Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: The Evolution of Fusion 360: Pioneering Unified Product Development

July 20, 2024 4 min read

The Genesis and Evolution of Fusion 360

Origins

Fusion 360 emerged as a significant milestone in the realm of design software, brought to life by Autodesk. This came as a response to the growing demand for integrated tools that cater to both design and manufacturing processes. During the transition from traditional CAD software to cloud-based solutions, Autodesk recognized the need for a more unified approach. This period marked a change from isolated software applications to comprehensive platforms capable of covering the entire product development lifecycle.

Development Milestones

The initial launch of Fusion 360 was a crucial moment, as it set the foundation for what would become a revolutionary tool in the industry. Early versions of Fusion 360 introduced several key features that have since evolved, significantly enhancing the software’s capabilities. Over the years, features such as parametric modeling, generative design, and CAM integration have been pivotal in cementing Fusion 360's position as a leader in design and manufacturing software.

Core Technologies and Innovations

Unified Platform

One of Fusion 360’s standout features is its unified platform, which seamlessly integrates CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), CAE (Computer-Aided Engineering), and PCB (Printed Circuit Board) design processes. This comprehensive integration provides numerous advantages:

- Streamlined workflows by eliminating the need to switch between different software tools.

- Enhanced collaboration as all team members can work within a single environment.

- Reduced errors and inconsistencies since all aspects of product development are interconnected.

Cloud-Based Architecture

Fusion 360 leverages the power of cloud computing to offer significant benefits. These include improved collaboration, as teams can work together in real-time from different locations. The cloud-based architecture also ensures that storage and computational power are scalable and accessible:

- Collaboration: Real-time updates and file sharing improve teamwork and efficiency.

- Storage and Computational Power: Cloud resources allow for handling larger files and more complex computations without local hardware limitations.

Security and accessibility are critical concerns in cloud computing. Autodesk addresses these concerns through robust security protocols and encryption, ensuring data safety and providing users with reliable access to their projects from any location.

Advanced Simulation and Analysis

Fusion 360 incorporates advanced simulation and analysis tools, such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). These tools play a crucial role in product verification and validation, allowing designers to test and optimize their designs before manufacturing:

- FEA: Helps in understanding the structural integrity of designs under various conditions.

- CFD: Enables the analysis of fluid flow and thermal dynamics within a product.

These simulation capabilities help in reducing the need for physical prototypes, thereby saving time and costs in the product development process.

Impact on the Design and Manufacturing Industries

Democratizing Design

Fusion 360 has played a significant role in democratizing design by providing powerful tools to startups, small businesses, and individual designers. This accessibility empowers smaller entities to compete with larger companies by leveraging advanced design and manufacturing capabilities.

Collaborative Design and Teamwork

The real-time collaboration features of Fusion 360 have revolutionized teamwork in the design and manufacturing industries. These features facilitate global collaboration, enabling teams to work together seamlessly regardless of geographical barriers. User feedback highlights the positive impact of these collaborative tools on productivity and innovation.

Additive and Subtractive Manufacturing Integration

Fusion 360 supports both 3D printing (additive manufacturing) and CNC machining (subtractive manufacturing), making it a versatile tool for various manufacturing processes. This support has contributed to the rise of additive manufacturing and rapid prototyping, allowing for faster iteration and development cycles.

The Future of Fusion 360 and Its Ecosystem

Ongoing and Planned Improvements

Autodesk continues to enhance Fusion 360 with new features and improvements. Upcoming updates, influenced by user feedback, aim to further streamline workflows and introduce innovative capabilities. This user-driven development approach ensures that the software evolves to meet the changing needs of its users.

Integration with Emerging Technologies

The potential integration of Fusion 360 with emerging technologies such as AI and machine learning promises to revolutionize design processes. These technologies can enable smarter, more efficient design workflows. Additionally, exploring AR/VR for immersive design and visualization experiences could further enhance the way designers interact with their projects.

Market Position and Competitors

Fusion 360 occupies a unique position in the competitive landscape of CAD software. It stands out by offering a unified platform that integrates multiple design and manufacturing processes. However, it faces competition from other popular platforms like SolidWorks, CATIA, and Onshape. Each of these platforms has its strengths, but Fusion 360’s comprehensive approach and cloud-based architecture provide distinct advantages.

Conclusion

In summary, Fusion 360 has had a transformative impact on the product development lifecycle, from its genesis at Autodesk to its current role as a leading design software platform. Its innovative features, cloud-based architecture, and commitment to user-driven development have set it apart in the industry. Looking ahead, the integration with emerging technologies and continuous improvements will likely shape the future trajectory of design software, inspired by the groundbreaking advancements of Fusion 360.

Also in Design News

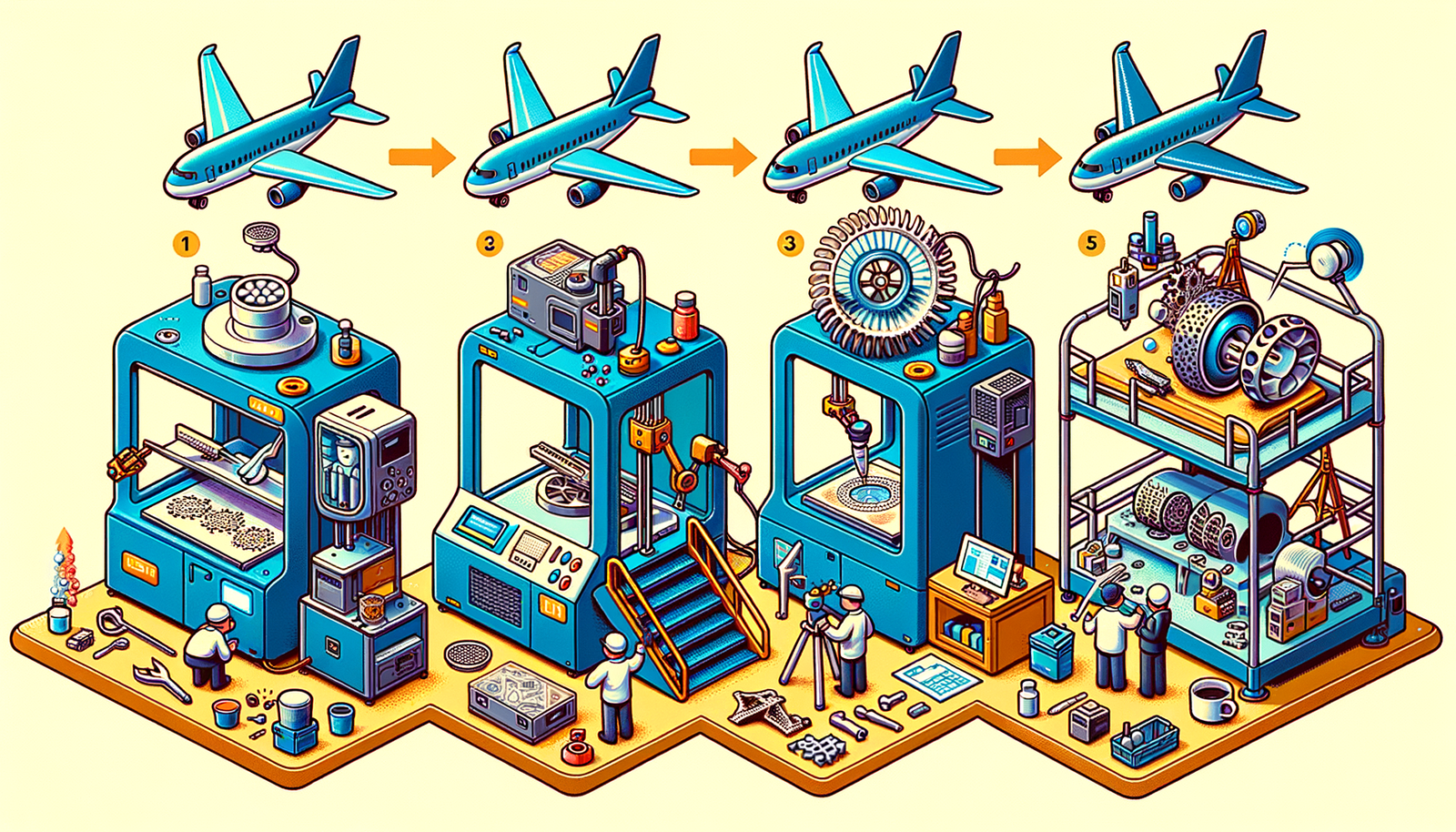

Design Software History: The Evolution of 3D Printing in Aerospace: From Prototyping to Production

November 27, 2024 7 min read

Read More

Cinema 4D Tip: Optimizing Workflow with Team Render in Cinema 4D

November 27, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …