Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Exploring the Impact of Augmented Reality in Design and Manufacturing

July 05, 2024 2 min read

Introduction to Augmented Reality (AR) in Design

Augmented Reality (AR) technology overlays digital information onto the real world, enhancing our perception of our surroundings. Its application in design and manufacturing marks a significant evolution from traditional methods. Initially conceptualized in the early 1990s, AR's journey into mainstream design practices showcases an impressive trajectory of technological advancement. Today, AR stands as a pivotal innovation in design processes, offering unparalleled benefits. The incorporation of AR in maintenance and assembly instructions exemplifies its value, significantly enhancing efficiency, accuracy, and comprehensibility.

AR for Assembly Instructions

AR transforms assembly instructions, facilitating a more interactive and effective learning experience. By superimposing digital images and information onto physical objects, it provides:

- Visualization of complex assembly processes in real-time, allowing users to understand the spatial relationships and mechanics of assembly parts intuitively.

- Interactive guides and step-by-step overlay instructions, which reduce cognitive load and guide the assembler through each phase of the process seamlessly.

- A significant reduction of errors and time spent on assembling products, directly impacting productivity and operational efficiency.

While specific case studies are not discussed, various industries, including automotive and aerospace, have reported substantial improvements in assembly efficiency and accuracy through the adoption of AR technology.++p>

AR for Maintenance Operations

In the realm of maintenance and repair, AR provides tools that revolutionize traditional practices:

- Enhanced diagnostics through AR interfaces enable maintenance staff to see through components and visualize the problem areas with overlaid digital information.

- Remote assistance capabilities allow experts to guide on-site personnel through complex maintenance operations, bridging geographical gaps and expediting problem resolution.

- The technology ensures increased safety and efficiency for maintenance personnel, mitigating risks by providing real-time, accurate information.

Industries such as energy, healthcare, and consumer electronics are already reaping the benefits of AR for maintenance operations, demonstrating its broad applicability and effectiveness.

Challenges and Future Directions

Despite its considerable advantages, implementing AR in design and manufacturing is not without challenges. These include:

- Hardware requirements and limitations, such as the need for specialized AR glasses or devices, which can be cost-prohibitive.

- Software compatibility and integration issues, requiring significant investment in developing or adapting existing systems to support AR functionality.

- User adoption and training needs, as the workforce must be equipped with the skills to leverage AR technology effectively.

The future of AR in design software looks promising, with several trends indicating its growing influence:

- Advancements in AR wearables and mobile devices are expected to enhance accessibility and usability, broadening AR's application in various fields.

- The potential for AI integration to offer predictive maintenance and assembly guidance, further enhancing operational efficiency and reducing downtime.

- AR's role in facilitating remote work and global collaboration in design and manufacturing projects, enabling real-time interaction and consultation across distances.

As these trends continue to evolve, AR is poised to redefine the paradigms of design and manufacturing, offering a glimpse into a future where digital and physical realms merge seamlessly.

Also in Design News

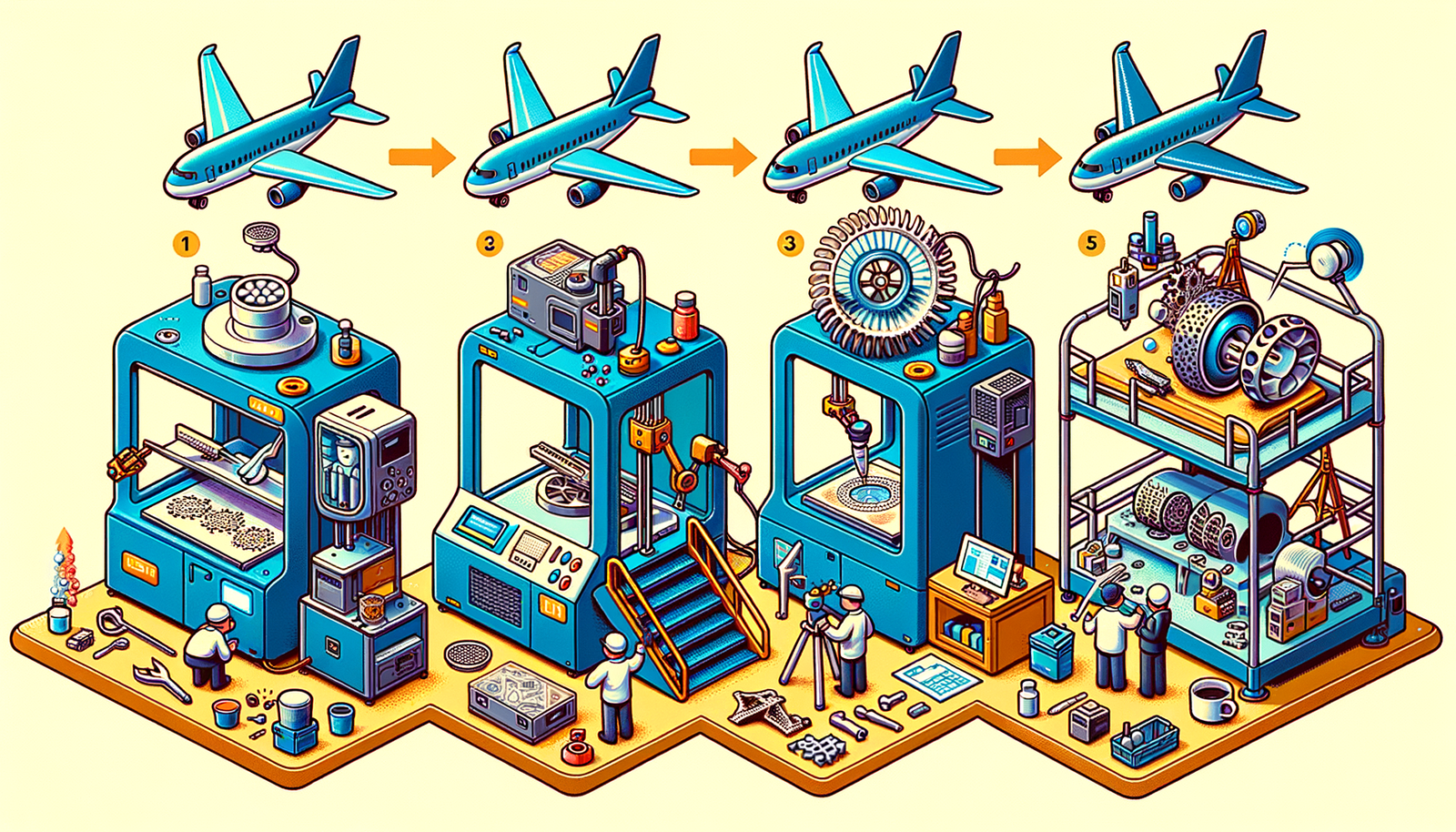

Design Software History: The Evolution of 3D Printing in Aerospace: From Prototyping to Production

November 27, 2024 7 min read

Read More

Cinema 4D Tip: Optimizing Workflow with Team Render in Cinema 4D

November 27, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …