Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Autodesk's Unified Ecosystem: Transforming Additive Manufacturing from Concept to Production

June 02, 2025 5 min read

Introduction

Additive manufacturing has surged from niche prototyping to mission-critical production in under a decade, pushing designers to rethink how digital models are conceived, verified, and delivered to the factory floor. Traditional CAD alone cannot keep pace with the complexity of organic geometries, process-induced distortions, and multi-material possibilities now demanded by aerospace, biomedical, and consumer sectors. Autodesk has responded by knitting together a cohesive ecosystem—anchored by Fusion 360, Netfabb, PowerMill, and Autodesk Platform Services—that couples artificial intelligence, cloud computing, and high-fidelity physics into a unified workflow. The result is an environment in which design intent, manufacturability, and business metrics coexist from the first sketch to the final build file.

Generative Design for Lightweighting and Performance

The centerpiece of Autodesk’s additive workflow is the **cloud-based generative engine** embedded in Fusion 360. Designers specify functional loads, attachment points, keep-out zones, and preferred manufacturing processes; the solver then explores thousands of geometric permutations while respecting additive constraints such as minimum wall thickness, overhang angles, and recoater clearance. Unlike conventional topology optimization that merely carves away material, generative design uses evolutionary algorithms to cross-pollinate “survivor” geometries, yielding biomimetic structures frequently unattainable through manual modeling.

In production scenarios the weight savings routinely reach **40 – 60 %** without compromising stiffness or fatigue life. The algorithm’s multi-objective scoring allows practitioners to trade off part mass, modal frequencies, and even CO2 emissions per build. Because each design iteration returns metadata—build orientation, machine time, support volume—decision-makers can weigh cost and sustainability alongside mechanical performance.

- Automatic geometry filtering ranks candidates by estimated print cost, post-processing effort, and in-situ inspection accessibility.

- Manufacturing-aware mode eliminates solutions that exceed powder bed envelope size or violate scan speed limits for laser powder bed fusion (LPBF).

- Exported designs arrive as high-quality B-reps, preserving parametric features for downstream edits and finite element verification.

Thanks to direct hand-off to Netfabb, support strategies and slicing parameters can be simulated moments after the generative study converges. This immediacy short-circuits traditional “throw it over the wall” delays between design and manufacturing divisions, dramatically shrinking the iteration loop and enabling truly concurrent engineering.

Integrated Lattice & Infill Tools for Functional Grading

Weight reduction is only half the additive story; targeted performance enhancements often arise from lattice architectures that tune local material properties. Netfabb’s lattice assistant exposes rule-based controls for cell topology—tetrahedral, Kelvin, gyroid, or custom infills—while letting engineers sweep gradients across a part using implicit equations or voxel maps. The interface visualizes how cell edge thickness, beam diameter, and relative density morph along stress trajectories, giving unprecedented agency over **functionally graded structures**.

Inside Fusion 360, the Volumetric Latticing environment empowers designers to embed channels for forced convection or to create shock-absorbing foam regions. During each tweak, a color-coded preview updates live, relaying projected Young’s modulus, Poisson’s ratio, and thermal conductivity. These “digital twins” of micro-architecture feed directly into fusion-based FEA without meshing overhead, courtesy of GPU-accelerated implicit kernels. The same workflow enables:

- Biomedical implants with surface porosity optimized for **osseointegration** while preserving dense cores for load transfer.

- Battery housings featuring integral heat spreaders that wick joule heat away from cells during high-rate discharge.

When designs mature, they travel to the printer driver as native 3MF or proprietary vendor packages—no third-party plug-ins, no STL tessellation loss—and remain editable should qualification data mandate micro-geometry tweaks.

Process Simulation & Defect Prediction

An ambitious geometry is worthless if it fails midway through fabrication. Netfabb Simulation addresses this by modeling powder-bed fusion, binder jetting, and Directed Energy Deposition (DED) in a non-linear thermo-mechanical solver. The software predicts **residual stress, distortion, and support detachment** long before a build begins, relying on calibrated material models that incorporate phase changes, scan strategies, and layer-wise heat accumulation.

Engineers employ an “adapt-and-resimulate” loop: change orientation, repose supports, recut hatched islands, and then rerun the solver until critical displacement thresholds fall within tolerance. For DED, results can be funneled straight into PowerMill Additive, which recalculates multi-axis toolpaths that pre-compensate for predicted bead growth and thermal shrinkage. This closed feedback cycle:

- Reduces scrap stemming from recoater crashes or hot-spot delamination.

- Minimizes post-machining stock, saving subsequent CNC runtime.

- Builds trust in metal AM for safety-critical components.

Automatic support generation further shortens programmer effort. Algorithms vary support density along overhang angles, minimize shadowed areas that trap powder, and generate perforated breakaway zones to speed removal. Because support trees are co-simulated with their parent geometry, the final package fully accounts for added stiffness and thermal conduction pathways.

End-to-End Cloud Collaboration and Data Management

Fusion 360’s unified CAD/CAM/CAE spine eradicates the file-flinging that plagues siloed organizations. A single versioned dataset sits in the Autodesk cloud, accessible through desktop, browser, or mobile. Designers can sketch, analysts can mesh, and machinists can post G-code on the same model, with automatic propagation of edits via associative references.

**Concurrency** is safeguarded through branch-merge controls reminiscent of software development pipelines. Every parameter tweak leaves a timestamped breadcrumb, simplifying regulatory traceability and ISO 9001 audits. Reviewers annotate 3D markup directly inside the viewer; no PDF round-trips or ambiguous screenshot emails. For enterprises with bespoke tooling, Autodesk Platform Services opens RESTful endpoints so PLM systems, ERP dashboards, or IoT sensors can pull bill-of-materials data or push in-process signals back into the design loop.

Typical customizations include:

- Automatic creation of digital traveler documents populated with material lot codes and machine health metrics.

- Serverless scripts that trigger lattice re-optimization when sensor data shows underutilized thermal capacity in live builds.

Such integrations ensure that additive projects remain transparent from initial proposal to shop-floor validation, shrinking procurement risk and increasing stakeholder confidence.

Open Material Libraries and Qualification Ecosystem

Material selection no longer hinges on vendor datasheets alone. Fusion 360 ships with a searchable repository that spans stainless steels, nickel superalloys, ESD-safe photopolymers, and chopped-fiber composites, each tagged with tensile, creep, and thermal expansion curves. Collaborative agreements with hardware providers inject **validated scan parameters**—laser power, hatch spacing, bed temperature—directly into the workspace, sparing users from days of trial coupon builds.

Where exotic alloys or bio-resorbable materials are mandated, engineers can import custom tensile bars or nano-indentation datasets. The software’s Bayesian updater fits constitutive models to the empirical curves, yielding digital material cards immediately usable in Netfabb Simulation or Nastran In-CAD. To align with regulatory bodies, guideline templates reflect ASTM F42 terminology and ISO/ASTM 52900 nomenclature, prompting users to attach porosity CT scans, micrograph imagery, and build log hashes as they progress through qualification gates.

Key advantages of Autodesk’s material framework include:

- Side-by-side comparison views that rank alloys by energy density window, overhanging bridge length, and cost per cm3.

- Automatic flagging of incompatible process-material pairs—for instance, copper alloys on low-power LPBF rigs—helping newcomers avoid expensive missteps.

- Exportable material cards in JSON and XML for enterprise PLM ingestion.

By lowering the barrier to trustworthy data, Autodesk amplifies the adoption of emerging feedstocks, giving both startups and Fortune 500 companies a standardized on-ramp to industrial additive production.

Conclusion

From AI-driven concept generation to micro-architecture tailoring, from predictive simulation to real-time collaboration, Autodesk delivers a **cohesive toolchain** that collapses the gulf between design creativity and manufacturing reality. Engineers gain the agility to explore radical forms, validate them against stringent performance criteria, and shepherd them through qualification—all within a single, cloud-enabled environment. The payoff is shorter development cycles, lower unit costs, and the democratization of capabilities once reserved for well-funded laboratories. Whether you are a two-person hardware startup or a multinational firm modernizing legacy supply chains, the Autodesk ecosystem offers trial access and modular licensing paths that scale with your ambition. Engage with the platform today to accelerate your own additive manufacturing journey and unlock the next wave of product innovation.

Also in Design News

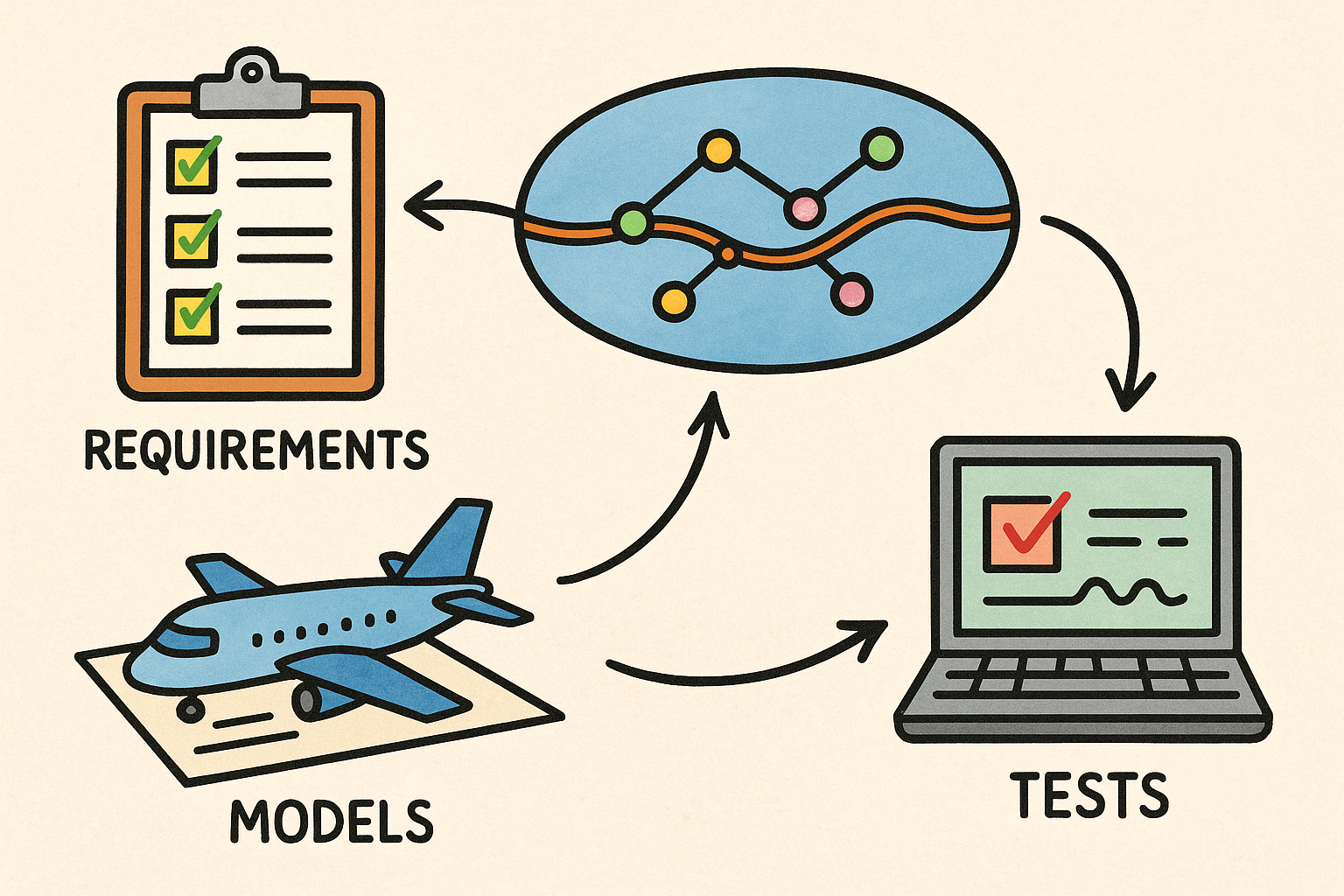

Semantics-First Digital Thread: Linking Requirements, Models, and Tests for Traceable Engineering

February 17, 2026 12 min read

Read More

Cinema 4D Tip: UV Tiling Best Practices for Cinema 4D and Redshift

February 17, 2026 2 min read

Read More

V-Ray Tip: Reflection Catcher Workflow for Photoreal Plate Integration

February 17, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …