Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: The Evolution of CAD in Hand Tool Design: From Manual Drafting to AI-Driven Innovation

October 01, 2024 5 min read

Introduction

The advent of Computer-Aided Design (CAD) has revolutionized numerous industries, and the hand tool industry is no exception. Traditionally, the design and development of hand tools were heavily reliant on manual drafting techniques, which, while effective, were time-consuming and limited in precision. The transition from these manual methods to computer-aided design marked a significant turning point in the industry, enabling designers to create more complex and ergonomic tools with unprecedented accuracy. This shift not only streamlined the design process but also opened up new possibilities for innovation in tool functionality and aesthetics.

In the early stages of this technological evolution, several key players emerged, driving the adoption of CAD in hand tool design. Companies like CADKEY and SolidWorks were instrumental in developing software that catered to the specific needs of tool designers. Their contributions laid the groundwork for modern CAD systems that are now integral to the industry. Milestones such as the introduction of 3D modeling capabilities and parametric design tools have profoundly impacted how hand tools are conceptualized and brought to market. As we explore the history of CAD in the hand tool industry, we will delve into these significant developments and examine how they have shaped the tools we use today.

Early Developments in CAD for Hand Tools

The initial foray into computer-aided design for hand tools was met with both excitement and challenge. Early CAD systems provided a new platform for designers to visualize their concepts digitally, but these systems were often limited in their capabilities. Companies like CADKEY, founded in the late 1980s, offered some of the first accessible CAD software for personal computers. CADKEY's software allowed designers to create 2D and 3D wireframe models, which was a significant advancement from traditional drafting. However, accurately modeling the intricate shapes and ergonomic features of hand tools proved to be a complex task with the technology of the time.

One of the primary challenges faced by early CAD systems was the inability to accurately represent organic shapes and curves essential in hand tool design. The limitations in computational power and software algorithms made it difficult to simulate the subtle contours that make tools comfortable and effective for human use. Moreover, the reliance on manual drafting conventions within these early CAD programs meant that designers were still constrained by the same limitations they sought to overcome. The transition from manual drafting to CAD required a paradigm shift in design thinking, which took time to develop fully.

Despite these challenges, the early adoption of CAD in hand tool design set the stage for future advancements. The ability to store and modify designs digitally reduced the time spent on revisions and allowed for easier collaboration among design teams. Companies began to recognize the potential of CAD to enhance productivity and started investing in software development tailored to their needs. The collaboration between software developers and tool manufacturers during this period was crucial for addressing the shortcomings of early CAD systems and paving the way for more sophisticated design tools.

Advancements in CAD Technology for Hand Tools

The evolution of CAD technology brought about significant advancements that transformed hand tool design. One of the most pivotal innovations was the introduction of parametric modeling. This approach allowed designers to create models with relationships and constraints that define how the geometry behaves. Software like SolidWorks, introduced in the mid-1990s, leveraged parametric modeling to enable more dynamic and flexible design processes. Designers could now adjust dimensions and features, and the software would automatically update the model accordingly. This capability was instrumental in optimizing tool ergonomics and functionality, as it facilitated iterative testing and refinement of designs.

Another significant development was the emergence of user-friendly interfaces in CAD software. Early CAD programs often required specialized knowledge and were not accessible to all designers. As companies like SolidWorks and Autodesk focused on improving usability, CAD became more democratized. Features such as drag-and-drop modeling, visual feedback, and intuitive navigation reduced the learning curve and allowed a broader range of designers to adopt CAD tools. This accessibility fostered greater innovation as more individuals could contribute to the design process without extensive training.

Collaborations between CAD software developers and tool manufacturers became increasingly common during this period. These partnerships were essential for tailoring CAD features to the specific needs of hand tool design. For example, manufacturers provided feedback on the requirements for modeling ergonomic grips or simulating the stress on tool components. CAD developers, in turn, integrated advanced simulation capabilities and material libraries into their software. This synergy between the software and manufacturing industries led to more robust and specialized CAD solutions that significantly enhanced the quality and performance of hand tools.

Current Trends and Future Directions

In today's landscape, CAD applications in hand tool design have reached new heights of sophistication. Modern CAD software incorporates advanced features such as simulation and prototyping, which allow designers to test the performance of their tools virtually before physical production. Simulation tools can model stress, strain, and other physical forces, enabling the optimization of tool durability and efficiency. Additionally, the integration of additive manufacturing, commonly known as 3D printing, has transformed prototyping. Designers can rapidly produce physical models directly from their CAD designs, facilitating quick iterations and refinements.

Current trends also point towards the increasing incorporation of Artificial Intelligence (AI) and machine learning in CAD software. AI algorithms can assist in generating design alternatives, optimizing shapes for specific functions, and even predicting potential design flaws. The ability to customize tools to individual user preferences is becoming more feasible as CAD systems can quickly adapt designs based on user input or biometric data. This level of customization enhances user experience and personalization in hand tools, catering to specific needs and preferences.

Looking forward, the future of CAD in the hand tool industry is poised to integrate more deeply with emerging technologies. We can anticipate advancements such as:

- The incorporation of virtual reality (VR) and augmented reality (AR) for immersive design experiences.

- Enhanced collaboration tools that allow real-time co-design across global teams.

- Greater use of cloud-based CAD systems for increased accessibility and scalability.

Conclusion

The journey from manual drafting to sophisticated CAD systems has been transformative for the hand tool industry. Computer-Aided Design has not only streamlined the design process but has also enabled designers to explore new frontiers in tool functionality and ergonomics. Key players like CADKEY and SolidWorks have been instrumental in driving these advancements, addressing early challenges, and introducing innovative features like parametric modeling. As technology continues to evolve, the integration of AI, additive manufacturing, and enhanced collaboration tools will further revolutionize hand tool design.

CAD's impact on the industry underscores the importance of embracing technological advancements to stay competitive and meet the evolving needs of users. The future holds exciting possibilities, with greater customization and efficiency on the horizon. As we continue to innovate and improve upon the tools that are fundamental to countless tasks and professions, CAD remains at the forefront of this ongoing evolution, shaping the way we design and interact with our tools.

Also in Design News

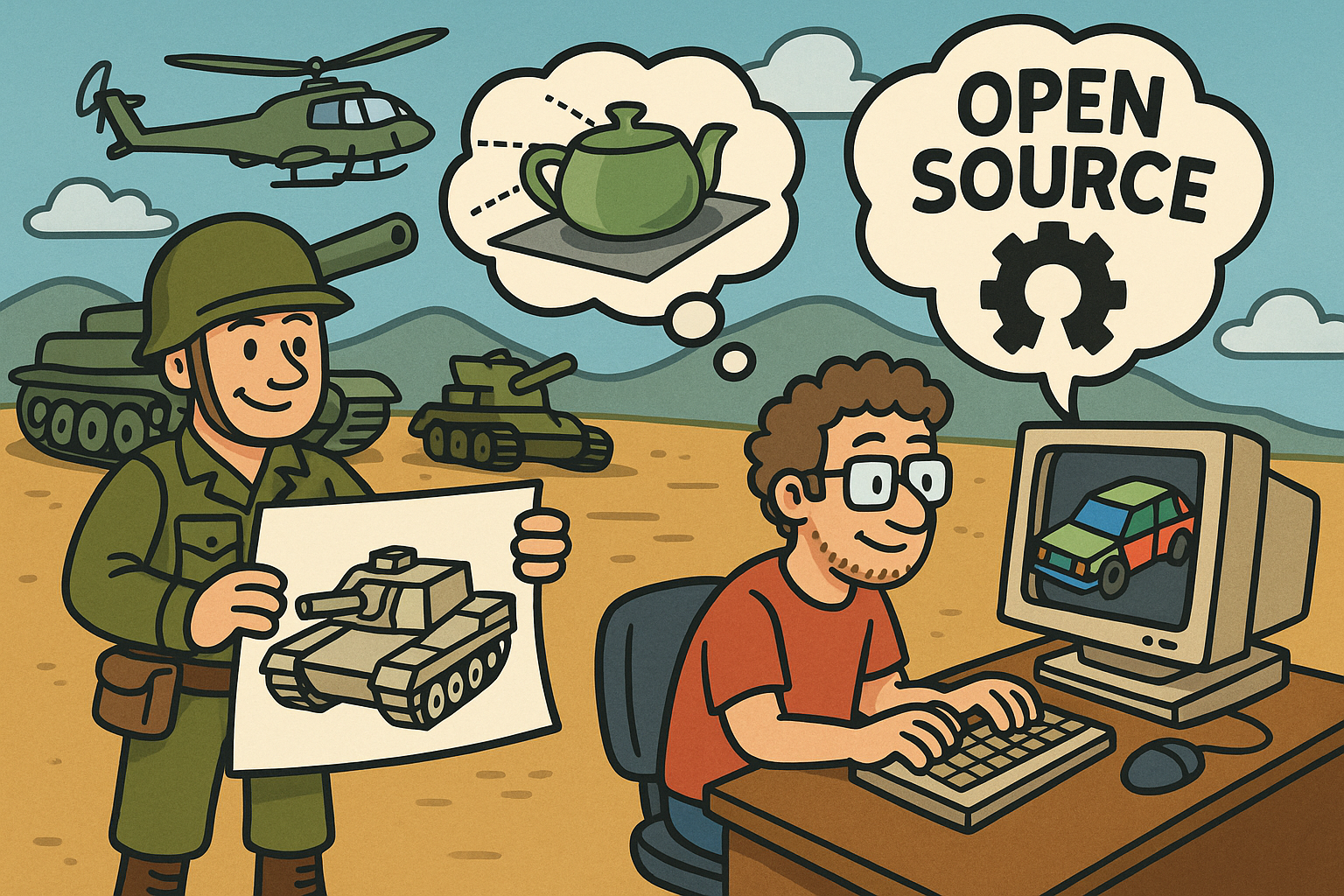

Design Software History: BRL-CAD: Military Roots to Open-Source CSG and Deterministic Ray-Tracing for Simulation

March 07, 2026 13 min read

Read More

Continuous Integration for Design: Operationalizing DesignOps for CAD, CAE, and Documentation

March 07, 2026 16 min read

Read More

Cinema 4D Tip: Cinema 4D Light Baking Workflow and Best Practices

March 07, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …