Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Rhino 3D Tip: Maximizing Digital Fabrication Potential with Rhino 3D: A Beginner's Guide to Precision Modeling and Production Techniques

July 29, 2024 2 min read

Digital fabrication is revolutionizing the way we create and manufacture products, and Rhino 3D is at the forefront of this transformation. With its precise modeling capabilities and compatibility with various digital fabrication tools, Rhino 3D is an invaluable asset for designers, architects, and engineers. Here's a concise guide to help you get started with digital fabrication using Rhino 3D.

- Understand the Basics: Before jumping into digital fabrication, familiarize yourself with the fundamental concepts of fabrication methods like CNC milling, 3D printing, and laser cutting. Each method has its own set of design constraints and considerations.

- Design for Fabrication: When modeling in Rhino, always keep the end fabrication process in mind. This means considering material size, machine limitations, and the need for supports or scaffolding in your design.

-

Model Precision: For successful fabrication, your model must be precise. Ensure that all surfaces are closed and that there are no naked edges. Rhino's diagnostic tools like

ShowEdgesandShowNakedEdgescan help identify and fix these issues. - File Preparation: Different fabrication machines require different file formats. Common formats include STL for 3D printing, DWG/DXF for CNC milling, and AI or PDF for laser cutting. Use Rhino's export functions to save your file in the appropriate format.

- Toolpath and Nesting: In Rhino, you can use plugins like RhinoCAM to generate toolpaths for CNC milling. For optimizing material usage, nesting software can arrange your parts efficiently on the material sheet.

- Prototyping: Before the final production run, create prototypes to test the fit, form, and function of your design. This step can save time and resources by revealing any issues that need to be addressed.

- Collaboration with Fabricators: If you're not operating the fabrication machinery yourself, work closely with fabricators. They can offer insights into the capabilities of their equipment and suggest adjustments to your design if necessary.

- Post-Processing: After the fabrication process, some parts may require post-processing such as sanding, assembling, or painting. Account for these steps in your project timeline and budget.

For those interested in further enhancing their digital fabrication skills with Rhino 3D, NOVEDGE offers a variety of resources and software plugins to help you take your designs from screen to reality. Embracing digital fabrication with Rhino 3D can bring your projects to new levels of precision and innovation, enabling you to create complex and customized products with ease.

```You can find all the Rhino products on the NOVEDGE web site at this page.

Also in Design News

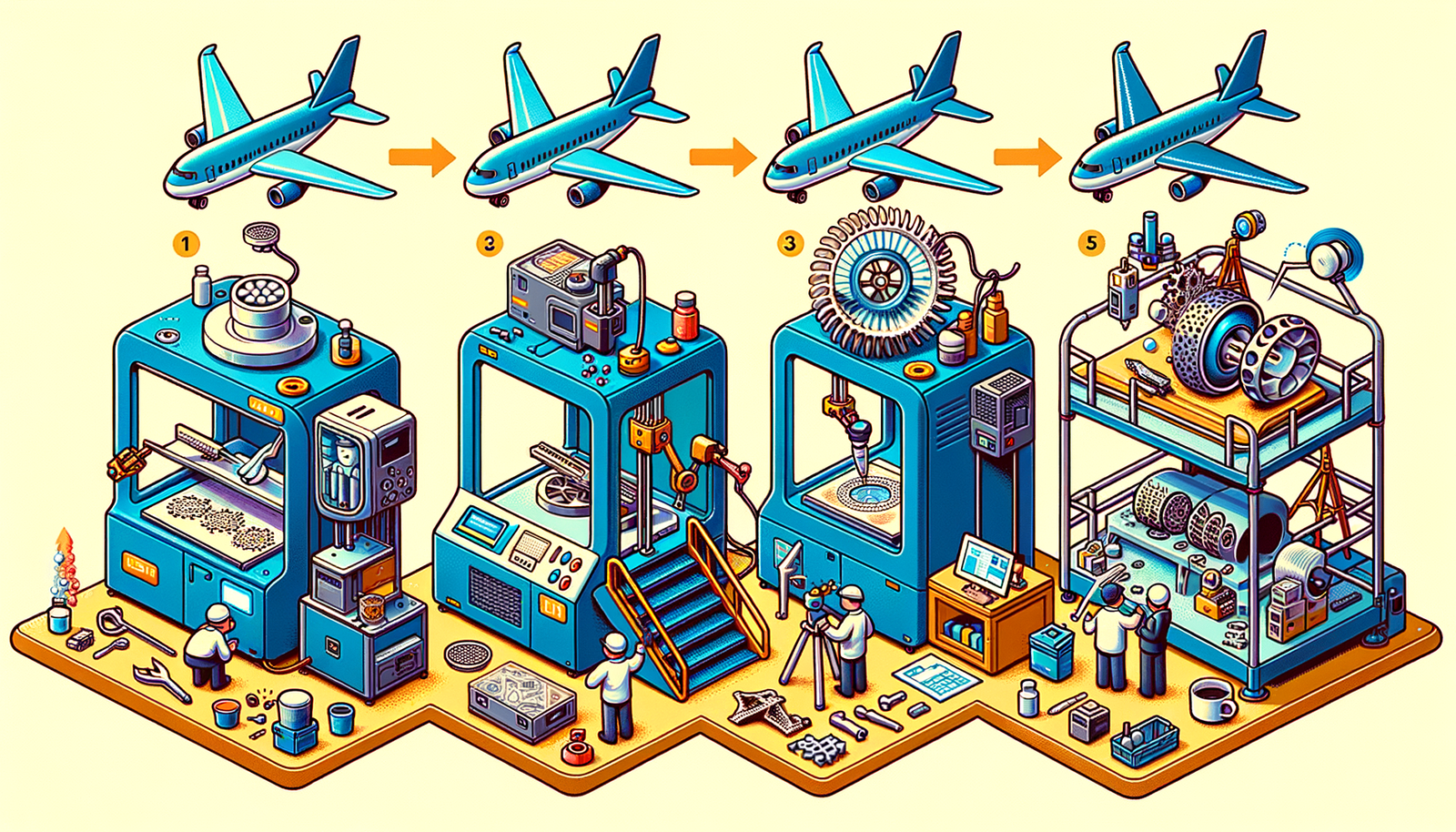

Design Software History: The Evolution of 3D Printing in Aerospace: From Prototyping to Production

November 27, 2024 7 min read

Read More

Cinema 4D Tip: Optimizing Workflow with Team Render in Cinema 4D

November 27, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …