Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Unlocking Micron-Level Precision: Advanced DraftSight Techniques for High-Tolerance Design

June 30, 2025 5 min read

Brief Introduction

Digital fabrication, miniaturized electronics, and high-tolerance machining have driven CAD professionals to chase **micron-level accuracy** far beyond traditional drafting expectations. The following methods focus on granular control of geometry, annotation, and verification inside DraftSight, allowing designers to meet escalating precision requirements without sacrificing productivity.

Optimize Object Snaps (OSNAP) and Snap Overrides

Every geometric decision starts with how confidently the crosshair locks onto critical endpoints, midpoints, and tangencies. Activating the classic modes—End, Mid, Perp, Tangent, Center—from the Status Bar is only the entry level. An expert will curate a lean running OSNAP set that reflects the drawing’s intent, avoiding visual clutter and “snap-itis.” When a single, rare target is needed, the SHIFT+right-click override displays the entire palette, ensuring the base running set remains optimized.

The visual feedback for snapping is governed by the APERTURE variable, which defines the box around the crosshair used for target acquisition. Reducing its size to values between 5 and 8 pixels prevents accidental grabs on dense layouts. Pair that with increasing LU_PREC and the angular DSETTINGS precision to five or six decimal places so DraftSight can internally differentiate relationships that appear coincident at coarse settings but diverge by fractions of a micron.

Once linear accuracy is secured, POLAR tracking refines angular control. Set the POLAR increment to 15°, 30°, or custom micro-increments like 7.5° when designing miniature gear teeth where pitch errors translate to immediate mechanical backlash. Together, OSNAP plus POLAR closes the positional and rotational loop, letting the designer “feel” when the cursor is magnetized to an authoritative location.

- Running OSNAP set: tailor End, Center, Intersection for mechanical fixtures; Mid, Perp, Tangent for tubing layouts.

- APERTURE tuning: smaller values for dense semiconductor masks, larger for civil site plans.

Apply Parametric Constraints for Rule-Driven Geometry

Locked snaps establish precise placement once, but iterative design demands that relationships stay intact across revisions. DraftSight’s parametric engine excels here, combining Geometric and Dimensional Constraints for a glue-like behavior among elements. Begin by applying Geometric Constraints such as Parallel or Coincident on skeletal construction lines; this captures design intent rather than frozen coordinates. Dimensional Constraints then inject explicit numbers—shaft diameters, slot widths, or lens focal distances—directly into the Parameters palette.

Managing dozens of individual constraints can overwhelm even seasoned users. Organizing them into Constraint Groups allows bulk enable/disable operations during provocative redesign sessions. For example, switch off the perpendicular group, reorient a series of ribs to pursue weight reduction, then reactivate constraints to re-lock orthogonality. Teams working on shared part families benefit immensely from constraint templates. Export a mature scheme from one project, import it into a fresh file, and the baseline relational rigor is instantly established—promoting **consistency across the enterprise**.

The true power surfaces when a single numeric value propagates through derived equations. A lead screw pitch variable can feed thread profiles, nut lengths, and anti-backlash spring cavities. Editing that parameter instantly pushes the updated pitch everywhere, eliminating hidden tolerance traps. The model behaves as a living formula where geometry is a visible output, not a fragile arrangement of lines.

- Keep driving dimensions in whole-number units where possible; reserve high-precision decimals for final locks.

- Prefix global variables with a project tag (e.g.,

MIC_Pitch) so cross-file references remain unambiguous.

Leverage Layer Filters, Lineweight Control, and Property Overrides

Visual discipline is as important as numerical discipline. DraftSight allows hundreds of layers, yet uncontrolled growth turns model space into a kaleidoscope instead of a precision tool. Dynamic Layer Filters use wildcards, colors, or plot states to isolate just the construction geometry needed right now. Typing “*-CONST*” narrows visibility to scaffolding lines, ensuring object snaps ignore decorative hatches or logos that could pollute accuracy.

Next, bring depth to the drawing with true-weight plotting lineweights. Engineers sometimes default to ByLayer 0.13 mm lines, only discovering during micro-machining that a 0.25 mm visual stroke masked a collapsible rib. Setting lineweights in their final printed thickness early highlights any tolerance overlaps, while also conveying priority—thin construction lines, medium datum frames, bold finished edges.

Layer States Manager stores ensembles such as “Draft,” “QA,” and “Publish.” During concept stages, thick lines and bright colors emphasize flow; when shifting to QA, lineweights slim down, hatch transparencies rise, and constraints become visible. Publishing loads the ISO-compliant pen table to external suppliers. All transformations occur without permanently altering layer definitions, thereby safeguarding the single source of truth.

Occasionally a critical tolerance boundary must stand out without the administrative overhead of a new layer. Property Overrides let a designer color that polyline neon orange or double its weight temporarily. Because the override is local, the underlying layer remains clean, preserving export filters that depend on the original setup.

Utilize Advanced Dimension Styles & Annotation Scaling

When the geometric skeleton is rock-solid, annotation must mirror that certainty. DraftSight’s DimStyle manager supports ISO and ANSI standards, but precision manufacturing transcends stock settings. Fine-tune arrowheads to 1.0 mm maximum for densely packed micro-optical assemblies; shrink offset distances so extension lines do not crowd adjacent tolerances. More importantly, lock linear precision to four or five decimal places and enforce unit consistency with prefixes or suffixes.

Turning on Associative Dimensions means the diminished risk of mismatched callouts: change the bore diameter, and diameter symbols, tolerances, plus the callout in the title block update automatically. This live link removes tedious manual audits before release.

Annotation Scale safeguards readability across sheet sets hosting multiple viewport scales. A 50:1 detail of a microfluidic channel should display text at the same physical height as a 1:1 overall layout. Instead of duplicating dimensions per viewport, Annotation Scale tags each dimension and DraftSight scales them elegantly.

Manufacturing partners crave unambiguous tolerance display. Activating the Tolerance dialog inside DimStyle allows limit and deviation formats. Instead of ±0.005, tolerance can appear as 10.000 / 9.995, aligning with CNC controller expectations. Incorporating these details into DimStyle ensures every new dimension inherits the same manufacturing rigor by default.

Execute Drawing Validation and Comparison Workflows

All previous techniques are preventive; validation is detective. Before handing off to tooling, run the Audit and ValidateDraft commands. These scan for zero-length entities—often artifacts from trimmed splines—and malformed polylines that can crash CAM post-processors. Gaps smaller than modelspace grid spacing are flagged, revealing invisible tolerance killers.

When revisions pour in, DRAWINGCOMPARE overlays two DWG files, color-coding additions, deletions, and modifications. Set the threshold to 0.0001 mm so even subtle shifts in locator pin diameter are highlighted. The interface outputs a third DWG layer snapshot showing the delta, making review meetings data-driven rather than guesswork.

Automating error reports accelerates team throughput. From the Batch Print/Export dialogue, compile a folder of in-process files, run ValidateDraft, and funnel the flagged entities into a CSV that quality engineers parse downstream. This pipeline integrates with PLM systems, stamping each revision with a “Clean” or “Requires Fix” metadata tag.

Finally, save a Clean Copy using DWG-CLEANUP. This strips proxies, purges unused layers, and flattens annotation scales so the published model is an immutable precision snapshot. Vendors no longer fear hidden dynamic blocks or version-specific proxies that distort geometry on import.

- Audit frequency: after each major geometric revision and before batch plotting.

- Comparison threshold: tighten progressively as the design approaches release.

Brief Conclusion

Achieving granular DraftSight accuracy is not a single command but an ecosystem of complimentary habits. Real-time capture through optimized OSNAP ensures coordinates originate correctly. Parametric constraints enforce relational logic, preventing drift as designs evolve. Layer discipline and meticulous dimension styles guarantee that what you see is what the fabricator receives. Validation commands close the loop, catching anomalies that slip past even the sharpest human eye.

Adopt these techniques sequentially. Begin by sharpening snapping practices, then introduce low-overhead constraints, layer filters, organized dimstyles, and finally a rigorous validation cadence. Each layer reinforces the previous until the entire workflow delivers repeatable micron-level accuracy—no heroic all-nighters, just systematic excellence.

Also in Design News

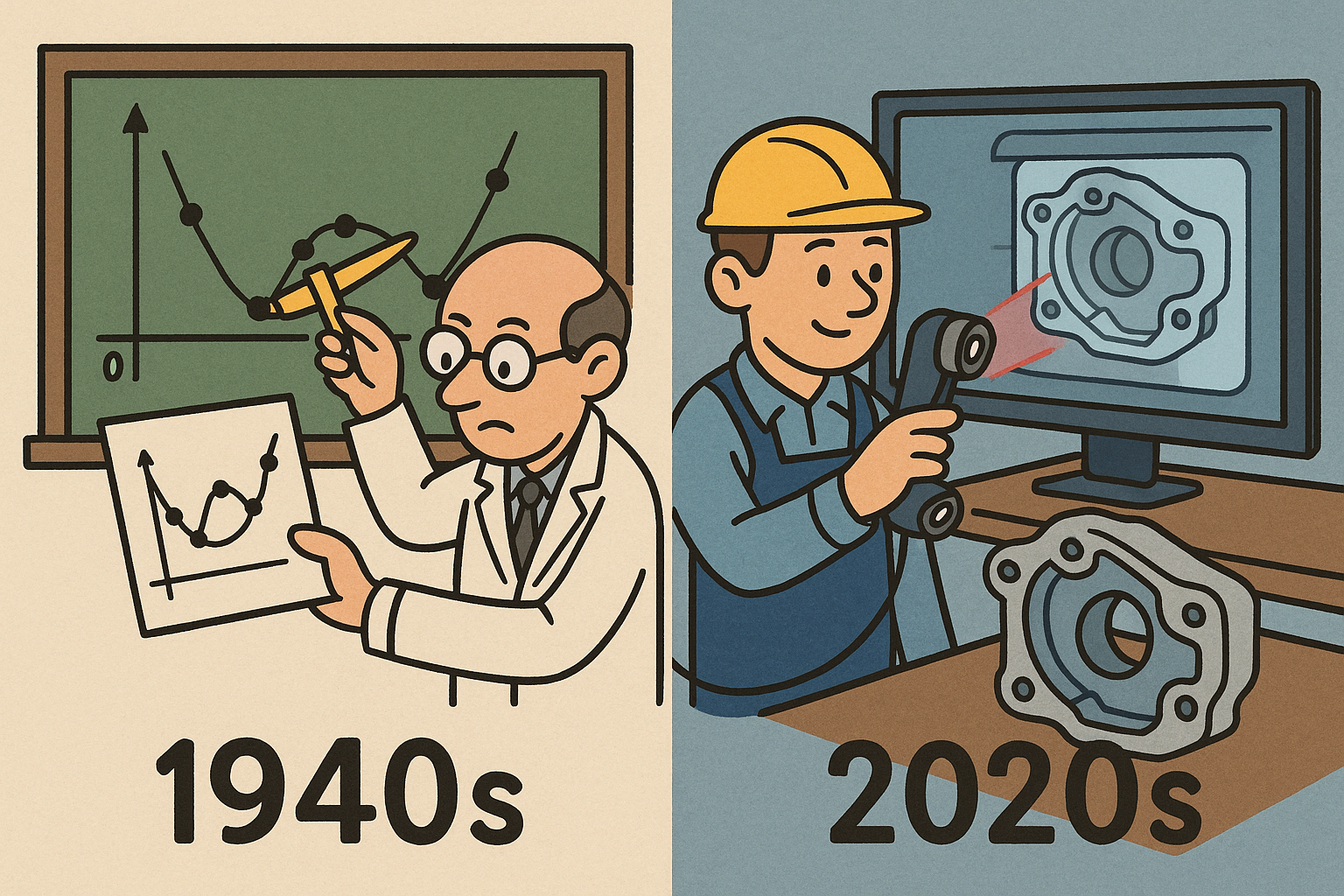

Design Software History: Scan Fitting: Mathematical Foundations and Industrialization (1940s–2020s)

March 05, 2026 14 min read

Read More

Performance-by-Construction: Differentiable Wave-Ray Design and DfAM for Geometry-Driven Acoustics

March 05, 2026 17 min read

Read More

Cinema 4D Tip: Render Region: Final‑Quality Crops for Faster Iteration

March 05, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …