Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Integrating Computational Fluid Dynamics in Early Design: Enhancing Accuracy and Efficiency Across Industries

November 06, 2024 5 min read

Introduction

In the ever-evolving landscape of design and engineering, Computational Fluid Dynamics (CFD) has emerged as a pivotal tool that transforms the way we approach complex projects. CFD, at its core, allows designers and engineers to simulate and analyze fluid flow and heat transfer phenomena within virtual environments. This capability is not just a technological advancement; it's a fundamental shift that enhances accuracy, efficiency, and innovation across various sectors. Embracing CFD in the early phases of design is becoming increasingly crucial, especially in industries such as architecture, automotive, and aerospace, where fluid dynamics play a significant role. By integrating CFD from the outset, professionals can anticipate challenges, optimize designs, and reduce the reliance on costly physical prototypes, thereby streamlining the entire development process.

Understanding CFD and Its Applications

Computational Fluid Dynamics is a branch of fluid mechanics that utilizes numerical analysis and data structures to solve and analyze problems involving fluid flows. By employing algorithms and computational resources, CFD provides a detailed visualization and quantification of fluid behavior within a given system. The core principles revolve around solving the Navier-Stokes equations, which describe the motion of fluid substances. This mathematical approach enables the simulation of interactions between liquids and gases with surfaces, giving invaluable insights into real-world scenarios.

CFD's versatility makes it indispensable in various industries. In architecture, for instance, CFD aids in wind load analysis and natural ventilation studies, ensuring that buildings can withstand environmental forces while maintaining occupant comfort. Architects leverage CFD to simulate how wind interacts with structures, allowing for designs that optimize airflow and reduce turbulence around buildings.

In the automotive industry, CFD is crucial for aerodynamic optimization and thermal management. Engineers use it to minimize drag, enhance vehicle stability, and improve fuel efficiency. By simulating airflow over a car's body, designers can identify areas of high resistance and adjust shapes accordingly. Additionally, CFD helps in managing engine cooling systems by analyzing heat transfer and fluid flow within components.

The aerospace sector relies heavily on CFD for flight dynamics and engine performance. It enables the simulation of airflows around aircraft, predicting lift, drag, and overall aerodynamic efficiency. CFD helps in designing wings, fuselage, and propulsion systems that meet stringent safety and performance standards.

Integrating CFD early in the design process offers several benefits:

- Enhances design accuracy: Early simulations identify potential issues before they become costly problems.

- Reduces time and cost: Less reliance on physical prototypes means faster development cycles and lower expenses.

Tools and Techniques for CFD Integration

The successful integration of CFD into early design phases depends significantly on the tools and techniques employed. A variety of CFD software options are available, each with unique features catering to different industry needs. Popular tools include ANSYS Fluent, known for its comprehensive modeling capabilities; OpenFOAM, an open-source platform offering flexibility and customization; and COMSOL Multiphysics, which provides integrated simulation solutions for coupled physics problems.

To ensure seamless integration, it's essential to focus on CAD software compatibility. Utilizing direct tools for geometry manipulation allows for smooth transitions between design and simulation. Software that supports native CAD formats minimizes the loss of data fidelity and reduces the need for remodeling. Automation scripts play a vital role in streamlining workflows, enabling repetitive tasks to be performed efficiently. By automating mesh generation, boundary condition application, and result extraction, designers can focus more on analysis and less on setup.

Techniques for effective CFD integration include:

- Parametric modeling: Allows for quick adjustments of design variables and immediate assessment of their impact on performance.

- Multi-disciplinary optimization: Integrates CFD with other simulation disciplines (like structural analysis) for a holistic design approach.

Challenges and Solutions in Early Integration

While integrating CFD into early design phases offers clear advantages, it also presents several challenges. One of the most common hurdles is the initial learning curve associated with CFD tools. These software packages can be complex, requiring a deep understanding of fluid mechanics and numerical methods. Designers may find it daunting to set up simulations accurately and interpret the results effectively.

The complexity of simulation setup is another significant challenge. Defining appropriate boundary conditions, selecting the right turbulence models, and ensuring mesh quality are critical steps that demand expertise. Missteps in these areas can lead to inaccurate results, undermining the benefits of early CFD integration.

Balancing computational resources against design timelines poses additional difficulties. High-fidelity simulations can be computationally intensive, consuming significant time and processing power. In fast-paced development cycles, waiting for simulations to complete can hinder progress and delay decision-making.

To address these challenges, several solutions can be implemented:

- Training and workshops: Investing in the professional development of design teams ensures that members are proficient with CFD tools and methodologies.

- Establishing multidisciplinary teams: Including CFD specialists within design teams promotes knowledge sharing and collaborative problem-solving.

- Leveraging cloud-based CFD tools: Utilizing cloud computing resources provides enhanced computational power and accessibility, allowing for more complex simulations without the need for significant local hardware investments.

Conclusion

Integrating Computational Fluid Dynamics analysis into the early stages of the design process is more than a technical enhancement—it's a strategic move that aligns with the demands of modern engineering and design practices. The early adoption of CFD leads to better-informed decisions, optimized designs, and a reduction in time and costs associated with development. As simulation technology continues to advance, the role of CFD is set to become even more significant.

Looking ahead, emerging technologies such as artificial intelligence and machine learning are poised to enhance CFD capabilities further. These advancements will enable more efficient simulations, automatic recognition of optimal solutions, and even predictive design adjustments based on vast datasets. The integration of AI will help in handling complex simulations with greater speed and accuracy, making CFD an even more powerful tool.

It's imperative for designers and engineers to embrace CFD as a fundamental component of their toolkit. By doing so, they position themselves at the forefront of innovation, equipped to tackle the challenges of today's projects and those of the future. The collaborative use of CFD fosters a proactive approach to design, where potential issues are addressed before they materialize, leading to more innovative and efficient solutions. Now is the time to integrate CFD into your design processes and unlock the full potential of your projects.

Also in Design News

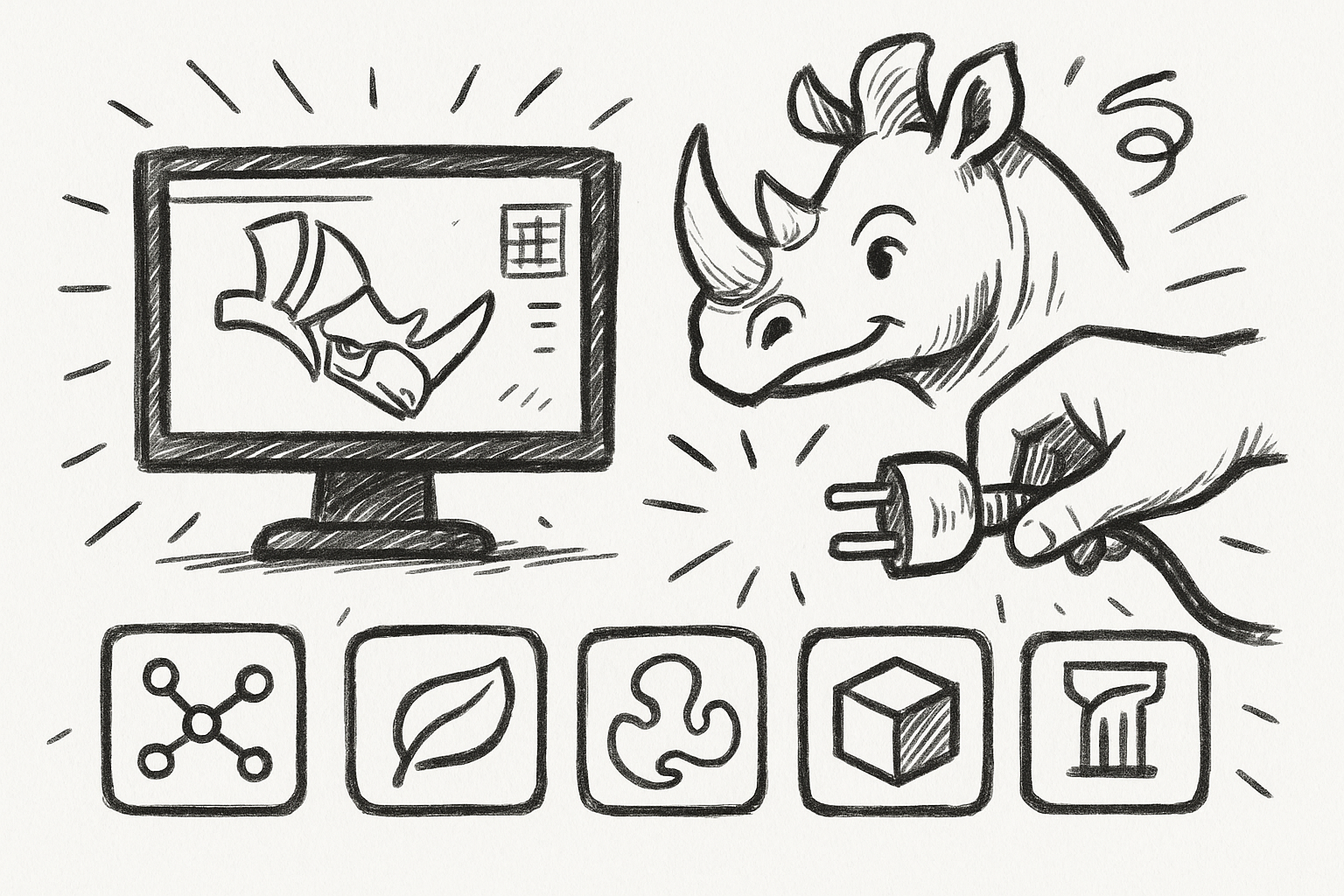

Mastering Rhino: 5 Essential Plug-Ins to Elevate Your Design Workflow

September 16, 2025 6 min read

Read More

"Revolutionizing Urban Planning: Unleashing SketchUp for Rapid, Data-Driven City Design"

September 16, 2025 5 min read

Read More

Cinema 4D Tip: Integrating VDB Format for Advanced Volumetric Workflows in Cinema 4D

September 16, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …