Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: The Evolution of Fusion 360: Transforming Integrated CAD/CAM Solutions

August 16, 2024 4 min read

Introduction to Fusion 360

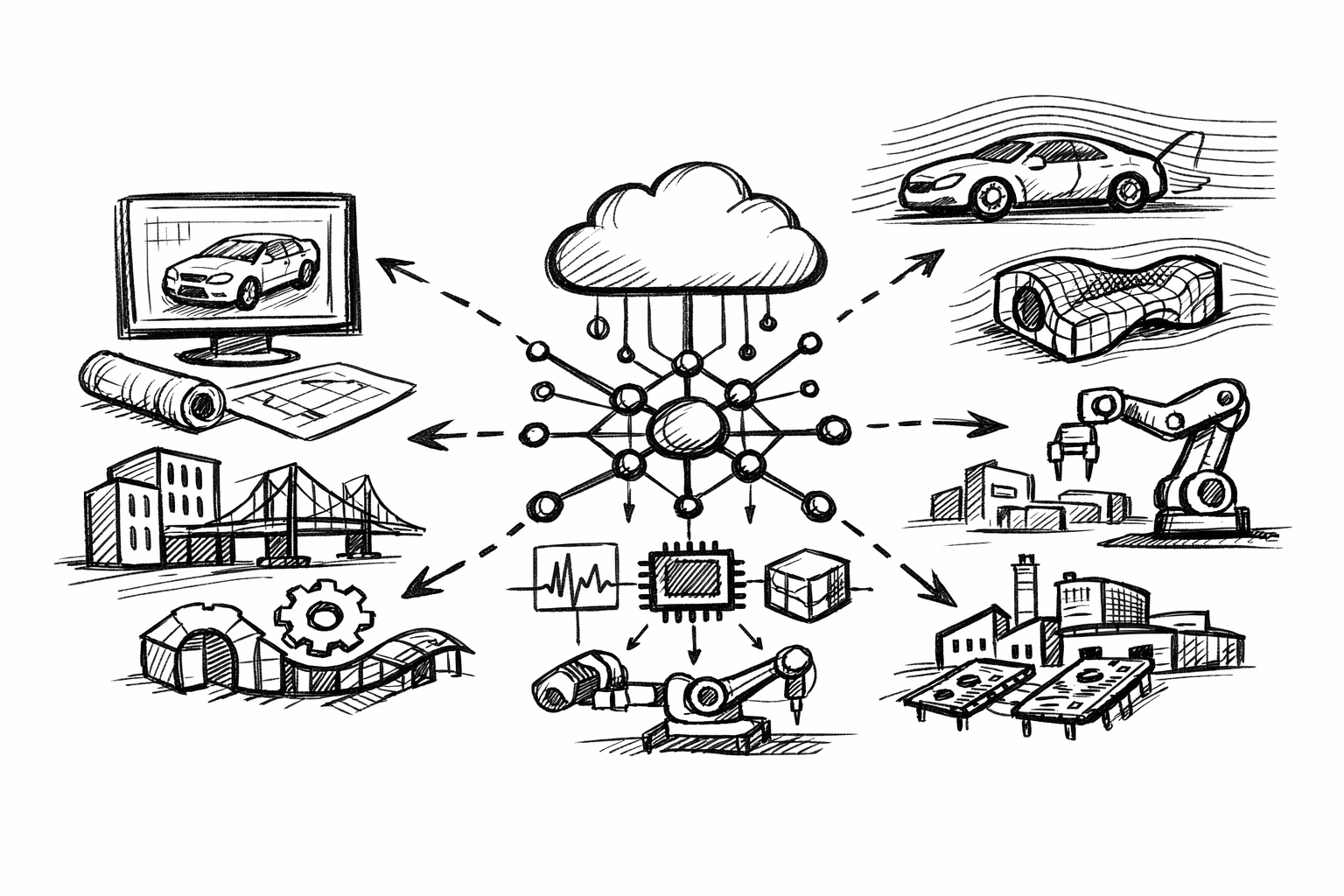

Fusion 360 is a comprehensive 3D CAD, CAM, and CAE tool developed by Autodesk. It stands out due to its integrated approach, blending design, engineering, and manufacturing workflows within a single platform. This integration allows users to go from concept to production seamlessly, enhancing efficiency and collaboration. The importance of integrated CAD/CAM solutions in the modern design and manufacturing landscape cannot be overstated, as they streamline processes, reduce errors, and expedite time-to-market.

Before the advent of Fusion 360, the landscape of CAD/CAM software was fragmented. Design and manufacturing processes often required multiple software tools, leading to inefficiencies and compatibility issues. Market analysis revealed a critical need for a more cohesive solution that could unify these disparate workflows, ultimately leading to the development of Fusion 360.

The Genesis of Fusion 360

Founding and Development

The inception of Fusion 360 can be traced back to the early 2010s, spearheaded by Autodesk, a company already renowned for its contributions to design software. Key figures in the development include Carl Bass, then CEO of Autodesk, and Jeff Kowalski, Chief Technology Officer. Their vision was to create a tool that not only addressed the existing gaps in the market but also leveraged emerging technologies.

The initial development phase began around 2011, with a public beta version released in 2012. The official launch of Fusion 360 occurred in 2013, marking a significant milestone in the CAD/CAM industry. The early goals of the software focused on creating an intuitive user experience, robust functionality, and fostering collaborative design.

Technological Innovations

Fusion 360 introduced several unique features that set it apart from existing solutions. One of the most notable was its integration of cloud computing, allowing for real-time collaboration and data management. This was a significant shift from traditional, locally-installed software, providing flexibility and accessibility to users anywhere in the world.

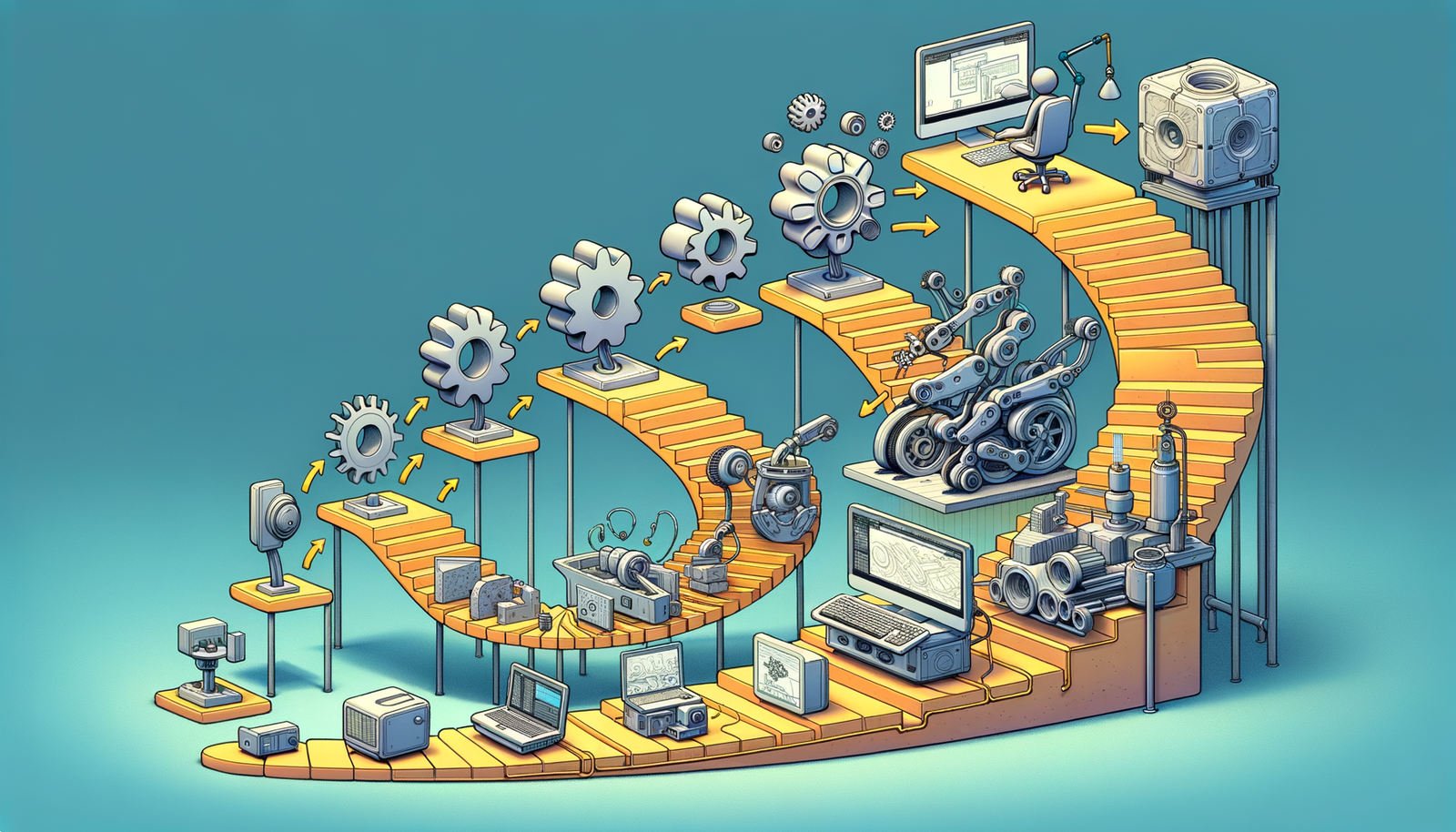

Other innovative features included parametric modeling, which allowed for precise control and modification of design parameters, and an integrated simulation environment for testing and validation. The seamless transition from design to manufacturing within the same platform was a game-changer, reducing the need for multiple software tools and simplifying the workflow.

Key Features and Evolution Over Time

Core Functionalities

Fusion 360's core functionalities encompass a wide range of tools designed to streamline the design-to-manufacturing process. These include:

- Parametric Modeling: Allows for the creation and modification of designs based on defined parameters, providing flexibility and precision.

- Simulation: Integrated tools for stress analysis, thermal analysis, and more, enabling designers to test and validate their designs within the same environment.

- Computer-Aided Manufacturing (CAM): Features for generating toolpaths and optimizing machining processes, bridging the gap between design and production.

These core functionalities enable users to iterate quickly, validate their designs, and move seamlessly into the manufacturing phase. The integration of these features within a single platform eliminates the need for data translation between different software tools, reducing errors and improving efficiency.

Updates and Upgrades

Since its launch, Fusion 360 has undergone numerous updates and upgrades, continually improving and expanding its capabilities. Some of the most significant updates include:

- Enhanced simulation tools, including the addition of nonlinear materials and event simulation.

- Improved CAM functionalities, such as advanced toolpath strategies and support for multi-axis machining.

- Increased integration with other Autodesk products, such as AutoCAD and Revit, and third-party tools.

User feedback has played a crucial role in shaping the evolution of Fusion 360. Autodesk actively engages with its user community through forums, surveys, and beta testing programs, using this input to guide future development. This collaborative approach ensures that the software continues to meet the needs of its users and stays at the forefront of technological advancements.

Impact and Future Prospects

Impact on Design and Manufacturing

Fusion 360 has had a profound impact on various industries, revolutionizing design processes and accelerating product innovation. By integrating design, simulation, and manufacturing within a single platform, it has enabled companies to reduce development cycles and bring products to market faster. The software's ability to facilitate collaboration and data sharing has also enhanced teamwork and communication, leading to more innovative and effective solutions.

An example of its impact can be seen in the automotive industry, where Fusion 360 has been used to streamline the design and production of complex components. Similarly, in the aerospace sector, the software has enabled engineers to create lightweight, optimized designs that meet stringent performance requirements.

Challenges and Criticisms

Despite its many advantages, Fusion 360 has faced its share of challenges and criticisms. One common issue has been the learning curve associated with transitioning from traditional CAD/CAM tools to a new, integrated platform. Autodesk has addressed this through extensive training resources, tutorials, and community support.

Another criticism has been related to performance and reliability, particularly in the early years. Autodesk has worked diligently to improve the software's stability and performance, with regular updates and enhancements. Additionally, the reliance on cloud computing has raised concerns about data security and accessibility, which Autodesk has addressed through robust security measures and offline capabilities.

Future Directions

The future of Fusion 360 looks promising, with several emerging trends poised to shape its evolution. Among these are the integration of artificial intelligence (AI) and machine learning, which could enhance design automation, predictive analytics, and optimization.

Autodesk's vision for Fusion 360 includes further improving its collaborative capabilities and expanding its integration with other tools and platforms. As technology continues to evolve, Fusion 360 is well-positioned to adapt and remain a leading solution in the CAD/CAM industry. The company’s commitment to innovation and user-centric development ensures that Fusion 360 will continue to meet the needs of designers, engineers, and manufacturers for years to come.

Also in Design News

Beyond CAD Files: Unified Design Graphs for Simulation-Driven, Manufacturable Digital Threads

March 06, 2026 11 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …