Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: The Evolution and Impact of Siemens NX in Bridging Design and Manufacturing

November 25, 2024 3 min read

Introduction

Siemens NX stands as a pivotal tool in the realms of design and manufacturing, renowned for its comprehensive capabilities that seamlessly connect the two disciplines. This powerful software suite has evolved over the years to become a cornerstone in industries that demand precision and innovation. By integrating robust design features with sophisticated manufacturing solutions, Siemens NX bridges the traditional gap between conceptualization and production. Understanding this integration is crucial for professionals aiming to enhance efficiency and foster collaboration within their workflows. The evolution of Siemens NX reflects a journey of technological advancement, highlighting the importance of software that not only adapts to but also anticipates the needs of modern engineering and manufacturing practices.

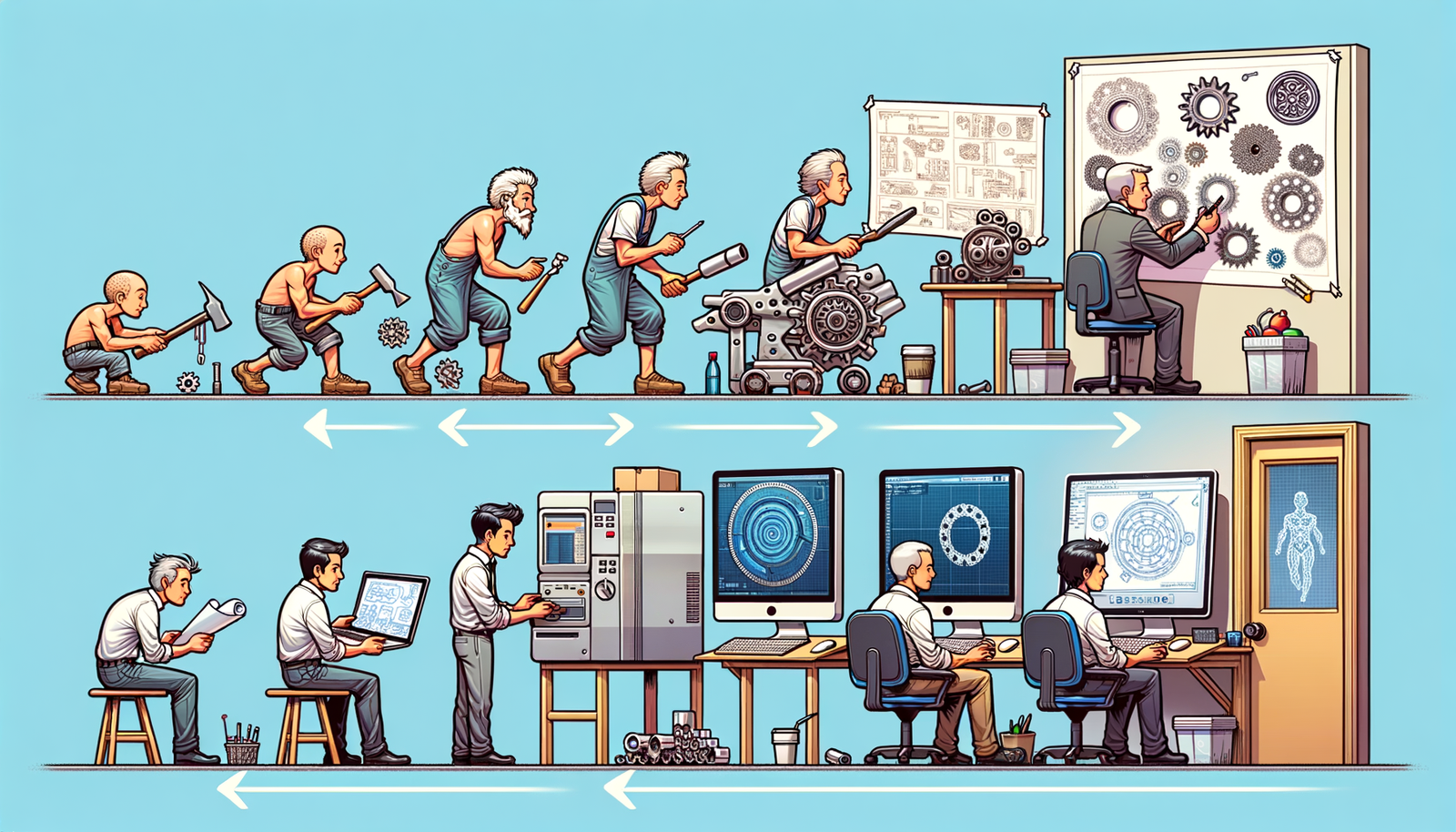

Historical Context and Development

The origins of Siemens NX can be traced back to the early days of computer-aided design (CAD) and computer-aided manufacturing (CAM), with roots in the seminal software known as Unigraphics. Unigraphics Solutions Inc., which later became part of Siemens PLM Software, was instrumental in pioneering early CAD/CAM technologies. Over the years, the software underwent significant transformations, culminating in the robust platform known today as Siemens NX. Key milestones in its development include the introduction of advanced modeling techniques, the integration of parametric design capabilities, and the incorporation of high-level simulation tools. These advancements addressed historical challenges in integrating design with manufacturing solutions, such as the need for a unified platform to reduce data translation errors and improve collaboration between different departments. The continuous evolution of Siemens NX reflects a commitment to overcoming these challenges by providing a holistic environment that enhances productivity and innovation in engineering processes.

Core Technologies and Functionalities

At the heart of Siemens NX lies a suite of primary design tools that empower engineers to create intricate models with precision and efficiency. The software offers comprehensive features for solid and surface modeling, enabling the development of complex geometries for a wide range of applications. A significant aspect of Siemens NX is its manufacturing modules, which are intricately linked with the design components. These modules facilitate tasks such as toolpath generation, machining simulation, and manufacturing process planning, ensuring a smooth transition from design to production. Advanced functionalities like synchronous technology revolutionize the way designers interact with models by allowing real-time edits without the constraints of history-based modeling. Furthermore, the inclusion of generative design features leverages algorithmic processes to optimize designs based on specified criteria, leading to innovative solutions that may not emerge through traditional design methods. This synergy of design and manufacturing technologies within Siemens NX not only streamlines workflows but also opens new avenues for creativity and efficiency.

Real-world Applications and Impact

Siemens NX has a profound impact across various industries, serving as a critical tool in sectors such as aerospace, automotive, and consumer products. In aerospace, for instance, the software's ability to handle complex assemblies and precise tolerances is essential for designing components that meet stringent safety and performance standards. The automotive industry benefits from Siemens NX through its advanced simulation capabilities, which allow for the analysis and optimization of parts to enhance vehicle efficiency and safety. The consumer products sector leverages the software's robust design features to create aesthetically pleasing and functional products that meet market demands. Industry professionals frequently highlight the role of Siemens NX in facilitating collaboration among teams, as its integrated platform enables seamless communication between designers, engineers, and manufacturers. This integration significantly improves design-to-manufacturing workflows, reducing time-to-market and fostering innovation. By providing tools that support every stage of product development, Siemens NX empowers organizations to achieve their goals more effectively and efficiently.

Conclusion

Reflecting on the evolution of Siemens NX reveals its substantial influence in shaping modern design and manufacturing practices. The software's integration of comprehensive design tools with advanced manufacturing capabilities represents a significant advancement in engineering technology. Looking to the future, trends in integrated design software suggest a continued emphasis on connectivity, collaboration, and the utilization of emerging technologies such as artificial intelligence and additive manufacturing. Potential developments within Siemens NX may include enhanced cloud-based functionalities, increased automation in design processes, and further integration of simulation and real-time data analytics. The ongoing need for comprehensive software solutions like Siemens NX is evident, as they play a crucial role in enhancing productivity and fostering innovation in design and engineering. As industries evolve and face new challenges, tools that bridge the gap between design and manufacturing will remain indispensable in driving progress and achieving excellence.

Also in Design News

Rhino 3D Tip: Grasshopper Cluster Best Practices for Reuse, Performance, and Team Workflows

November 22, 2025 2 min read

Read More

Cinema 4D Tip: Cinema 4D Sculpting Workflow: Layered Low-to-High Detail and Baking

November 22, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …