Your Cart is Empty

Parametric design represents a paradigm shift in the realm of custom manufacturing, introducing a level of flexibility and efficiency previously unattainable with traditional design methodologies. Unlike conventional approaches that rely heavily on manual modifications, parametric design leverages algorithms and rules to automatically adjust and optimize design parameters in response to changes. This inherent flexibility facilitates the creation of complex, custom-fitted products with relative ease, ushering in a new era of manufacturing that is both more dynamic and responsive.

Key Advantages of Parametric Design for Manufacturers

- Automation and Efficiency: Parametric design automates the generation of design variations, significantly reducing the time required for manual adjustments and, consequently, minimizing human error.

- Customization and Scalability: It offers unmatched efficiency in tailoring designs to meet specific client requirements, thereby supporting mass customization and scalable production processes.

- Cost Reduction and Speed: By streamlining the design process, parametric design significantly cuts down on both development costs and time to market, providing a competitive edge in rapidly changing markets.

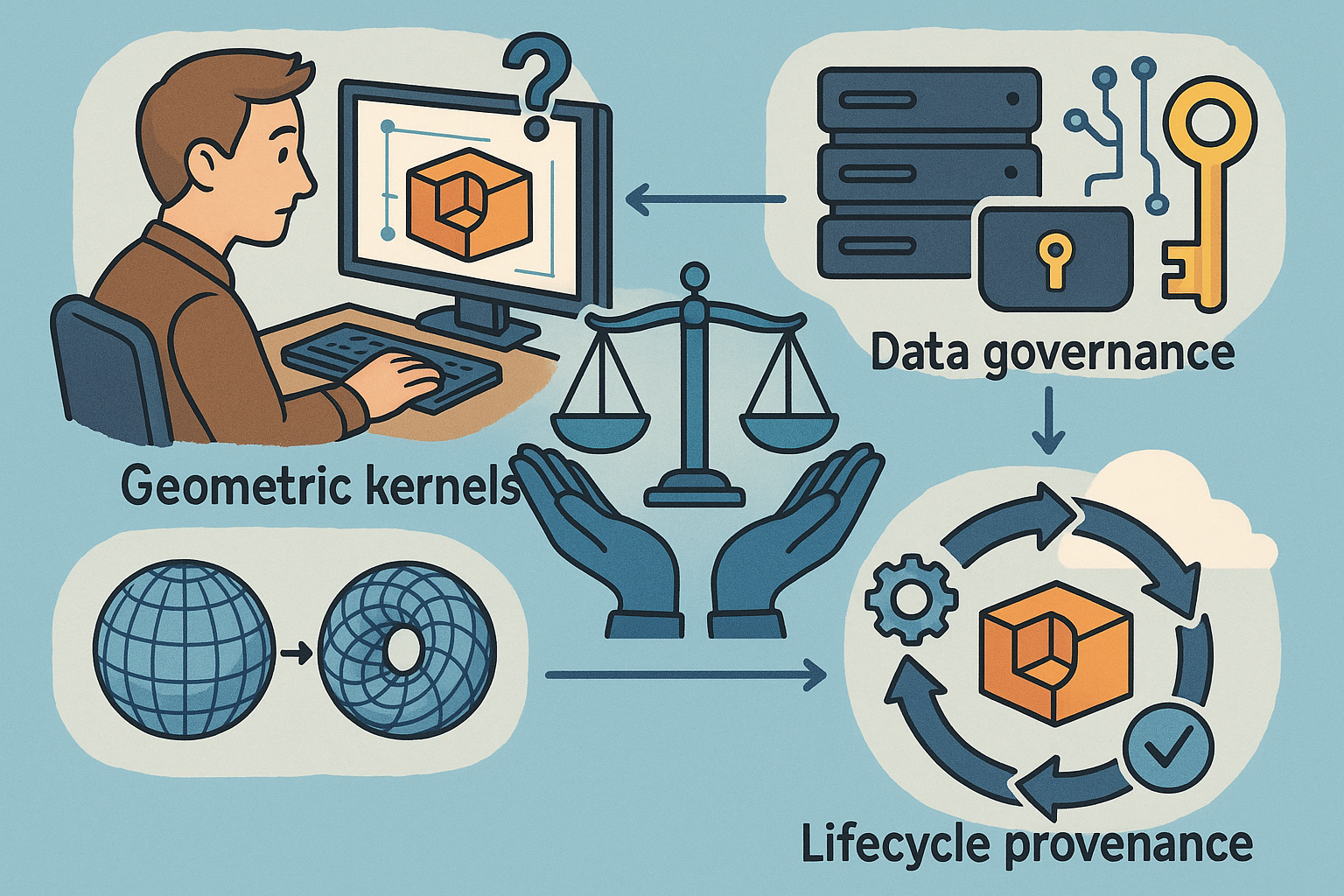

- Integration with Other Technologies: This design approach seamlessly integrates with cutting-edge manufacturing technologies such as additive manufacturing and AI, further enhancing production capabilities and enabling the creation of innovative products.

Real-World Applications and Case Studies

In the aerospace and automotive industries, parametric design plays a crucial role in developing complex, lightweight components that adhere to stringent performance and safety standards. The architectural and construction sectors utilize parametric design to conceptualize and implement innovative structures, optimizing material usage and environmental impact. Additionally, the versatility of parametric design has found its way into the consumer goods industry, enabling the creation of highly customizable products that cater to the unique preferences of individual consumers.

Challenges and Future Directions

The adoption of parametric design is not without its challenges. The learning curve and accessibility of advanced parametric design software can pose significant barriers to entry for new users. Furthermore, interoperability with existing systems remains a persistent issue, as the seamless exchange of data between different software platforms is crucial for efficient workflow. Looking ahead, the future of parametric design is poised for remarkable evolution, with AI integration promising smarter, more intuitive design systems and the continuous advancement of manufacturing technologies opening new avenues for innovation.