Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

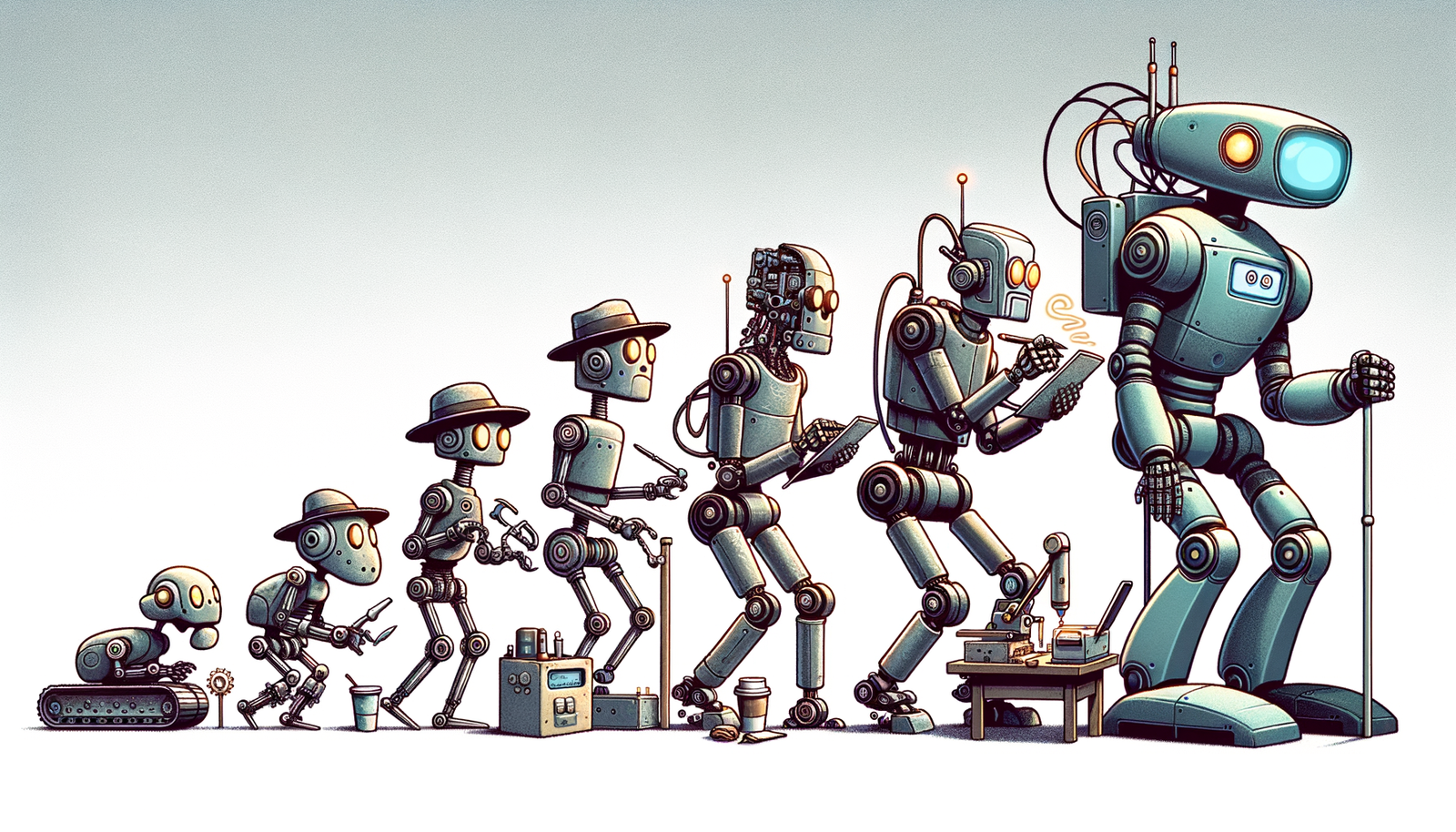

Design Software History: The Evolution of Collaborative Robots in Modern Design Processes

November 03, 2024 4 min read

Introduction to Collaborative Robots in Design

Collaborative robots, commonly known as cobots, represent a significant evolution in the field of automation. Unlike traditional industrial robots that operate in isolation from humans due to safety concerns, cobots are designed to work alongside human operators in shared workspaces. This fundamental distinction has opened new horizons in the design industry, where the seamless integration of human creativity and robotic precision is paramount. The journey towards cobots began with the advent of automation in manufacturing during the late 20th century, but it was not until the early 2000s that the concept of robots collaborating directly with humans gained traction. The integration of cobots into design environments has not only enhanced productivity but also improved safety standards, allowing for more efficient workflows and innovative outcomes.

Role of Cobots in the Design Process

In the modern design process, cobots have emerged as indispensable tools that assist designers and engineers in various capacities. One of the primary advantages of cobots is their ability to perform repetitive and precision-intensive tasks with high accuracy. This capability frees human designers to focus on the creative and conceptual aspects of design, fostering an environment where innovation thrives. The collaborative nature of cobots facilitates a fluid workflow, where humans and robots interact seamlessly. For instance, in automotive design, cobots can handle the meticulous assembly of prototypes while designers oversee and make adjustments in real-time. In architectural modeling, cobots assist in constructing complex scale models, ensuring precision that would be challenging to achieve manually.

Several industry leaders have effectively integrated cobots into their design processes. Universal Robots, a pioneer in the cobot industry, has formed partnerships with design firms to enhance production capabilities. Their collaborative robots are utilized in product prototyping, where precision and adaptability are crucial. Additionally, companies like KUKA Robotics have developed cobots that specialize in tasks such as welding and material handling, significantly impacting product design and development cycles.

- Architectural Modeling: Cobots aid in constructing detailed models, enabling architects to visualize and iterate designs efficiently.

- Automotive Design: Precision assembly and testing of components are enhanced by cobots, reducing errors and time-to-market.

- Product Prototyping: Rapid prototyping is facilitated by cobots' ability to work continuously with high accuracy.

Simulation and Testing with Cobots

The integration of cobots into simulation environments has revolutionized how design validation and testing are conducted. Advanced software tools like PTC's Creo and Siemens' NX have incorporated functionalities that allow designers to simulate cobot interactions within their design models. This integration enables the prediction of robot behavior during design tasks, ensuring that potential issues are identified and addressed before physical prototyping. The role of physics simulations is crucial in this context, as they provide insights into how cobots will perform in real-world scenarios, considering factors like force, motion, and material properties.

Innovations in virtual and augmented reality technologies have further enhanced these simulations. Designers can now engage with virtual representations of cobots within immersive environments, gaining a deeper understanding of collaborative processes. For example, using Microsoft's HoloLens, engineers can visualize cobot operations overlaid onto physical spaces, allowing for real-time adjustments and improvements. This level of simulation not only improves the efficiency of the design process but also reduces costs associated with physical testing and prototyping.

- Virtual Reality (VR): Enables complete immersion in a simulated environment for testing cobot interactions.

- Augmented Reality (AR): Allows overlaying of cobot simulations onto real-world environments for enhanced visualization.

Future Potential and Challenges

The future of cobot technology is promising, with emerging trends focusing on enhancing their functionality and ease of use. Advances in sensors, artificial intelligence (AI), and machine learning are at the forefront of this evolution. Improved sensors enable cobots to have more precise environmental awareness, which is essential for safety and efficiency. AI and machine learning algorithms allow cobots to learn from interactions and adapt to new tasks without extensive reprogramming. Companies like Fanuc and ABB Robotics are investing heavily in developing cobots with more intuitive interfaces, making them more accessible to designers without specialized programming knowledge.

Despite these advancements, several challenges need to be addressed. Safety concerns remain paramount, as the integration of cobots into shared workspaces requires rigorous adherence to regulatory standards. Ensuring that cobots can operate without posing risks to human colleagues is essential for widespread adoption. Additionally, there is a growing need for a skilled workforce capable of designing and operating these sophisticated systems. This demand highlights the importance of education and training programs focused on robotics and automation in design disciplines.

Conclusion

Collaborative robots have undeniably transformed the landscape of design and simulation processes. Their ability to work alongside humans has bridged the gap between robotic efficiency and human creativity, leading to innovative outcomes and streamlined workflows. As the technology continues to evolve, ongoing innovation and education will play crucial roles in unlocking the full potential of cobots. Looking ahead, it is foreseeable that the synergy between human designers and collaborative robots will become even more integral in shaping modern design environments, leading to advancements that were once considered beyond reach.

Also in Design News

Design Software History: Collaboration in Design Software: From File-Based PDM to Cloud-Native Co-Editing and Design Threads

December 23, 2025 9 min read

Read More

End-to-End Encryption for CAD/PLM: Protecting Design IP in Cloud Workflows

December 23, 2025 13 min read

Read More

Cinema 4D Tip: Camera-Based Projection Mapping Workflow for Cinema 4D

December 23, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …