Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Autodesk Mechanical Desktop: Bridging 2D and 3D Design in CAD History

July 26, 2024 4 min read

Introduction to Autodesk Mechanical Desktop

Autodesk Mechanical Desktop, an innovative software developed by Autodesk, was first introduced in the mid-1990s. The initial version, Mechanical Desktop 1.0, was released in 1996. This software aimed to bridge the gap between two-dimensional (2D) and three-dimensional (3D) design, offering mechanical engineers a more advanced tool for creating and documenting their designs.

In the early 1990s, the design software landscape was dominated by 2D CAD applications, with Autodesk's AutoCAD being one of the leading products. However, the market was evolving rapidly, and there was a growing need for 3D modeling capabilities to enhance the design process. Companies were looking for software that could streamline design iterations, improve accuracy, and provide better visualization of complex mechanical parts. Autodesk Mechanical Desktop emerged to address these needs.

The introduction of Mechanical Desktop was a significant milestone in the history of CAD, marking a transition from purely 2D drafting to more sophisticated 3D modeling. This shift was essential for industries that required precise and complex mechanical designs, such as automotive, aerospace, and manufacturing. Mechanical Desktop played a crucial role in this transition, making it easier for engineers to adopt 3D design methodologies.

Key Technologies and Features

Mechanical Desktop introduced several core technologies that set it apart from other CAD tools of its time. One of the most important advancements was the introduction of **parametric and feature-based modeling**. This technology allowed users to define and manipulate design parameters, enabling easy modifications and updates to the model without having to redraw the entire design.

Another key feature was its integration with AutoCAD. Mechanical Desktop was built on top of the AutoCAD platform, which meant that users could leverage their existing knowledge of AutoCAD while taking advantage of the new 3D modeling capabilities. This **integration** also ensured compatibility with the vast library of AutoCAD files, making the transition to Mechanical Desktop smoother for existing AutoCAD users.

Mechanical Desktop offered a range of notable features and tools that enhanced the design process. These included:

- Sketching and Part Modeling: Users could create complex sketches and convert them into 3D models using various modeling techniques.

- Assembly Modeling and Constraints: The software allowed users to assemble multiple parts, define constraints, and simulate the movement of mechanical components.

- Drawing and Documentation Capabilities: Mechanical Desktop provided robust tools for creating detailed engineering drawings and documentation, crucial for manufacturing and fabrication.

Interoperability and file compatibility were also significant strengths of Mechanical Desktop. The software supported various CAD formats, allowing users to import and export files easily. This capability facilitated collaboration with other CAD systems and ensured that Mechanical Desktop could fit seamlessly into existing workflows. Additionally, its compatibility with other Autodesk products, such as AutoCAD and Autodesk Inventor, provided users with a comprehensive suite of tools for their design needs.

Influence on Design Processes

The introduction of Autodesk Mechanical Desktop had a profound impact on mechanical engineering workflows. By streamlining design iterations and modifications, the software enabled engineers to work more efficiently and respond quickly to design changes. The **parametric modeling** capabilities allowed for easy adjustments to design parameters, reducing the time and effort required to update models. This flexibility was crucial for industries where design iterations are frequent and rapid prototyping is essential.

Mechanical Desktop also enhanced the accuracy and precision of designs. The ability to create detailed 3D models and assemblies allowed engineers to visualize and analyze their designs more effectively. This improved accuracy reduced the likelihood of errors in the final product, leading to higher quality and more reliable mechanical systems.

When compared to other contemporary CAD tools, Mechanical Desktop had several strengths and weaknesses. Competitors like Pro/ENGINEER and SolidWorks offered robust 3D modeling capabilities, but Mechanical Desktop's integration with AutoCAD and its parametric modeling technology provided unique advantages. However, some users found the user interface of Mechanical Desktop to be less intuitive compared to these competitors.

Legacy and Evolution

As technology advanced, Autodesk began to shift its focus from Mechanical Desktop to newer technologies. In the early 2000s, Autodesk introduced Autodesk Inventor, a more advanced 3D CAD software that offered enhanced modeling capabilities and improved user experience. The transition from Mechanical Desktop to Inventor was driven by the need to provide users with more powerful tools that could handle increasingly complex designs.

The shift to Inventor had a significant impact on the user base and industry standards. While some users were initially hesitant to make the transition, many quickly recognized the benefits of the new software. Autodesk provided support and training to help users migrate from Mechanical Desktop to Inventor, ensuring a smooth transition.

Despite the transition, the concepts introduced by Mechanical Desktop have persisted in modern CAD tools. Parametric and feature-based modeling, integration with other software, and robust drawing and documentation capabilities are now standard features in many CAD applications. Mechanical Desktop's legacy can be seen in the continued evolution of CAD software, which builds on the foundation laid by this pioneering tool.

In conclusion, Autodesk Mechanical Desktop played a pivotal role in the history of CAD, marking a significant transition from 2D to 3D design. Its introduction of parametric modeling and integration with AutoCAD set new standards for mechanical design software. While the industry has moved on to more advanced tools like Autodesk Inventor, the influence of Mechanical Desktop continues to be felt. Its contributions to the evolution of design software and processes have left a lasting legacy that continues to shape the future of CAD.

Also in Design News

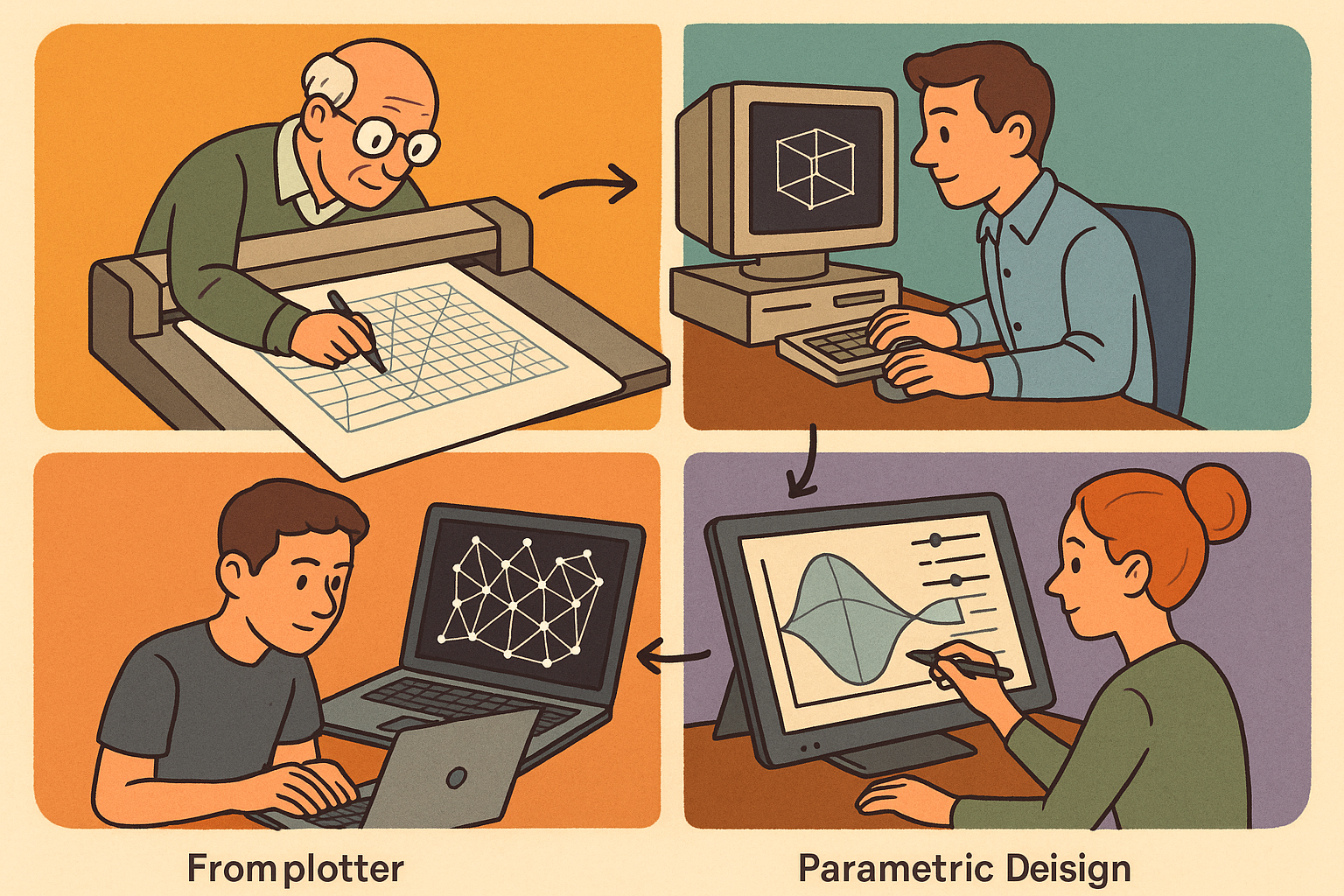

Design Software History: From Plotters to Procedural Intent: A Technical History of Generative and Parametric Design Software

January 04, 2026 13 min read

Read More

Semantic Meshes: Enabling Analytics-Ready Geometry for Digital Twins

January 04, 2026 12 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …