Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: CAMWorks: A Historical Perspective on CAD/CAM Integration and Technological Advancements

July 12, 2024 4 min read

Introduction to CAMWorks

CAMWorks is a pivotal tool in the realm of Computer-Aided Manufacturing (CAM). This software integrates seamlessly with Computer-Aided Design (CAD) systems, enabling manufacturers to automate the machining process while ensuring precision and reducing production time. CAMWorks primarily functions to generate toolpaths and CNC (Computer Numerical Control) code directly from the CAD models, capitalizing on the data-rich environment of the digital design.

The concept of CAM is integral to modern manufacturing, bridging the gap between digital design and physical production. As manufacturing processes become more complex, the demand for accurate and efficient CAM software increases. CAMWorks stands out by facilitating a streamlined workflow that minimizes errors and optimizes manufacturing operations.

Historically, the integration of CAD and CAM systems has been a significant advancement in manufacturing technology. This amalgamation allows for a seamless transition from design to production, effectively reducing lead times and enhancing precision. The role of CAMWorks in this context cannot be overstated, as it exemplifies the importance of integrated solutions in advancing industrial capabilities.

Early Development and Innovations

Founders and Founding

CAMWorks was developed by HCL Technologies, a global technology company renowned for its innovation in software solutions. The vision behind CAMWorks was to create a CAM solution that could integrate intuitively with CAD systems, specifically SolidWorks. This integration aimed to streamline the design-to-manufacturing process, making it more efficient and reducing the margin for error.

The early development of CAMWorks was spearheaded by a team of visionary engineers and software developers at HCL Technologies. They recognized the need for feature-based machining, a revolutionary concept at the time, which allowed the software to automatically recognize features (such as holes, pockets, and slots) within the CAD model and generate the necessary toolpaths.

Core Innovations

CAMWorks brought several technological innovations to the CAM software landscape. One of the most significant was its seamless integration with SolidWorks, one of the leading CAD software platforms. This integration allowed users to work within a single environment without switching between different software tools, significantly enhancing productivity and reducing the learning curve.

Another groundbreaking innovation was the introduction of feature-based machining. This approach enabled CAMWorks to automatically identify and generate machining operations based on the features present in the CAD model. This automation drastically reduced the time required to create machining strategies and ensured greater consistency and accuracy in the manufacturing process.

Evolution and Technological Advances

Major Milestones

The evolution of CAMWorks is marked by several key milestones and significant updates that have continuously enhanced its capabilities. Some of the major milestones include:

- The initial release of CAMWorks integrated with SolidWorks, which set a new standard for CAD/CAM integration.

- The introduction of advanced feature recognition and automatic machining strategies.

- Regular updates that incorporated user feedback and technological advancements, ensuring that CAMWorks remained at the forefront of the industry.

CAMWorks has also benefited from strategic partnerships and collaborations that have expanded its functionality and integration capabilities. These collaborations have enabled CAMWorks to offer a more comprehensive solution to its users, catering to a wide range of manufacturing needs.

Technological Enhancements

Over the years, CAMWorks has seen numerous technological enhancements that have kept it relevant in the rapidly evolving manufacturing landscape. Some of these enhancements include:

- The introduction of intelligent machining automation, which leverages advanced algorithms to optimize machining processes.

- Integration with cloud computing and IoT (Internet of Things), enabling enhanced connectivity and data analytics.

- Continuous improvements to the user interface and user experience, making the software more accessible and efficient for users.

These advancements have transformed CAMWorks into a powerful tool that not only automates the machining process but also provides valuable insights and analytics to improve overall manufacturing efficiency.

Impact and Future Prospects

Industry Impact

The impact of CAMWorks on the manufacturing industry has been profound. Engineers and designers across various sectors have lauded the software for its ability to significantly enhance productivity and innovation. Some of the key benefits reported by users include:

- Reduced lead times due to the seamless integration of CAD and CAM.

- Increased accuracy and consistency in machining operations.

- Enhanced ability to handle complex geometries and intricate designs.

Future Directions

Looking ahead, the future of CAMWorks is poised for exciting developments. Potential future advancements include:

The potential of AI-driven machining is particularly promising. By incorporating artificial intelligence and machine learning algorithms, CAMWorks could further optimize machining strategies, predict maintenance needs, and adapt to changing manufacturing conditions in real-time. This would mark a significant leap forward in the capabilities of CAM software.

Additionally, there are speculations about further integration with advanced manufacturing technologies, such as additive manufacturing and robotics. This would enable CAMWorks to provide a comprehensive solution that covers the entire spectrum of modern manufacturing processes.

Conclusion

In conclusion, CAMWorks has played a critical role in the history of design software, particularly in the realm of CAM. Its integration with CAD systems, innovative features, and continuous technological advancements have made it an indispensable tool in modern manufacturing. As the industry evolves, CAMWorks is well-positioned to continue leading the way, driving productivity and innovation in manufacturing processes.

The ongoing evolution of CAD/CAM technologies promises to transform the manufacturing landscape further, and CAMWorks will undoubtedly be at the forefront of these changes, shaping the future of how products are designed and manufactured.

Also in Design News

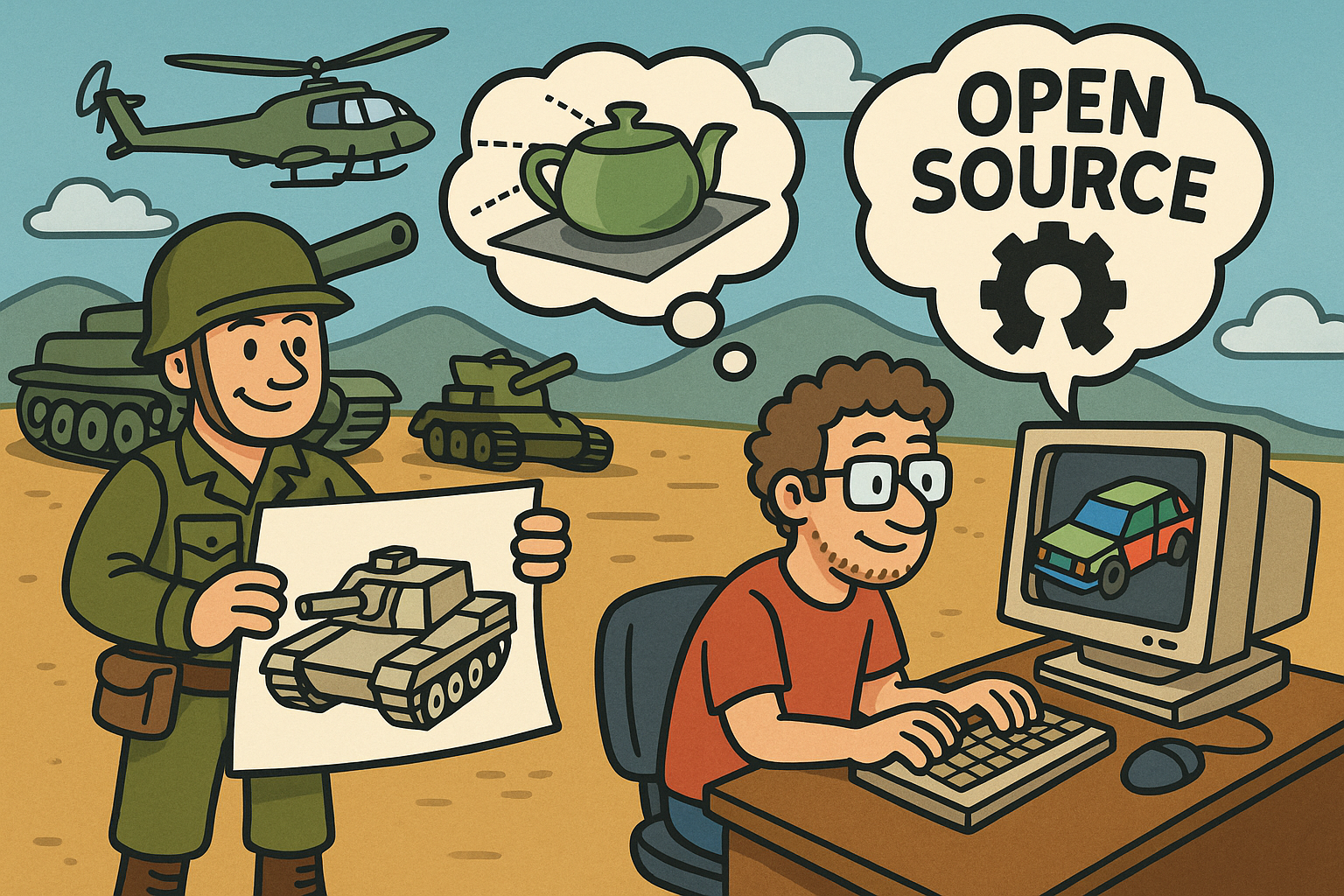

Design Software History: BRL-CAD: Military Roots to Open-Source CSG and Deterministic Ray-Tracing for Simulation

March 07, 2026 13 min read

Read More

Continuous Integration for Design: Operationalizing DesignOps for CAD, CAE, and Documentation

March 07, 2026 16 min read

Read More

Cinema 4D Tip: Cinema 4D Light Baking Workflow and Best Practices

March 07, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …