Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Revolutionizing CAD: Automated BOM Generation for Enhanced Precision and Efficiency

August 28, 2025 10 min read

Introduction and Context

In the realm of modern design and manufacturing, Automated Bill of Materials (BOM) generation within CAD systems has emerged as a pivotal innovation that transcends traditional manual assembly processes. Automated BOM generation is defined as the automated extraction, organization, and synthesis of complex component data directly from computer-aided design (CAD) models, thereby ensuring that every element used in a design is accurately represented in the part list. This technology plays an integral role in ensuring that current design and manufacturing workflows are both efficient and precise by negating the need for cumbersome manual data entry. It has become a cornerstone in modern product lifecycle management, bridging the critical gap between design and production. As manufacturers and designers confront increasing production complexity and faster time-to-market demands, the significance of this function in reducing errors, accelerating design validation, and streamlining production logistics is more pronounced than ever before.

Defining the Automated Process in CAD Systems

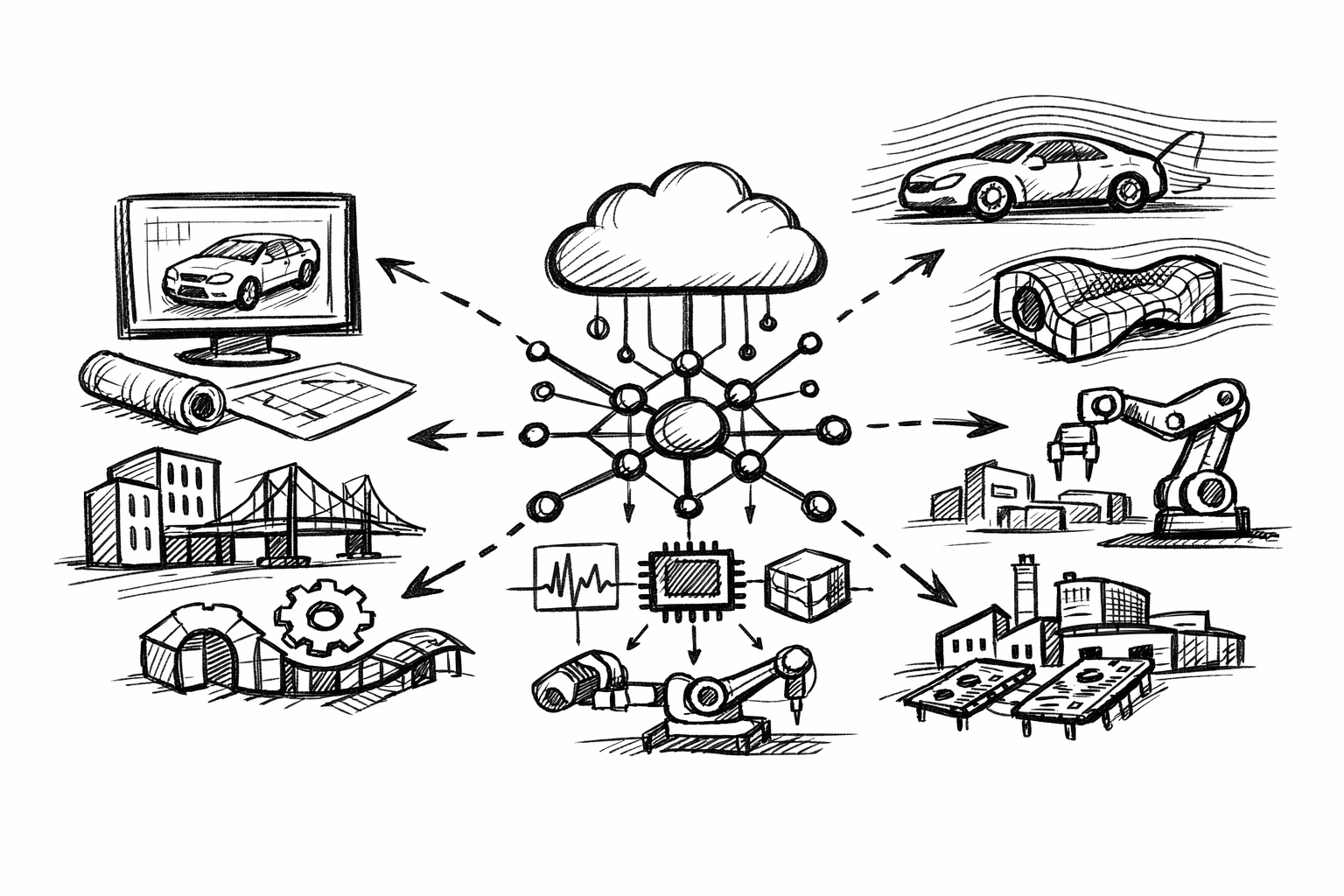

At its core, the concept of an automated BOM within a CAD system involves sophisticated data processing workflows where every component or feature in a design is automatically linked to specific entries in a comprehensive parts list. This includes not only the physical features, but also the parametric constraints and design rules that dictate component interactions. The process fundamentally hinges on capturing detailed metadata and incorporating it into an organized repository that can be further integrated into enterprise resource planning systems. This seamless translation of graphical and numerical data into actionable information for manufacturing execution systems underlines why this solution is so critical in industries ranging from automotive to aerospace. The growing emphasis on digital transformation in manufacturing further underscores the profound impact of incorporating automated solutions into traditional workflows. With the increased reliance on digital twin concepts as well as the integration of manufacturing execution systems (MES) and product lifecycle management (PLM) software, this automated approach enhances traceability, minimizes manual errors, and supports a more agile adaptation to design changes.

The Rising Demand for Automation in Product Lifecycle Management

In today’s competitive landscape, the integration of automated BOM generation represents a response to several industry challenges such as scalability, rapid product iteration, and the demand for greater design fidelity. The trend towards automation is not simply a reaction to the need for improved speed; it is also about ensuring that critical design data remains consistent and error-free across evolving manufacturing requirements. As industries increasingly pivot towards customized products and smaller production batches, the need for a robust digital backbone, capable of real-time data handling and interoperability, becomes essential. Automation not only ensures that every component is accurately documented but also supports continuous innovation by providing designers with immediate feedback on the feasibility and cost implications of their designs. In this way, automated BOM systems facilitate a smoother transition from the conceptual design phase to the manufacturing stage, ensuring that every step is informed by reliable, data-driven insights. Moreover, this process forms a critical link in the integration of CAD and PLM systems, promoting a holistic view of the product lifecycle where each change is accurately captured and communicated.

Core Technologies and Methodologies

The underlying technologies that power automated BOM generation are as advanced as they are diverse, integrating state-of-the-art algorithms, data models, and interoperability frameworks. The essence of these systems lies in their capability to intelligently extract and interpret graphical, parametric, and relational data from complex CAD models. Central to this approach is the technique of feature recognition, where software algorithms identify and categorize geometric features and design parameters, enabling the subsequent generation of a structured BOM. These methodologies are bolstered by data extraction frameworks and parametric mapping tools that help bridge the gap between detailed design elements and their corresponding entries in a BOM. Designers and engineers gain a significant advantage as the pipeline to production is streamlined through automated mapping of CAD details to structured part lists, minimizing errors and reducing the turnaround time from design to production. Such advanced methodologies are essential to ensure consistent data flow and version control, especially in large, collaborative environments where multiple iterations and modifications are the norm.

Key Algorithms and Data Models

The first pillar of this advanced system revolves around the deployment of sophisticated algorithms designed for feature recognition and parametric data extraction. These algorithms work by scanning complex CAD models to identify and correlate individual features that match predefined design templates. By doing so, the software can automatically annotate parts with metadata essential for BOM creation, such as material specifications, dimensions, and tolerance limits. This process significantly reduces the manual overhead associated with interpreting and transcribing design data into a tabulated parts list. Furthermore, data models that structure this extracted information are built to accommodate complex relationships, including hierarchical product compositions and multi-level assemblies. Developers continue to refine these models to harness both the breadth and depth of information contained within CADs, thereby ensuring that automated BOM generation is not only accurate but also scalable. Designers highly value this technology, as it transforms raw geometric data into actionable intelligence that supports both production planning and cost estimation. The use of these data models and algorithms underpins the entire process, ensuring a resilient and adaptable integration between the design environment and manufacturing execution.

Integration with CAD and PLM Systems

Another critical aspect of automated BOM generation lies in its seamless integration with existing CAD and PLM systems. This integration is achieved by developing standardized interfaces and data exchange protocols that allow smooth communication between disparate systems, aligning design processes with product lifecycle management. Strong interoperability is a prerequisite; the automated BOM systems must interpret CAD data in a manner consistent with the requirements of PLM software. This not only enables companies to maintain a single source of truth regarding product data but also facilitates a continuous feedback loop between design modifications and production planning. Several key benefits arise from such integration:

- Seamless Data Flow – Ensures that design changes are instantly captured in BOM updates.

- Improved Traceability – Enhances the tracking of design revisions and component updates.

- Efficient Collaboration – Allows multiple teams to work synchronously on evolving designs.

- Cost and Time Efficiency – Reduces manual intervention, mitigating the risk of human error.

Challenges: Accuracy, Consistency, and Version Control

While the advancements in automated BOM generation provide considerable benefits, the technology itself is not without challenges. One of the recurring concerns is guaranteeing the accuracy of BOM entries. Accuracy must be maintained across multiple design changes and iterations, each capable of introducing discrepancies if not carefully managed. Equally important is the necessity for consistency, as BOMs are often generated from a diverse array of CAD environments, each with their own unique data representations. Implementing robust version control mechanisms becomes critical in this scenario; maintaining an audit trail of changes in an evolving design is paramount. Challenges in version control typically stem from concurrent modifications by geographically dispersed teams, and the need to backtrack or merge changes without compromising data integrity requires sophisticated algorithms tailored for conflict resolution. Addressing these issues means leveraging advanced configuration management systems capable of synchronizing versioning across multiple platforms. The importance of consistent and precise BOM generation cannot be overstated, as even minor discrepancies can lead to downstream production errors, cost overruns, or supply chain disruptions. Thus, developers and system integrators continually work toward refining their methodologies to cater to these dynamic and often unpredictable variables.

Impact on Design Processes and Industry Practices

Automated BOM generation has a profound impact on design processes and industry practices, particularly in sectors where precision and speed are critical. By eliminating the need for tedious manual entry, designers and engineers can focus on creative problem-solving and innovative design solutions, all while ensuring that every detail is captured and communicated accurately. The shift from manual to automated processes brings forth multiple operational efficiencies, notably in reducing human error and expediting design iterations. As companies modernize their production lines and integrate digital solutions, the role of automated BOM systems becomes indispensable. The adoption of such technologies ultimately results in a smoother transition from the design phase to manufacturing, permitting real-time updates and connectivity between various production stages. This transformative influence is not only a technological evolution but also a paradigm change in how organizations approach product design and lifecycle management. The benefits extend to cost reduction, improved accuracy in cost estimation, and better inventory management, profoundly altering industry expectations and competitive standards.

Reduction in Manual Data Entry and Human Error

One of the most significant advantages provided by automated BOM systems is the drastic reduction in manual data entry, which historically has been a source of potential human error in engineering and design workflows. By relying on automated algorithms to parse and extract data directly from CAD models, manufacturers can minimize inconsistencies and ensure that every component and feature is accurately documented. This shift substantially reduces the opportunities for errors that stem from manual typographical corrections, data omissions, or misinterpretations of design nuances. The automation process ensures a higher degree of fidelity between the design intent and the generated BOM, which in turn minimizes downstream bottlenecks in production assembly. A further benefit is the improved speed with which design alterations are reflected in the BOM, allowing companies to manage design iterations more effectively. Additionally, automation supports enhanced collaboration across multidisciplinary teams by establishing a cohesive data environment that reconciles design specifications and production requirements. In essence, the reduction in manual data entry not only saves time but fortifies the entire production process against the inherent risks of human oversight.

Acceleration of Design Iterations and Improved Cost Estimation

The second notable benefit of leveraging automated BOM generation systems is the facilitation of accelerated design iterations. When designers can quickly update and modify their CAD models with the confidence that these changes will be automatically mirrored in the BOM, the traditional barriers to rapid prototyping diminish significantly. This improvement in iteration speed not only enhances the overall design agility but also ensures that early-stage decisions regarding component selection, material specifications, and manufacturing constraints are informed by dynamic data feedback. Enhanced cost estimation arises naturally from this process; real-time integration between design data and production parameters allows for instant recalculations of projected manufacturing costs, thereby enabling more accurate budgeting and resource planning. In many instances, automated BOM systems incorporate intelligent error-checking mechanisms, ensuring that adjustments in one part of the design cascade through all relevant documentation. This synergy between rapid iteration and accurate cost estimation is especially valuable when managing design projects that span multiple teams and require strict coordination between design modifications and the material procurement process. The additional benefits of this system are underscored by bullet points that highlight the operational advantages:

- Enhanced Productivity – Streamlined design modifications reduce downtime.

- Improved Budget Accuracy – Real-time cost recalculations based on iterative design changes.

- Robust Data Integrity – Continuous feedback loops ensure up-to-date documentation.

- Trustworthy Design Verification – Immediate validation of design modifications minimizes risk.

Future Directions and Conclusion

Looking ahead, the future of automated BOM generation in CAD systems appears poised for further evolution, driven by the rapid advances in artificial intelligence (AI), predictive analytics, and enhanced interoperability with enterprise systems. Emerging trends suggest that the next phase in this technological trajectory involves the integration of AI-powered analytics, which can not only automate BOM generation but also predict potential design flaws and cost impacts before they manifest in production. This evolution is critical in facilitating proactive adjustments to designs and preparing organizations for increasingly dynamic market demands. Additionally, the push for enhanced connectivity with ERP systems and comprehensive supply chain management tools underscores a broader industry trend toward holistic digital ecosystems. By breaking down traditional silos between design, production, and logistics, these advanced integrations promise to enable organizations to execute flawlessly coordinated production cycles, yielding faster time-to-market and augmented competitive advantages.

Integration with AI and Predictive Analytics

The integration of AI methodologies is set to revolutionize the accuracy and intelligence behind BOM generation. By leveraging machine learning algorithms to analyze historical design data, predictive analytics can forecast potential anomalies, resource shortages, or production bottlenecks well before they impact the manufacturing process. In this next phase, automated BOM systems will likely evolve to incorporate continuous learning mechanisms, where the system progressively refines its predictions based on new input data and iterative feedback. The result will be smarter BOM generation that not only captures current design details with precision but also anticipates future requirements and adjustments. Such enhancements are particularly significant in large-scale manufacturing environments where real-time decision-making is critical. Moreover, these intelligent systems will be capable of interfacing seamlessly with other enterprise-level solutions, such as ERP and supply chain management tools, making it possible to align design changes with raw material availability and production scheduling dynamically. This convergence of AI and automated BOM generation is an exciting prospect that promises to drive revolutionary changes in industrial design processes.

Enhanced Interoperability with ERP and Supply Chain Management

Alongside AI, future development in automated BOM systems focuses on deepening interoperability with ERP solutions and supply chain management. This enhanced connectivity ensures that the design process is not confined to the digital blueprint alone, but also extends to the practical realms of inventory management, procurement, and logistics. By integrating directly into ERP systems, automated BOM tools will be able to provide real-time updates on material availability, lead times, and cost fluctuations, which are crucial for decision-makers across the product lifecycle. The benefits of such seamless interconnectivity include not only accelerated product throughput but also minimized production downtime and more effective contingency planning. This advanced networking of systems allows for a more holistic view of the product journey—from initial design conception to final assembly and distribution. As different modules within a manufacturing ecosystem become increasingly interconnected, the implementation of a unified data strategy becomes essential. Organizations that successfully implement these strategies can expect a robust, agile infrastructure that minimizes disruptions, incorporates automated risk management protocols, and fortifies the entire production process against the uncertainties of global supply chain fluctuations.

Final Reflections and Roadmap for Future Innovations

In conclusion, the transformative impact of automated BOM generation systems in CAD environments represents a significant milestone in the evolution of design software and manufacturing workflows. The advantages are multifaceted, spanning from significant reductions in manual labor and human error to enhanced agility in design validation and cost estimation. The future holds promise as integration of advanced AI techniques and predictive analytics paves the way for even more intelligent and autonomous design ecosystems. This future roadmap is expected to focus on developing systems that are not only more accurate and interconnected but are also capable of learning and adapting in real-time, ultimately providing a competitive edge in today’s fast-paced industrial landscape. As manufacturers continue to embrace digital transformation, the value of robust, interconnected automated BOM systems will only continue to grow. Key takeaways from this discussion include the necessity for ongoing innovation in algorithm design, the critical importance of seamless system integration, and the ever-increasing role of AI in pushing the boundaries of what is possible. Ultimately, the drive towards smarter BOM generation technologies will catalyze further advancements in how products are designed, managed, and produced, thereby charting a course for more dynamic, responsive, and efficient operational models in the years ahead.

Also in Design News

Beyond CAD Files: Unified Design Graphs for Simulation-Driven, Manufacturable Digital Threads

March 06, 2026 11 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …