Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Rhino 3D Tip: Optimizing the Unroll Surface Command in Rhino 3D for Accurate 2D Pattern Creation

March 11, 2025 3 min read

Mastering the Unroll Surface command in Rhino 3D is essential for creating accurate flat patterns from complex 3D surfaces. Whether you're working in sheet metal fabrication, boat building, or architectural modeling, effectively unrolling surfaces allows you to translate 3D designs into workable 2D patterns for manufacturing processes. Here are some tips to help you make the most of this powerful tool:

- Ensure Surfaces are Developable: The Unroll Surface command works best with developable surfaces—those that can be flattened without distortion. Developable surfaces include cones, cylinders, and other shapes where material can be unrolled into a flat plane without stretching or compressing. Attempting to unroll doubly-curved surfaces, like spheres or complex freeform shapes, will result in inaccuracies. Use the CurvatureAnalysis command to check surface developability before unrolling.

- Join Connected Surfaces: If your model includes multiple connected surfaces that you wish to unroll as a single piece, use the Join command to combine them into a single polysurface. This maintains edge relationships and continuity in the flattened pattern, ensuring that the unrolled piece represents the 3D geometry accurately. Keep in mind that the combined surfaces must be tangent or smoothly connected for the best results.

- Use Labels and Markers: When unrolling a surface, enable the options for Labels and Explode input objects in the command dialog. Labels assign numbers to edges and vertices, which are invaluable references when reassembling the parts after cutting. Markers indicate key points like holes, seams, or alignment features, helping to ensure that the physical assembly aligns perfectly with the design intent.

- Check Surface Normals: Ensure that surface normals are consistent and pointing in the expected direction before unrolling. Surface normals indicate the "front" side of a surface. Inconsistent normals can cause the unrolled pattern to mirror or flip unexpectedly. Use the Dir command to visualize and, if necessary, flip the normals so they are consistent throughout your model.

- Validate the Unrolled Pattern: After unrolling, it's crucial to validate the flat pattern against the original 3D model. Use measurement tools like Distance, Angle, and Length to compare critical dimensions. This step ensures that the unrolled pattern maintains the accuracy required for manufacturing, reducing the likelihood of errors in the final product.

- Manage Tolerances: Adjust modeling tolerances appropriately before using the Unroll Surface command. Tightening the tolerances can improve the precision of the unrolled surface, which is especially important for high-precision applications. However, be aware that very tight tolerances may increase computation time and require more processing power.

- Handle Trims and Holes: The Unroll Surface command can accommodate trimmed surfaces and internal holes. Make sure that any trims, cuts, or holes are accurately represented in your 3D model. These features will be projected onto the unrolled surface, allowing for precise cutting or machining in the manufacturing process.

- Use Grouping for Complex Models: For complex models with multiple surfaces or components, consider unrolling surfaces in sections. Group related components together using the Group command. This approach simplifies the unrolling process and makes it easier to organize and assemble the flattened parts later on.

For more advanced techniques and software solutions, consider exploring the products available at NOVEDGE. They offer a wide range of resources, including plugins and training materials, to enhance your Rhino 3D experience.

To get the most out of Rhino 3D and tools like the Unroll Surface command, check out training resources and plugins available through NOVEDGE. Visit NOVEDGE's Rhino 3D page for more information.

You can find all the Rhino products on the NOVEDGE web site at this page.

Also in Design News

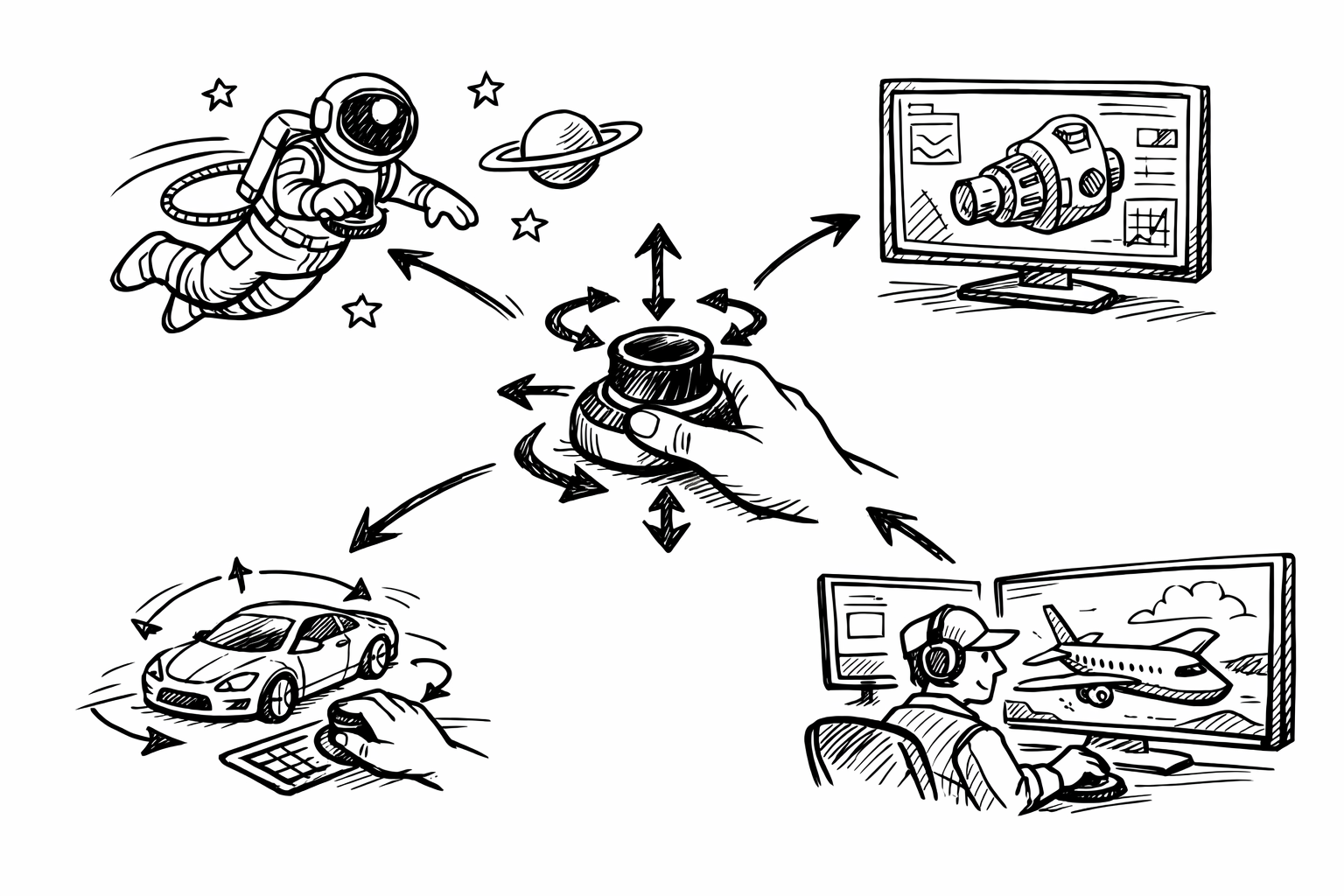

SpaceMouse as Computational Ergonomics: 6DoF Navigation for Faster, More Accurate Simulation Workflows

March 01, 2026 11 min read

Read More

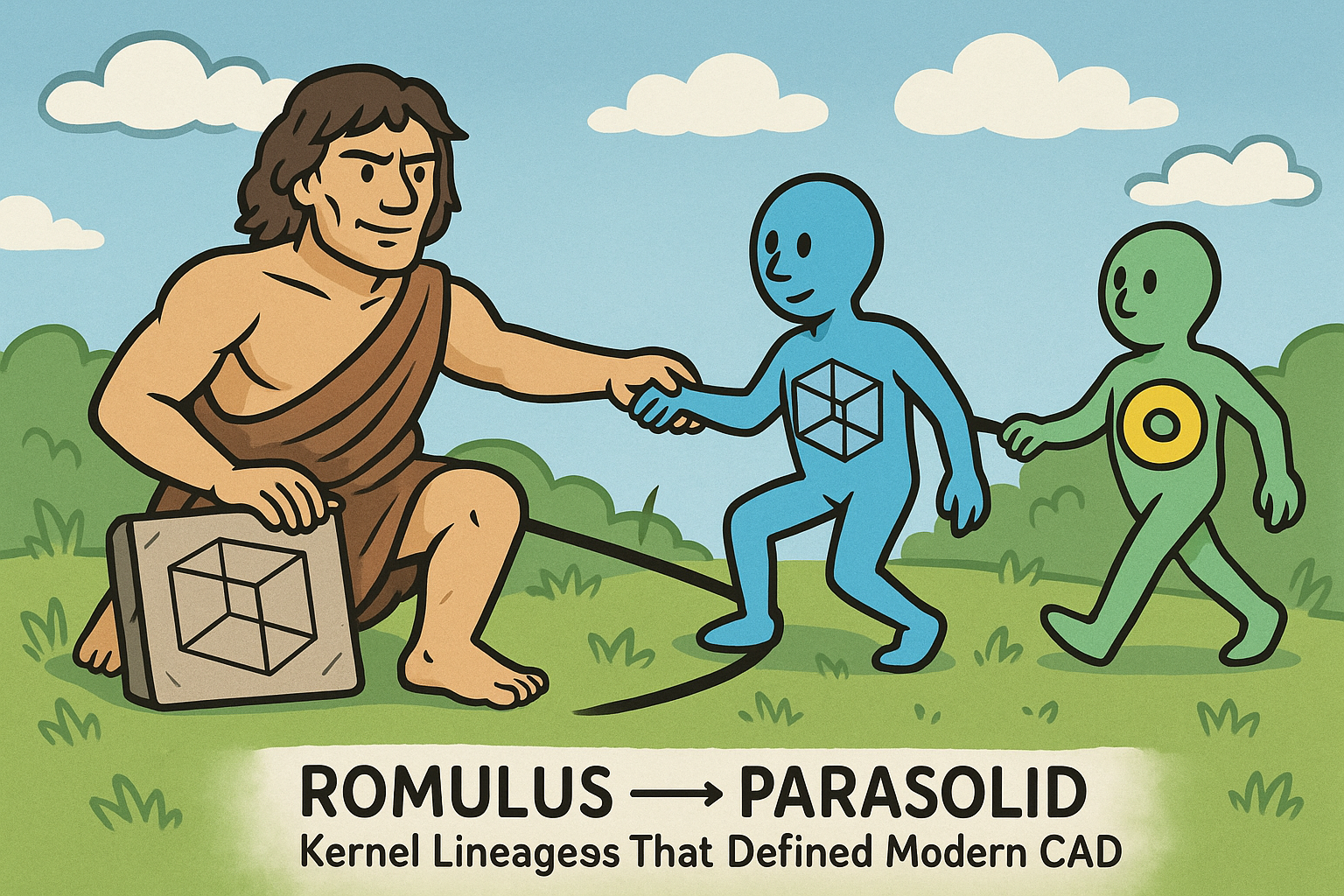

Design Software History: ROMULUS to Parasolid and ACIS: Kernel Lineages That Defined Modern CAD

March 01, 2026 13 min read

Read More

Augmented Assembly: Turning CAD/MBD into Executable XR Work Instructions for the Digital Thread

March 01, 2026 13 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …