Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Exploring the Future of Design: How Advanced Software is Revolutionizing Material Selection and Innovation

July 31, 2024 2 min read

Introduction to Materials in Design

The importance of materials in design projects cannot be overstated, serving as the foundation upon which all engineering and product development is built. From the ancient use of stone and wood to the modern exploitation of polymers and composites, the evolution of materials has continually propelled the boundaries of design and manufacturing forward. In this context, the advent of sophisticated software for material selection and innovation has become a game-changer, enabling designers and engineers to push the envelope of what's possible in creating new products.

Software Tools for Material Selection and Analysis

Today's landscape of material selection is vastly improved by a suite of software tools designed to assist in this complex decision-making process. Tools such as CES Selector and Granta Design stand out for their comprehensive databases of material properties, which include mechanical, thermal, and ecological characteristics to aid in making informed decisions. These software solutions offer powerful features, including:

- Environmental impact analysis to evaluate a material's sustainability.

- Compatibility checks between different materials to ensure product integrity.

Through detailed analysis and comparison features, these software tools facilitate a more streamlined approach to material selection, one that is integral to successful product design and engineering.

Advancements in Material Simulation Software

The role of simulation software, such as Autodesk Moldflow and COMSOL Multiphysics, in material innovation cannot be understated. These advanced platforms allow designers and engineers to predict how materials will behave under an array of conditions, thus significantly reducing the need for physical prototypes. The benefits of incorporating simulation software into the design process include:

- Considerable reductions in prototyping costs.

- Accelerated time-to-market for new products.

Moreover, simulation software plays a critical role in the development of new materials and the exploration of innovative applications, pushing the boundaries of what's possible in product and process design.

Emerging Trends and Future Directions

The landscape of material innovation is continually evolving, with software playing a pivotal role in unlocking new possibilities. Noteworthy among emerging trends are the development of bio-based materials and smart materials, which promise to revolutionize product design with their unique properties and capabilities. As the industry moves forward, the future of design software lies in its ability to support sustainable and innovative material choices, fostering a new era of design that prioritizes ecological responsibility alongside technological advancement.

Looking ahead, we can anticipate that ongoing advancements in software capabilities will further transform the process of material selection and application across various industries. The vision for the future is one where software not only aids in the selection of materials but also in the creation of entirely new materials, offering unprecedented opportunities for innovation in product design and engineering.

Also in Design News

Design Software History: Handbooks to Hyperscale: The Evolution of Materials Data, PLM and the Digital Thread

February 05, 2026 12 min read

Read More

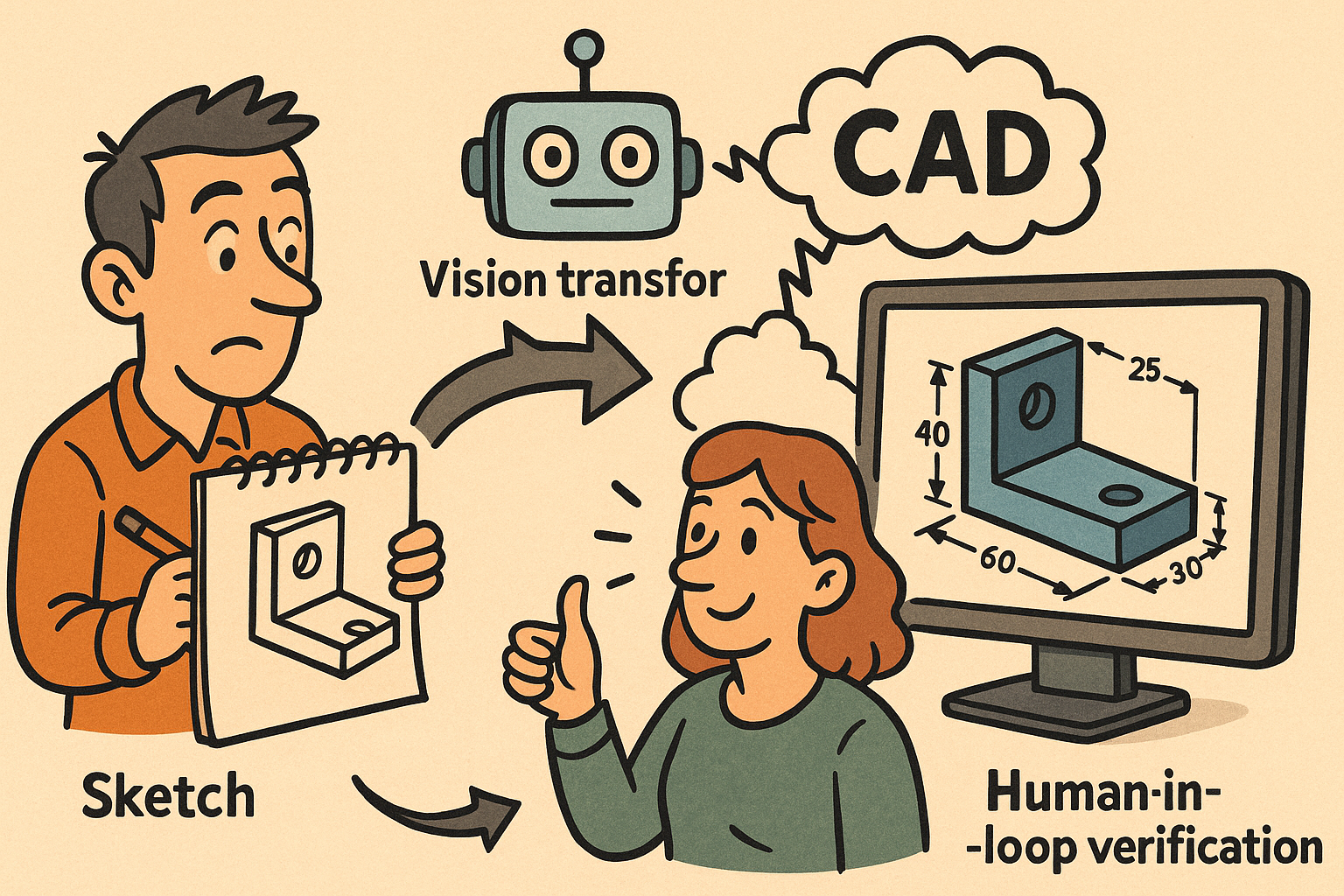

Sketch-to-CAD: Preserving Parametric Design Intent with Vision Transformers, LLM-Orchestrated CAD DSLs, and Human-in-the-Loop Verification

February 05, 2026 10 min read

Read More

Cinema 4D Tip: Scene‑Referred Color Grading Workflow with ACES and 32‑bit EXR

February 05, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …