Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Scan-to-CAD Workflows: Precision Capture, Feature-Preserving Reconstruction, and Tolerance-Aware Parametric Rebuilds

January 02, 2026 12 min read

Introduction

Why scan-to-CAD demands both precision and design intent

Reverse engineering has matured from a series of disconnected steps into a disciplined pipeline where each decision—sensor choice, alignment strategy, surface reconstruction, and parametric rebuilding—affects all downstream outcomes. The fastest route from reality to manufacturing-ready models is not merely about collecting dense points; it is about capturing the right points, cleaning them deterministically, enriching them with uncertainty and provenance, and rebuilding models that enshrine constraints, tolerances, and intent. This article walks through an end-to-end flow from reality capture to clean point clouds, to watertight meshes and CAD-friendly surfaces, and finally to parametric models with annotated product and manufacturing information. Along the way, we emphasize the importance of measurable quality gates, **feature-preserving reconstruction**, and **tolerance-aware modeling**, while acknowledging the accelerating role of **AI-assisted automation**. The goal is pragmatic: provide recipes that reduce rework, increase traceability, and keep the digital thread intact from acquisition to production. Whether you are digitizing heritage parts, validating vendor tooling, or building simulation-ready geometry for engineering computation, these practices transform noisy measurements into assets that scale across design updates, visualization, and additive or subtractive manufacturing.

From Reality Capture to Clean Point Clouds

Selecting capture modality and planning for occlusions

The right capture modality is a function of geometry, material, and scale. For small, high-detail parts—knurled knobs, dental appliances, micro-textures—structured light excels with millimetric fields of view and sub-50 µm precision. For large interiors, plant scans, and civil assets, laser/ToF LiDAR wins on reach and efficiency, maintaining robust returns over tens of meters with stable angular accuracy. Photogrammetry remains the cost-effective champion for large coverage outdoors, and with strong textured scenes it can approach sub-millimeter reconstruction on modest baselines. The material question is equally decisive: glossy, transparent, and dark materials will confound many sensors, demanding **cross-polarization**, **developer spray**, or high dynamic range exposure bracketing. Planning is about occlusion management: orchestrate **multi-azimuth passes**, employ a turntable for small parts to guarantee complete coverage, and leverage props or temporary fixtures to expose hidden features safely. Ultimately, you mitigate rework by pre-visualizing line-of-sight, deciding on **coverage redundancy** where alignment will benefit from loop closure, and logging environmental conditions—temperature, vibration, lighting—that can bias results. A pragmatic checklist helps: define critical features and tolerances, mark must-see regions, decide on target strategy, and set capture density targets appropriate for downstream meshing and fitting rather than raw impressiveness.

- Structured light: small FOV, high precision, sensitive to ambient light.

- Laser/ToF LiDAR: long range, robust in large spaces, lower per-point precision.

- Photogrammetry: low-cost, texture-dependent, scalable outdoors.

- Mitigate reflectivity with cross-polarization or temporary matte coatings.

- Plan loop closure routes to stabilize global alignment.

Controlling accuracy at the source

Control the error budget where it matters most—during acquisition. Begin with documented calibration routines: intrinsic and extrinsic calibration for multi-camera rigs, scale verification for structured light systems, and periodic boresight checks for LiDAR. Employ **coded targets** and **scale bars** to establish a metrological scaffold that resists drift, and keep them distributed across volumes and depth layers to avoid planar degeneracy. Coverage strategies matter: a **turntable** ensures uniform azimuth sampling and supports robust pose graph loops; handheld passes should vary elevation and orbit radius to prevent alignment from failing due to repeated viewpoints. For gleaming polymers or polished metals, use **cross-polarization** to suppress specular noise while preserving diffuse signal that tracks surface shape, or apply reversible matte sprays with known thickness so thickness can be compensated when deriving absolute dimensions. Record every step: sensor serials, calibration timestamps, ambient temperature, and vibration notes, then tie them into the dataset metadata. This provenance not only accelerates troubleshooting when residuals inflate but also underwrites claims of compliance with standards like **VDI/VDE 2634**. The cleanest point clouds are earned long before the first ICP iteration; they are engineered by constraining error growth at the source.

- Run calibration daily or per setup; store calibration matrices with versioning.

- Distribute scale bars and targets in 3D, not just within a single plane.

- Use multi-height, multi-radius orbits to diversify baseline geometry.

- Log environmental data for uncertainty modeling.

Registration and preprocessing that preserve features

Registration should flow from robust initialization to refinement without falling into local minima. Seed alignments with **FPFH/SHOT** features or robust RANSAC-based correspondence to obtain plausible initial poses. Refine with pairwise ICP variants chosen to match local geometry: **point-to-plane** offers faster convergence on smooth regions, while **GICP** balances anisotropic covariances and can better respect edge neighborhoods. Promote these pairwise links into a **pose graph** and solve with loop closure to distribute drift globally, preferring robust cost functions (Huber, Cauchy) to suppress outliers. Preprocessing must respect features: use **statistical outlier removal** to prune spurious returns, but cap thresholds by scale-aware estimators to avoid erasing fine fillets or chamfers. Apply **bilateral filtering** or normal-aware denoising to suppress high-frequency noise while preserving curvature extrema; orient normals through MST traversal or spanning tree methods that avoid flips across thin walls. Voxel-grid downsampling accelerates the pipeline, but preserve edges with adaptive voxel sizes or feature-weighted sampling. The leitmotif: smooth noise, not geometry. Each cleanup action should be traceable, parameterized, and reversible so you can re-run with different tolerances if reconstruction later reveals underfitting around sharp edges.

- Feature seeding with FPFH/SHOT improves convergence basins for ICP.

- Use pose graph optimization with robust loss and explicit loop closures.

- Normals: orient via MST traversal; validate with view-consistency checks.

- Downsample with edge-aware or curvature-weighted strategies.

Data structures, acceleration, and quality gates

Neighbor queries dominate runtime in registration and filtering; accelerate them with **KD-trees** for static clouds and **permutohedral lattices** for high-dimensional bilateral filtering where color or intensity guides smoothing. Multi-resolution pyramids enable **coarse-to-fine alignment**, tackling large misalignments at low resolution and progressively tightening at high resolution. Offload heavy hitters—ICP, nearest-neighbor searches, and even Poisson solvers—to GPU using CUDA or Vulkan compute for order-of-magnitude speedups on dense scenes. Throughout, embed quality gates: track per-point uncertainty (propagated from sensor models or empirical residuals), store the **scanner pose graph** with residual statistics, and capture environmental metadata. Commit to standards: verify compliance to **VDI/VDE 2634** or relevant ISO norms and maintain a rolling **measurement uncertainty budget** that aggregates calibration drift, environmental influence, and numerical conditioning. Quality gates are green only when metrics and metadata agree: low residuals without provenance is not acceptable, and pristine metadata with high residuals is a stop sign. By combining competent data structures, acceleration tactics, and metrological discipline, you turn raw, variable-quality captures into **clean point clouds** that carry their own uncertainty and history forward.

- Use KD-trees for neighbor queries; consider voxel hashing for massive scenes.

- GPU-accelerate ICP, correspondence search, and Poisson reconstruction.

- Record uncertainty per point and per registration edge in the pose graph.

- Gate deliverables on both residual metrics and standards compliance.

Surface Reconstruction: From Points to Watertight Meshes and CAD-Friendly Patches

Choosing meshing strategies that honor intent

Not all meshing algorithms optimize for the same outcomes. When you need watertightness and global smoothness, **Poisson surface reconstruction** is a proven workhorse: it integrates oriented normals into an implicit field and extracts a manifold iso-surface that closes small gaps naturally. If edge fidelity trumps watertightness—think thin sheet metals, vents, or sharp creases—**ball-pivoting** follows data more literally, preserving ridges and sparse regions where Poisson might over-smooth. For heterogeneous sampling densities, **Delaunay-based methods** adapt to local point density and can respect sharp features when coupled with edge-aware weighting or protecting constraint edges. The trick is to match algorithm bias with design intent: consumer-grade scans of organic shapes benefit from the regularization of Poisson, while engineered parts often demand feature-preserving strategies with explicit crease constraints. Edge-aware weighting, anisotropic smoothing, or confidence-based blending lets you enjoy both: smooth in nominal regions, crisp along functional edges. Pipeline hygiene matters here too: ensure consistent normal orientation and appropriate scale normalization prior to reconstruction to avoid topological inversion or bloated kernels. Finally, parameterize reconstruction for replayability; small changes in depth or octree levels produce measurable changes in edge roll-off that should be justifiable and repeatable.

- Poisson reconstruction: watertight, smooth, may blur sharp features if not guarded.

- Ball-pivoting: edge-faithful, sparse-data friendly, can leave holes.

- Delaunay/advancing-front: adaptive density, supports constrained edges.

- Use confidence or normal variance as weights to temper over-smoothing.

Primitive detection and blend-aware segmentation

Capturing design intent begins with recognizing primitives that encode manufacturability: planes, cylinders, cones, spheres, and tori. Robust **RANSAC** over oriented points provides initial hypotheses resilient to outliers, which you refine with non-linear least squares for sub-voxel convergence. **Region growing** leverages local normal similarity and curvature to expand primitive domains without jumping across fillets. Where surfaces transition—fillets, blends, and fairings—consult mean curvature and **shape index** to identify blend corridors. Segment the mesh into charts with consistent curvature signatures, then classify each chart as analytic or freeform. This segmentation enables mixed reconstructions where analytic patches are fitted as true primitives while adjacent freeform zones remain splines. Primitive unions and intersections reveal sketch planes and feature axes; preserving these across segmentation preserves not just geometry but also **manufacturing intent** such as drilling directions or milling setups. When multiple candidates overlap, prefer the one with the strongest support and lowest residual, but retain alternates in metadata for design what-if analysis. The result is a mesh labeled not just by triangles but by meaning—a foundation for CAD rebuilding that respects how the part was likely made.

- Seed primitives with RANSAC; refine with Levenberg–Marquardt fits.

- Grow regions with curvature- and normal-consistency thresholds.

- Use shape index maps to isolate blends and transitions.

- Attach axes and datum planes to primitives for downstream constraints.

Freeform surfacing with continuity and sharp features

Where analytic patches stop, freeform must begin—and it must be disciplined. Fit **B-spline/NURBS** patches over segmented charts using energy functionals that minimize point-to-surface distance while regularizing fairness via thin-plate or curvature terms. Enforce **G1/G2 continuity** along patch boundaries by constraining tangent and curvature strips during optimization, or by solving multi-patch systems that share control rows across seams. For organic models captured from SubD designs, leverage **SubD-to-NURBS** conversion to obtain high-quality, low-degree surfaces that retain the original flow while enabling parametric edits. Sharp features deserve explicit protection: detect creases via **normal discontinuities** or dihedral thresholds, then lock those edges during mesh optimization and surface fitting. Fillets are not just “whatever the scan says”; rebuild them as **parametric arcs** or variable-radius blends, tracing center curves and roll-off profiles so that later edits remain manufacturable and analyzable. The pay-off is a hybrid surface stack where analytic primitives provide anchors, freeform surfaces deliver aesthetics and aerodynamics, and crease constraints keep functionally critical edges intact through remeshing, thickening, and Boolean operations.

- Use fairing energies to balance fit error and smoothness.

- Impose G1/G2 continuity with shared control structures.

- Protect creases; rebuild fillets with explicit radius laws.

- Convert SubD to NURBS for editable freeform in CAD ecosystems.

Defect handling and validation that closes the loop

Real-world scans come with gaps, spikes, and topology glitches. Fill holes with curvature-guided patches that extrapolate along principal directions rather than naïve triangulation; avoid spanning across intended vents or slots by constraining fills to labeled hole regions. Resolve self-intersections via robust Boolean or remeshing steps, and collapse non-manifold edges by local re-tetrahedralization or edge flipping. For simulation readiness, retopologize into analysis-friendly meshes: quad-dominant meshes for shell analyses, well-shaped tetra or hexa meshes for volumetric solvers, all while respecting boundary layers and thickness. Validation is not a ceremony; it is a quantitative contract. Compute **Hausdorff** and RMS deviation maps between the reconstructed surface and the point cloud; chart curvature deviation histograms to see whether fillets and corners match manufacturing-critical curvature. Run **local thickness checks** to confirm that cladding, ribs, or hollow sections are plausible for the intended process—additive, casting, or sheet metal. Finally, establish acceptance thresholds tied to function: if a sealing surface must hold ±0.05 mm flatness, ensure the deviation map and fit residuals support it. Only promote surfaces downstream when the metrics and tolerances align with functional requirements.

- Use curvature-aware hole filling; avoid bridging intentional openings.

- Eliminate self-intersections and non-manifolds before export.

- Retopologize for analysis with boundary-layer fidelity.

- Gate deliverables on Hausdorff/RMS and curvature deviation limits.

From Meshes to Parametric Models: Rebuilding History, Constraints, and PMI

Feature recognition that reconstructs the model tree

Parametric rebuilding succeeds when you re-discover the design story: what sketches, what operations, and in what order. Begin by inferring **sketch planes** from dominant planar regions and symmetry hints; project profiles from silhouette and intersection curves, then classify operations: **extrude, revolve, sweep, loft**. Detect regularity: linear and circular **patterning**, mirror symmetry, and repeats reduce model complexity and stabilize edits. Leverage the primitive-labeled mesh to locate bosses, pockets, through-holes, counterbores, chamfers, and fillets; cluster hole axes to infer standardized patterns and thread candidates. Map transition surfaces to fillet features rather than leaving them as anonymous freeform; parametric fillets carry radius laws and tangent propagation that future designers expect. Chronology matters: build base features first, then add detail, keeping references to datums and primary coordinate frames that match manufacturing setups. As the tree takes shape, you transform a mesh into a maintainable model with **replayable history**, where dimension edits ripple predictably and assemblies reference stable faces instead of fragile triangulations. This is how you turn geometric fidelity into engineering agility.

- Infer sketches from planar charts and robust silhouettes.

- Classify operations into extrude/revolve/loft/sweep from profile-surface relations.

- Detect patterns and symmetry to compress the feature tree.

- Elevate blends and chamfers into native parametric features.

Constraint and dimension inference that respects function

A good parametric model is constrained just enough—no more, no less. Derive **parallelism**, **perpendicularity**, **concentricity**, and **tangency** from primitive relationships, reinforcing them in sketches and between features. Estimate smart dimensions from dominant frequencies in edge-to-edge distances: histogram distances between candidate hole centers to reveal pitch, or between ribs to reveal regular spacing. Where gauge features or inspection datums exist, lock them in early: datums stabilize the entire model. Convert freeform fits into editable control networks with dimension proxies—arc lengths, chord heights, or curvature comb bounds—so designers do not have to guess the original intent. Tread carefully with over-constraints; promote soft constraints first and escalate to hard constraints after confirming stability via solve diagnostics. When ambiguity arises, consult the **uncertainty budget** and entrust humans to adjudicate intent. The aim is to produce dimensioned sketches that capture how the part is made and measured, not merely how it looks. Proper constraint inference reduces future regeneration failures and aligns the model with inspection and assembly logic.

- Apply geometric constraints from primitive adjacency and axes relationships.

- Use frequency analysis of distances to propose standard pitches and sizes.

- Attach datums to stabilize model references for MBD workflows.

- Prefer soft constraints initially; promote to hard after validation.

Hybrid workflows for analytic features and freeform control

Modern products blend analytic machine features with sculpted surfaces. Embrace a **hybrid workflow**: represent bosses, pockets, threads, and standardized holes with native CAD features so downstream CAM, tolerance analysis, and simulation tools recognize them semantically. For threads, drive sizes from standards (ISO/UNC/UNF) and map scanned helixes to nominal profiles with pitch compensation derived from scan residuals. Use **reference sections**—orthogonal cuts, silhouettes, and **zebra analysis**—to guide rebuilds of freeform zones while maintaining tangent continuity at interfaces with analytic regions. Subdivide the freeform into manageable patches whose control structures align with the visual flow and manufacturing directions (e.g., mold pull or layup fibers). Anchor these surfaces to skeletons: guide curves, spine trajectories, and rail networks that encode the original designer’s scaffolding. This combination ensures analytic areas are editable and inspectable, while freeform sculpting remains methodical and constrained. For downstream durability, lock critical mating faces as references and expose high-value dimensions as parameters, allowing assemblies to update reliably as design iterations proceed.

- Use native hole/thread features; map scans to nominal standards.

- Drive freeform edits with zebra/silhouette diagnostics and guide curves.

- Align freeform patch flow with manufacturing directions and draft.

- Promote mating faces and key dimensions to top-level parameters.

Tolerance-aware modeling and automation with AI

Scans are measurements, not truth; bring that humility into the model. Propagate **scan uncertainty** into dimension ranges and maintain **deviation heatmaps** linked to each feature so engineers can see where fits are tight and where they’re indulgent. Annotate PMI with derived **GD&T** where intent is clear—flatness on sealing planes, position tolerances on hole patterns relative to datum frameworks—and mark ambiguous areas as provisional. On the automation front, **semantic segmentation** models can classify regions by feature type, while **neural SDF/implicit fields** can provide robust fitting for thin or noisy data. Learning-based normal estimation improves reconstruction in low-signal areas, particularly glossy or translucent materials where classical normals are unreliable. Keep a **human-in-the-loop**: require approvals for feature recognition, tolerance assignments, and major topology decisions; record rationales in audit logs for accountability. Automation accelerates routine actions, but explainability and traceability govern acceptance in regulated or safety-critical contexts. The synthesis of probabilistic modeling and AI-driven inference yields models that are both efficient to build and honest about their certainty.

- Attach uncertainty bands to dimensions; visualize per-feature deviations.

- Use semantic segmentation to pre-label primitives and blends.

- Fit with neural implicits for resilience to sparse or noisy data.

- Institutionalize human reviews for intent and tolerance sign-off.

Interoperability, the digital thread, and edge strategies

Durable reverse engineering lives and dies by interoperability. Maintain lineage from raw scans (**E57/LAS/PLY**) to meshes (**OBJ/STL**) to CAD (**STEP AP242/IGES/Parasolid XT**), embedding references and hashes so each derivative can be traced to its source. Keep **replayable scripts**—procedural reconstruction steps, registration parameters, surface fitting settings—under version control so results are reproducible under audit. Link model versions to inspection reports and simulation cases to preserve context across iterations. Edge cases require tactical adaptations: for occluded geometry, use symmetry inference, mirrored features, or conservative extrapolation bounded by tolerances. For highly reflective or transparent materials, apply **proxy coatings** with known thickness and correct dimensions after stripping, or use polarization strategies that isolate diffuse return. For large assemblies, adopt **tiled captures** with hierarchical reconstruction: sub-assemblies are registered locally with strong constraints, then merged globally via robust pose graphs. Hierarchical strategies also speed rework, letting teams refresh a module without destabilizing the whole. The outcome is a **digital thread** where data, decisions, and tolerances move together from measurement through design, simulation, and manufacturing.

- Preserve lineage across E57/LAS/PLY → OBJ/STL → STEP/IGES/XT.

- Store scripts, parameters, and hashes for auditable replay.

- Resolve occlusions via symmetry and intent-aware extrapolation.

- Tile large captures; reconstruct hierarchically with pose graphs.

Conclusion

Turning measurements into manufacturable intent

The most effective reverse engineering prioritizes both geometry and intent. That means selecting capture modalities that fit material and scale, constraining error at the source, and reconstructing surfaces that preserve features and continuity where performance and manufacturability demand it. From there, rebuilding parametric history and constraints converts static meshes into living models that sustain change without collapse. Quality is never an afterthought; it is governed by measurable metrics, metadata, and standards compliance that travel with the asset. Automation is raising the floor—through segmentation, implicit fitting, and learned normals—but informed human oversight remains critical for explainability and responsibility. To keep assets maintainable across redesigns, analysis, and production, invest in interoperable formats, replayable pipelines, and uncertainty-aware PMI. In practice, these principles converge into a workflow that is faster, more predictable, and more defensible than ad-hoc artistry, turning noisy reality into reliable design intelligence.

- Preserve design intent: favor primitives, constraints, and manufacturable features over raw surface mimicry.

- Couple disciplined capture with feature-preserving reconstruction: enforce quality gates with uncertainty budgets and standards.

- Automate pragmatically: accelerate with AI while keeping human-in-the-loop validation for auditability.

- Invest in provenance and interoperability: maintain metadata-rich lineage and replayable scripts for a resilient digital thread.

Also in Design News

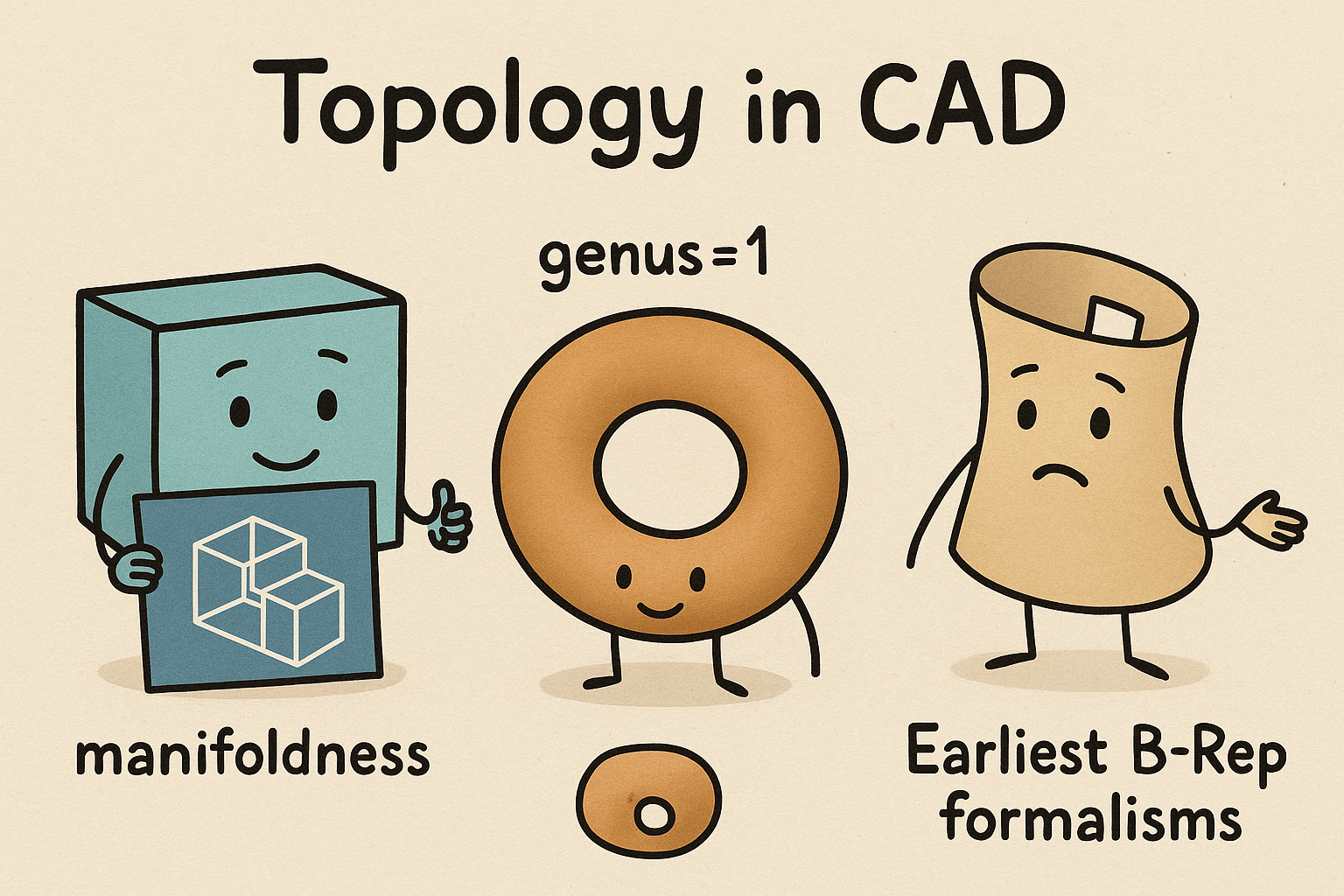

Design Software History: Topology in CAD: Manifoldness, Genus, and the Earliest B‑Rep Formalisms

January 02, 2026 14 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …