Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

The Edge: In Norbert Geelen’s Seat

June 07, 2013 7 min read

Novedge: Tell us a bit about who you are and what you do

Norbert Geelen: I am an Industrial Designer.

After having completed my studies at the University of Essen, I started freelancing at Studio Matteo Thun in Milan/Italy.

Together with Robert Kilders, I founded the design studio bert&bert in 1997.

Since 2005 I have been working on my own as Norbert Geelen Industrial Design based both in my German office in Straelen and in my Milan studio.

Though I have designed a wide variety of distinct products, I have specialized in contract and office furniture design, mainly high-quality seating and tables.

Novedge: What has been your biggest inspiration and what keeps you inspired?

Norbert Geelen:Atari founder Nolan Bushnell once said “The ultimate inspiration is the deadline” and I can totally relate to that. I believe that only the pressure of time running out, the sense of aggregation and concentration when you are forced to get to the core of the matter can really trigger the creative momentum. After all, creativity was born as a human's answer to jeopardy, threat, danger.

While we don't need it to fight existential threats anymore (or maybe we do, but that's another story) it still needs stress and exitement to emerge.

Of course that doesn't mean there is no need for all kinds of creative input: like everybody else I am constantly looking for every information I can get hold of about interesting projects in all creative disciplines: other product designers' work, fashion, movies, technology, science, art, crafts, literature etc. and just about anything that stimulates my curiosity.

Novedge: What is a recent project that you worked on?

Norbert Geelen:During the last two years I worked on two major projects for Kusch+Co, a German producer of contract and office furniture.

These two products are Volpino, a range of plastic shell armchairs and São Paulo, a series of task- and conference- swivel chairs and its respective partner chairs.

Volpino is a series of small armchairs based on a polypropylene seat shell. The design is conceived as the “little brother” of Volpe, a fully upholstered armchair I designed for Kush+Co a couple of years ago. The attachment scheme of the different bases however is taken from the series uni_verso, a multi purpose chair and another project of mine for Kusch+Co. Beyond the obvious logistical advantages of this “shared platform” strategy, these series and a matching table range grow together to one large “patchwork family” where mixing and matching different products from different lines becomes natural and logical.

On the other hand, adapting the sinuous seat shell to an existing seat base without compromising its organic, sensual and friendly character was the main sculptural challenge of this project.

As my other projects for Kusch+Co had established a sensual, slightly curved design vocabulary, this new task chair range I was commissioned to develop, São Paulo, followed the same language. But architects and planners who usually decide about the acquisition of office furniture have a traditional predilection for “minimalist”, linear, austere designs. So the goal in the creation of the São Paulo line was to adhere to sinuous, flowing shapes, proving at the same time that this can result in a clean, essential and simple product.

To do so, I chose a clear cut, simple silhouette for the backrest frame that is slightly pointed at the top. Its cross-section consists of two curves and has only two (rounded) corners.

Therefore the resulting volumes consist not of flat, but only convex surfaces. All transitions are carried out as curvature continuous blends. All surfaces were modeled using class A, single span surfacing techniques. The same was applied to all the main components and produced the desired organic, almost “liquid” look.

The net material, as well as the cushioned back, are neatly and tightly fitted into the back frame structure, virtually merging them to one unified element.

All controls are incorporated flush into the lower seat base.

No protruding knobs or levers are disturbing the integrated, homogeneous look.

The result is as simple as a high performing, ergonomic swivel chair can get. Yet it stays true to a distinct, sensual, continuously flowing and organic expression.

Novedge: Can you talk about your process in creating these pieces?

Norbert Geelen: I hardly ever approach a new client with a complete design.

I prefer to first get to know as much as possible about the company, its production facilities, suppliers, history, competition, its self perception and how it's perceived by others etc.

In short: I need to understand the context of the company and its products.

It may sound very academic, but it's not like filling out a spreadsheet but more of an intuitive process, an immersion into the clients world.

This leads to a briefing or sometimes just a loose “design mission” and I start to develop my first design proposals. If possible, I try to avoid big "milestone" presentations, instead I prefer a frequent steady communication, a constant exchange of proposals and ideas.

Ideally this works like a ping-pong game: I “serve” an idea into the client's field and they hit it back to me, thus provoking my next reaction and so forth.

It is a very fluid, organic process with at times unpredictable outcome and sometimes, if necessary, the briefing or design mission can completely change during this stage.

Once the product concept has emerged or “solidified”, the parameters for the industrialization of the design will be defined in close cooperation with engineers and/or third party suppliers. This phase is often decisive for the end result and I cannot stress enough how important it is for the designer to get involved in this thoroughly.

Therefore, apart from an understanding of manufacturing cycles, the quality of CAD files I produce and transmit to engineers and the ability to work with 3D exchange file formats I get back from them becomes really important.

Usually I try to define all design related (visible or touchable to the user) surfaces including the main draft angles, ribs etc. These surfaces then serve as reference or will be directly integrated into the construction CAD/CAM files created for tooling or other production processes.

Novedge: Do you have a "design philosophy"?

Norbert Geelen: “Everything should be made as simple as possible, but not simpler.” Albert Einstein (supposedly) once said. I love this quote as a guideline to design, because it seems a strict rule, but at the same time leaves a lot of room for interpretation.

It describes a distinct way of thinking, but it’s not dogmatic about how to implement it.

I understand the wish for simplicity in design as the aim to communicate clearly: take away the unnecessary, the distracting bits, but don't cut to the flesh, don't touch the substance, the meaningful parts.

It is not about reduction to the minimum which to me is a form of impoverishment.

It is, quite the opposite, an enrichment of content by means of concentration and purification: a process of “distillation”.

At the end of this process the product will have more character, more impact and more expression than before.

Novedge: What software do you use?

Norbert Geelen: Maybe it is because I am somewhat of a geek for CAD and 3D software in general that I am always looking out for new additions to my modeling/visualization workflow.

Therefore my software setup and workflow are in constant evolution.

But there is one constant element that forms my CAD “software hub” that other tools relate to, and that is Rhino 3D.

I love the possibility to enhance its already impressive feature set by scripts and plugins.

An example for this would be Autodesk's T-Splines plugin that bridges the gap between subdivision- and nurbs-surfaces. This is perfect for quick preliminary CAD sketches and the modeling of "non engineered”, soft surfaces, as for instance upholstery.

Another important extension in modeling functionality is Virtual Shape Research's VSR Shape Modeling plug-in which greatly enhances Rhino's surfacing abilities focusing on the creation and manipulation of automative quality Class A surfaces.

It is still a fairly young product, new tools and functions are added constantly and the developers are very responsive.

I heavily relied on the combination of Rhino and VSR for the creation of the aforementioned São Paulo line of task- conference- and partner chairs.

Novedge: If you could go back in time, what would you say to your younger self before embarking in your current career?

Norbert Geelen: “Do or do not… there is no try.” Yoda

Novedge: What innovations do you see in your field now or in the future?

Norbert Geelen:As I find it hard to make meaningful predictions in a fast-changing world, I will limit myself to talk about current innovations which obviously should give a hint of what will happen in the near future too. Through the wide accessibility and affordability of modern CAD tools, a level of complexity and sophistication of the product development process once exclusive to large multinational corporations like the automotive sector has trickled down into all kinds of industries. The requirements for high quality surfacing is spreading into more and more fields of consumer products.

Rapid prototyping is replacing traditional model-making on a large scale. This obviously affects the work of industrial and product designers. While it has never been as easy and cheap to equip yourself with powerful hardware and software to tackle these challenges, the technical requirements of a designer's skills are more demanding than ever: high quality 3D CAD modeling and file exchange, a deep understanding and consideration of the production processes, the ability to flexibly collaborate and communicate with experts of ever more disciplines, to name a few.

These may only be extensions to the qualifications and abilities always requested from designers, but the technical standard is surely rising. And this may not affect all industrial designers yet, but it applies to more and more of them. Be prepared and you will have a profound degree of influence and control of your design and all its facets. Ignore the changes and someone else will make these decisions for you.

See all of Norbert's work on his website.

Are you a Rhino user? Join Rhino Jungle, the online community for all users and fans of the McNeel products, plug-ins, and complementary products.

Also in NOVEDGE Blog

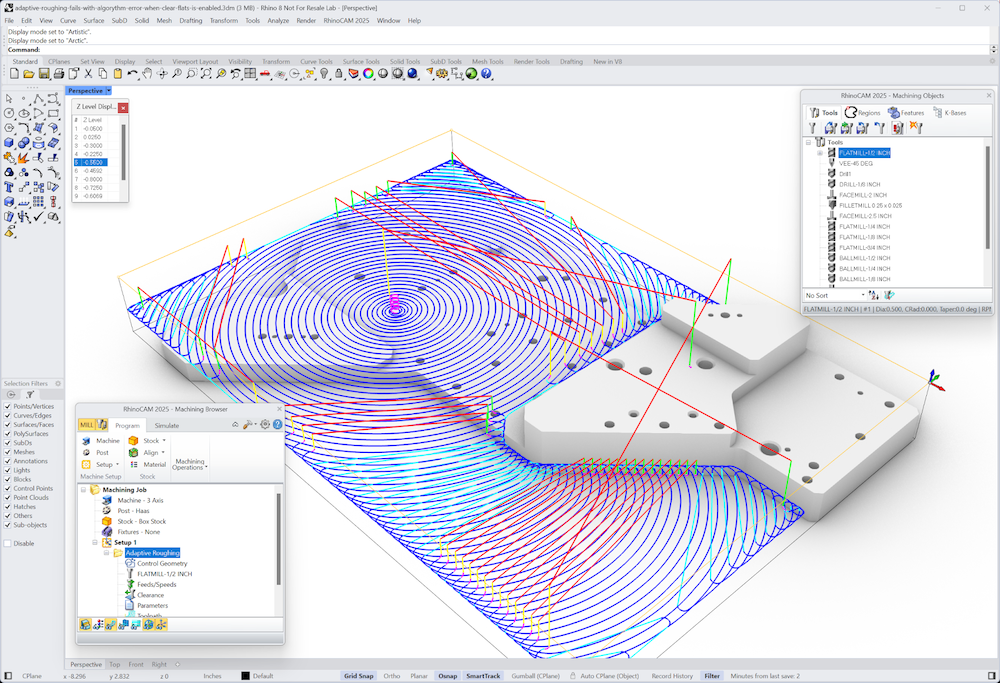

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read More

Maximize Your Architectural Workflow with VisualARQ 3's New Guides Feature

January 30, 2025 5 min read

Read More

Introducing V-Ray 7: Transforming Creative Workflows in Maya and Houdini

January 28, 2025 7 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …