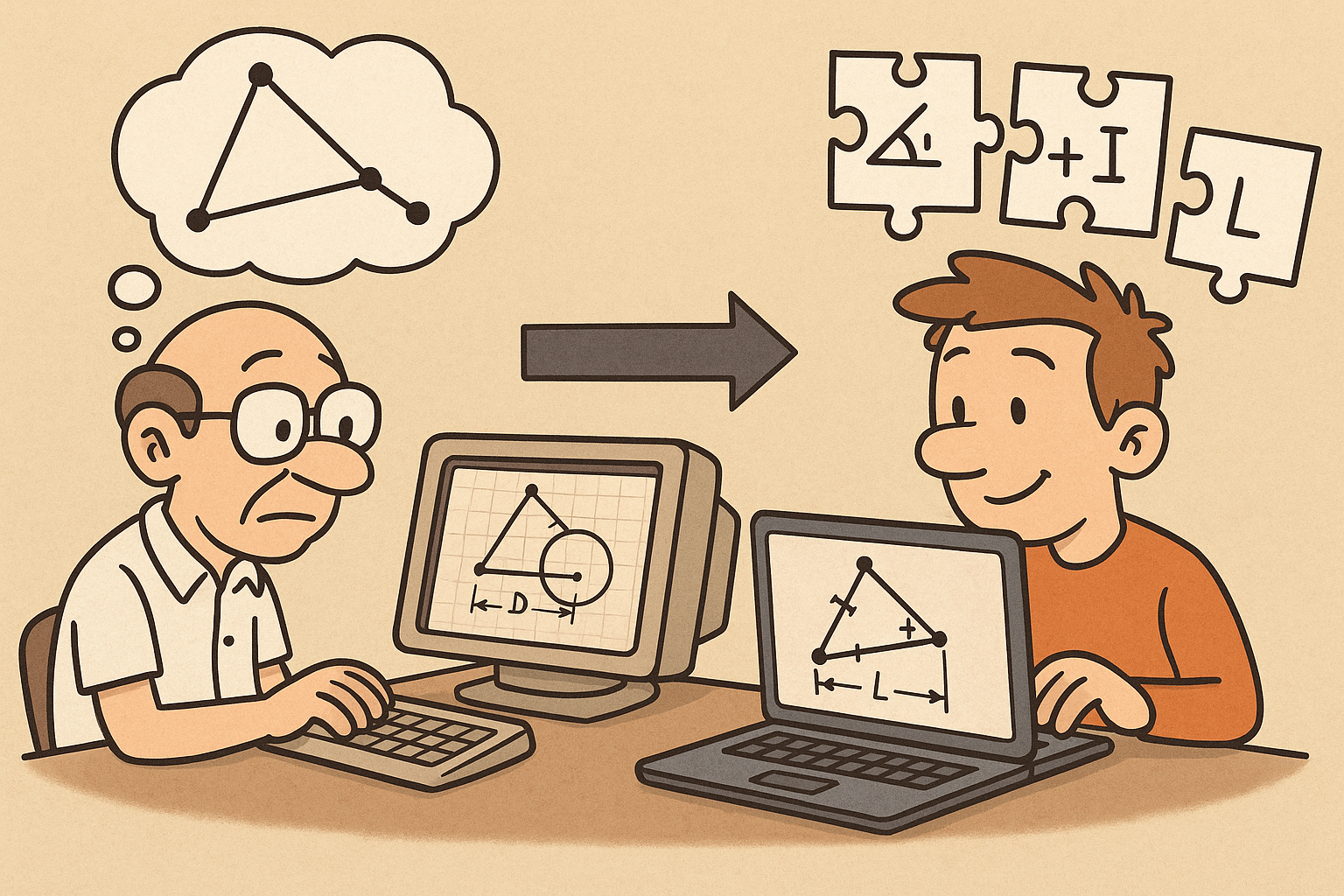

Design Software History: Constraint Solving in CAD: From Sketchpad to Modern Parametric Engines

December 31, 2025 12 min read

Read More

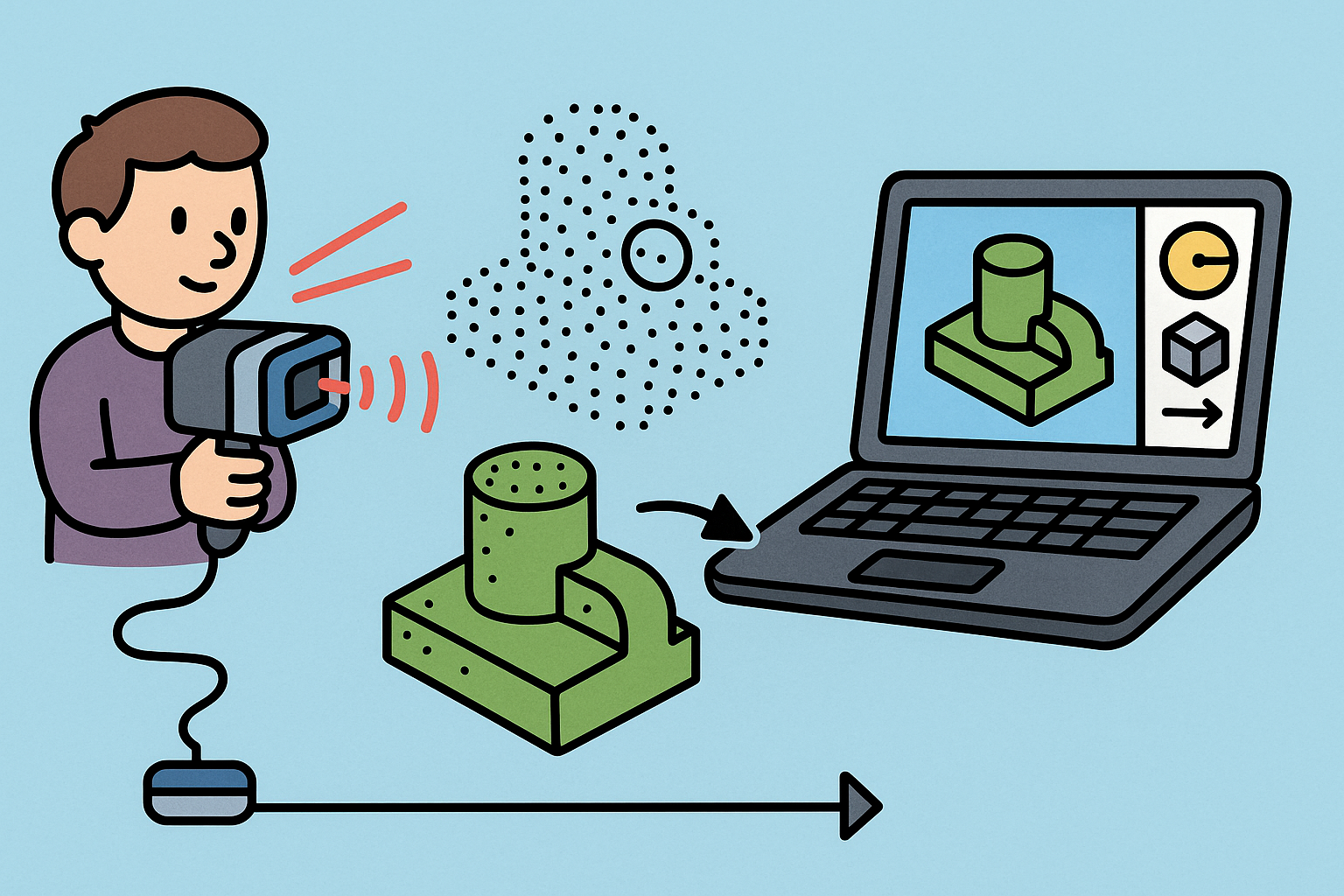

Intent-Aware Scan-to-BRep: Integrating LiDAR Point Clouds into Solid Modeling Pipelines

December 31, 2025 12 min read

Read More

Cinema 4D Tip: Hand-Painted Vertex Maps — Fast Workflow for Deformers, MoGraph, and Material Masks

December 31, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …