Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

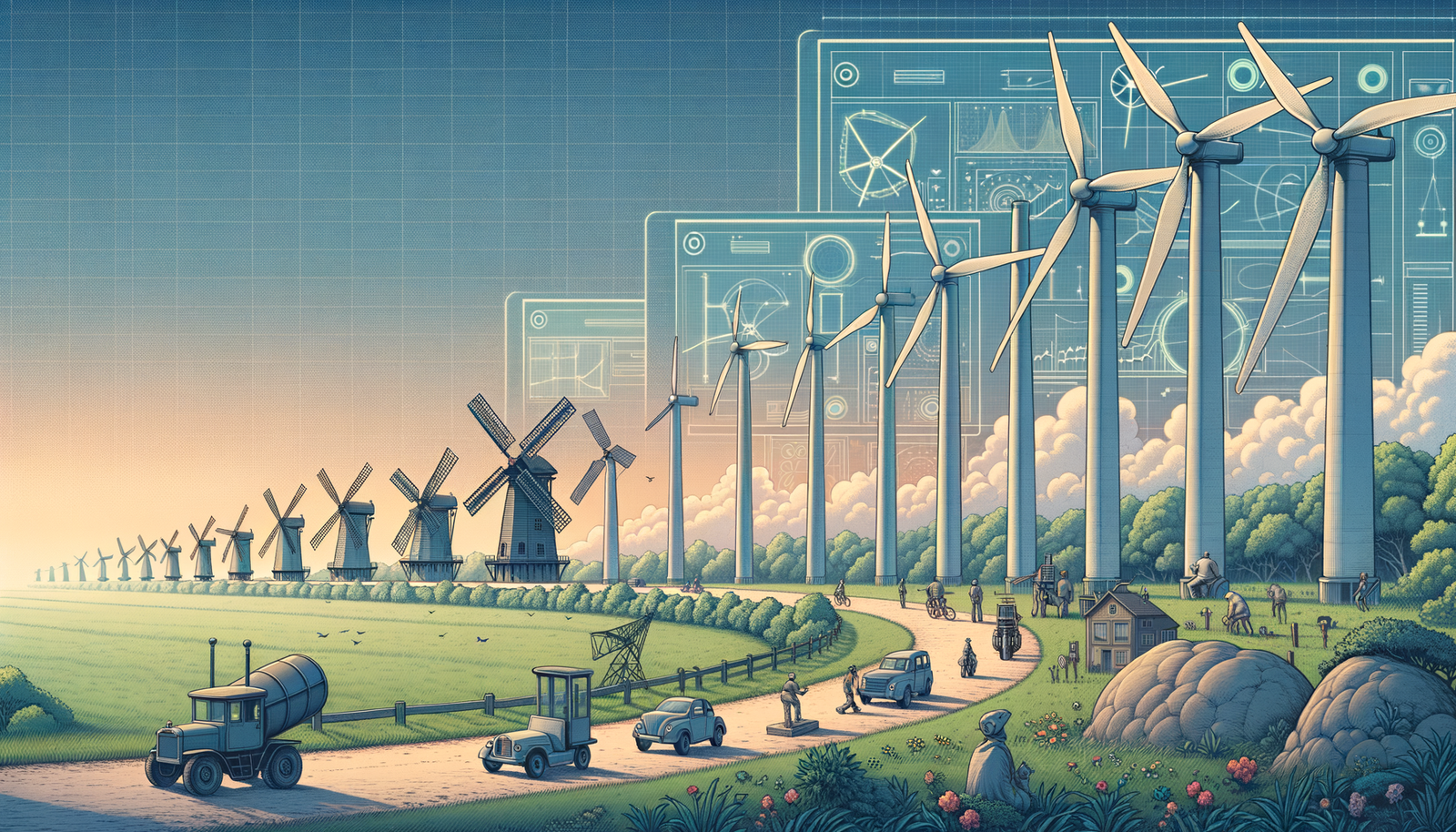

Design Software History: The Evolution of Design Software in Advancing Wind Turbine Technology and Its Impact on Renewable Energy Innovation

March 07, 2025 8 min read

Introduction to Design Software's Role in Wind Turbine Development

Wind turbines have become a cornerstone of the global shift toward renewable energy, representing a clean and sustainable alternative to fossil fuels. As nations strive to reduce carbon emissions and combat climate change, the deployment of wind energy has accelerated, making wind turbines a critical component of the modern energy landscape. The efficiency, reliability, and scalability of wind turbines are paramount, and achieving these goals requires meticulous design and engineering. This is where design software plays an indispensable role. From the initial concept to the final product, advanced design software aids engineers in optimizing every aspect of wind turbine development, enhancing performance while reducing costs and development time. The evolution of design software has been instrumental in addressing the complex challenges inherent in wind turbine technology, such as aerodynamic efficiency, structural integrity, and materials optimization. Historically, the tools available to engineers were limited, often relying on manual calculations and rudimentary models. However, as computational capabilities have expanded, so too has the sophistication of design software. Early computer-aided design (CAD) systems provided a foundation, but the advent of more specialized software has allowed for precise simulations and analysis that were previously unattainable. The integration of design software into wind turbine development has not only accelerated innovation but also enabled the industry to meet the growing demand for renewable energy solutions worldwide. Understanding the role of design software in this context is essential to appreciating how wind turbines have evolved and how they will continue to improve in the future. The historical context of design software's evolution reveals a trajectory from basic modeling tools to highly specialized applications that incorporate advanced mathematics, physics, and engineering principles, reflecting the increasing complexity and ambition of wind energy projects.Early Innovations and Software in Wind Turbine Design

The early days of wind turbine design were marked by a reliance on traditional engineering methods, with hand-drawn schematics and physical prototypes serving as the primary tools for development. The introduction of computer-aided design (CAD) in the late 20th century revolutionized this process, offering engineers a new way to conceptualize and refine wind turbine components. Companies like Autodesk, with their groundbreaking software AutoCAD introduced in 1982, provided one of the first widely accessible CAD tools, enabling more precise and efficient designs. Similarly, Parametric Technology Corporation (PTC) introduced Pro/ENGINEER in 1988, which became a foundational tool for parametric, feature-based modeling. These early software tools allowed engineers to create detailed 2D and 3D models of turbine components, such as blades, hubs, and nacelles, facilitating better visualization and analysis. Despite these advancements, integrating CAD into wind turbine design was not without challenges. One significant obstacle was the computational limitations of the hardware at the time. Early computers lacked the processing power to handle complex simulations, often resulting in simplified models that could not fully capture the intricacies of turbine dynamics. Additionally, there was a steep learning curve associated with CAD software, requiring engineers to develop new skills and adapt to a digital workflow. Furthermore, the lack of specialized modules for specific aspects of wind turbine design, such as aerodynamics and structural analysis, meant that engineers had to rely on generalized tools that were not always ideally suited for the task. Key companies in the wind energy sector began to recognize the potential of CAD in improving turbine design. For instance, Danish wind turbine manufacturer Vestas started integrating CAD into its design process in the 1980s, leveraging the technology to enhance the precision and efficiency of its turbines. Similarly, General Electric (GE), a major player in the energy industry, adopted CAD tools to streamline the development of its wind turbines. The early adoption of design software by these companies set the stage for more advanced applications in the future. The integration of CAD marked the beginning of a new era in wind turbine design, where digital tools would increasingly drive innovation and efficiency.Advancements in Design Software and Wind Turbine Efficiency

As wind turbine technology advanced, the need for more sophisticated design software became apparent. The limitations of early CAD tools prompted the development of specialized software capable of simulating complex physical phenomena critical to wind turbine performance. One significant advancement was the integration of finite element analysis (FEA) into turbine design. FEA allowed engineers to perform detailed structural analysis of turbine components, assessing stress, strain, and deformation under various load conditions. Software such as ANSYS and Abaqus, developed by ANSYS Inc. and Dassault Systèmes respectively, became essential tools in this regard. These programs enabled precise modeling of materials and structural behavior, ensuring that turbines could withstand harsh environmental conditions and prolonged operational stresses. In parallel, computational fluid dynamics (CFD) emerged as a crucial technology for optimizing the aerodynamic aspects of wind turbines. CFD software, like Fluent (by ANSYS Inc.) and STAR-CCM+ (by Siemens Digital Industries Software), allowed engineers to simulate airflow around turbine blades, analyze turbulence, and optimize blade shapes for maximum efficiency. The impact of CFD on blade optimization was profound, as even small improvements in blade design could result in significant increases in energy capture. By modeling the aerodynamic performance of blades under various wind conditions, engineers could iteratively refine designs to achieve optimal performance. Major software vendors played a pivotal role in refining turbine design through the development of integrated design platforms. Siemens Digital Industries Software, for instance, offered Simcenter, a comprehensive suite that combined FEA, CFD, and other simulation tools. Dassault Systèmes, with its 3DEXPERIENCE platform and CATIA software, provided advanced modeling capabilities and data management solutions. These platforms not only offered powerful simulation tools but also facilitated collaboration among multidisciplinary teams, streamlining the design process from concept to production. The role of parametric and generative design further advanced wind turbine technology by introducing new methods of exploring design possibilities. Parametric design, enabled by software like PTC Creo and Autodesk Inventor, allowed engineers to define design parameters and constraints, automatically generating variations to meet specific criteria. This approach facilitated rapid exploration of design alternatives and optimization of components. Generative design took this concept further by leveraging algorithms and artificial intelligence to generate complex, high-performance designs that would be impractical to conceive manually. These technologies enabled the creation of innovative turbine components that offered improved efficiency, reduced weight, and enhanced structural integrity. Collectively, these advancements in design software dramatically improved wind turbine efficiency and reliability. By harnessing FEA and CFD, engineers could address both structural and aerodynamic challenges with unprecedented precision. The contributions of major software vendors provided the tools necessary to handle the increasing complexity of turbine designs. The adoption of parametric and generative design methodologies opened new horizons for innovation, enabling the development of turbines that are more efficient, cost-effective, and capable of meeting the demands of a growing renewable energy market.Impact of Modern Design Software on Wind Energy

In the current era, modern design software has become a linchpin in the advancement of wind energy, driving significant improvements in turbine performance and operational efficiency. The advent of cloud computing has been particularly transformative, enabling real-time simulation and analysis that were previously beyond reach due to computational constraints. Software platforms now leverage the vast processing power of cloud infrastructure to run complex simulations faster and more efficiently. For example, Autodesk's Fusion 360 and Siemens' cloud solutions allow engineers to perform extensive simulations of turbine components and systems without the need for expensive, high-performance local hardware. This democratization of computational resources has accelerated the design process, reduced costs, and promoted collaboration across geographically dispersed teams. Another critical development is the integration of the Internet of Things (IoT) and data analytics into wind turbine design and operation. Advanced software platforms collect real-time data from sensors embedded in turbines, providing valuable insights into performance, environmental conditions, and component health. Companies like General Electric have pioneered this approach with their Predix platform, which utilizes IoT technologies to enable predictive maintenance and efficiency optimization. By analyzing data trends, engineers can:- Predict potential failures before they occur.

- Schedule maintenance proactively.

- Adjust operational parameters to maximize energy output.

- Terrain variations.

- Wind patterns and speeds.

- Environmental impact assessments.

- Proximity to power grids.

Conclusion

The journey of wind turbine development has been profoundly influenced by the evolution of design software, which has transformed the industry from its modest beginnings to its current status as a key player in the global energy landscape. The integration of computer-aided design, finite element analysis, computational fluid dynamics, and, more recently, cloud computing, IoT, and artificial intelligence, has enabled engineers to push the boundaries of what is possible. **Design software has not only enhanced the efficiency and reliability of wind turbines but has also accelerated innovation**, allowing for rapid prototyping and testing of new concepts. The collaboration between software developers and the wind energy industry has resulted in tools that are finely tuned to address the unique challenges of harnessing wind power, leading to significant advancements in turbine technology and performance. Despite these achievements, ongoing challenges remain that necessitate continued development and innovation. The variability of wind resources, environmental concerns, and the need for cost-effective solutions require constant refinement of both turbine designs and the software tools used to create them. There is also the pressing issue of integrating an ever-increasing number of wind turbines into existing power grids, which demands sophisticated modeling and simulation to ensure stability and reliability. Additionally, as turbines become larger and more complex, the need for highly accurate simulations of structural and aerodynamic behavior becomes even more critical. **Future developments in design software will likely focus on enhancing simulation accuracy, improving integration across different engineering disciplines, and leveraging AI to further optimize designs**. In the broader context, the partnership between design technology and sustainable energy solutions is vital for addressing the global challenges of climate change and resource depletion. Wind energy, empowered by advanced design software, offers a scalable and clean alternative to traditional power sources. The continued evolution of design tools will play a crucial role in making renewable energy more accessible and efficient. As we look ahead, it is clear that the synergy between engineering innovation and software development will be instrumental in achieving a sustainable energy future. The ongoing collaboration between companies like Siemens, Dassault Systèmes, Autodesk, and leaders in the wind energy sector will be essential in driving this progress. Ultimately, the transformative impact of design software on wind turbine development underscores the importance of technological advancement in addressing some of the most pressing issues facing our planet today.Also in Design News

Rhino 3D Tip: Rhino Material Optimization: Nesting, Lightweighting, and Cut-Length Reduction

December 31, 2025 2 min read

Read More

Design Software History: Constraint Solving in CAD: From Sketchpad to Modern Parametric Engines

December 31, 2025 12 min read

Read More

Intent-Aware Scan-to-BRep: Integrating LiDAR Point Clouds into Solid Modeling Pipelines

December 31, 2025 12 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …