Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

PLM and CAD Integration: Enhancing Workflow Efficiency and Collaboration in Modern Product Development

September 12, 2024 4 min read

Introduction to PLM and CAD Integration

Definition and Importance

Product Lifecycle Management (PLM) systems are comprehensive solutions that manage the entire lifecycle of a product from inception, through engineering design and manufacturing, to service and disposal. PLM provides a data backbone for product information, ensuring seamless access and collaboration across different departments and stakeholders.

On the other hand, Computer-Aided Design (CAD) software is fundamental for designing and drafting products digitally. CAD enables engineers and designers to create precise drawings, models, and simulations, which are essential for modern product development.

Integrating PLM systems with CAD is highly beneficial because it creates a unified ecosystem that enhances data consistency, reduces errors, and improves overall workflow efficiency. This integration ensures that CAD data is seamlessly managed and accessible through the PLM system, leading to better collaboration and faster time-to-market.

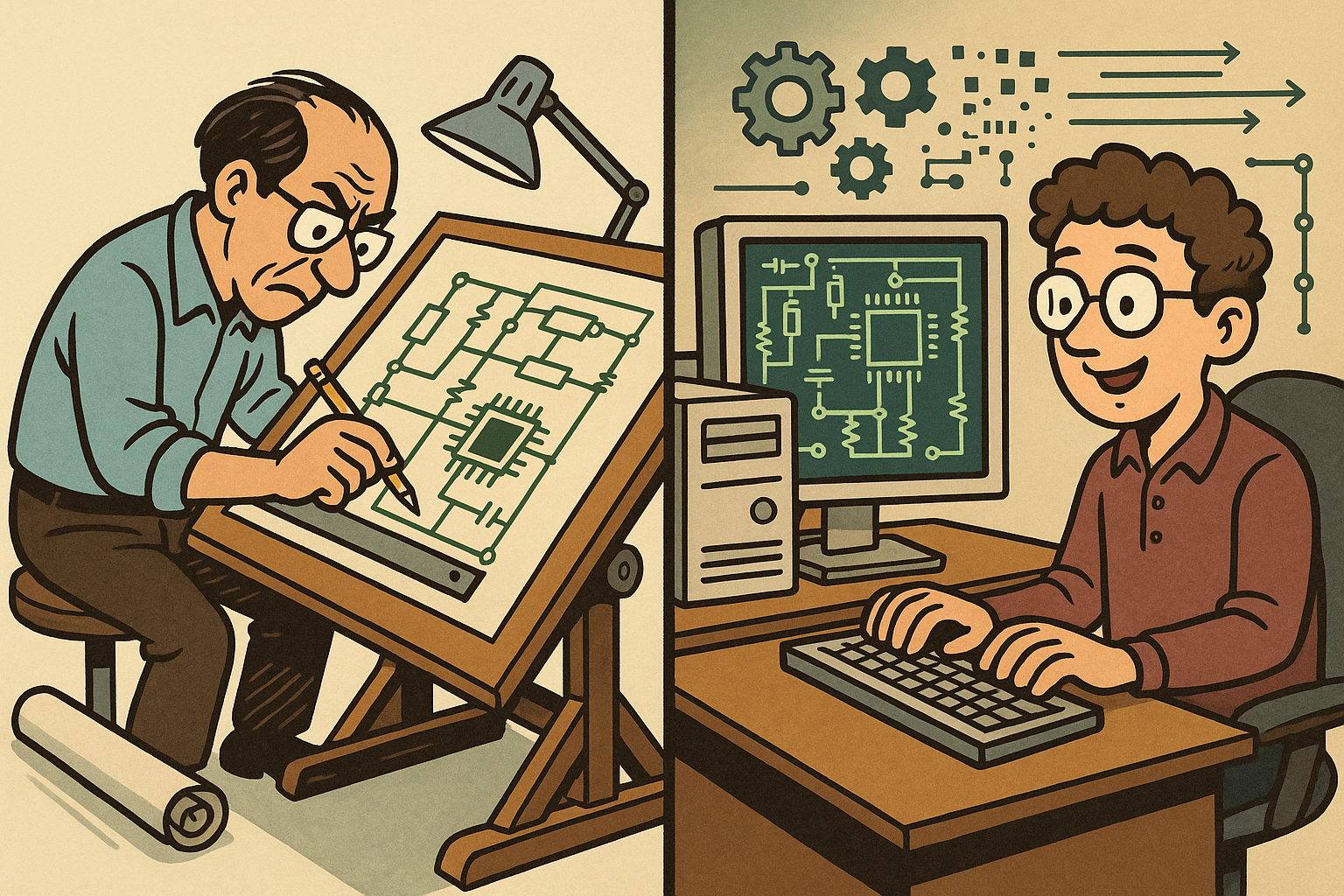

Historical Context

The concept of PLM has evolved significantly since its inception in the late 20th century, driven by the need to manage complex product data and workflows. CAD systems have also undergone substantial advancements, transitioning from basic 2D drafting tools to sophisticated 3D modeling and simulation platforms.

Previous attempts at integrating PLM and CAD systems faced numerous challenges, such as data incompatibility and lack of real-time synchronization. Early integrations often required manual data transfers, which were time-consuming and prone to errors. However, technological advancements have paved the way for more seamless and automated integration solutions.

Objective of Integration

The primary goal of integrating PLM systems with CAD software is to create a cohesive and efficient product development environment. Key benefits of this integration include:

- Improved Workflow Efficiency: Automated data transfers and real-time updates eliminate manual processes and reduce downtime.

- Enhanced Collaboration: Teams can work together more effectively with centralized access to up-to-date design data.

- Streamlined Product Development: Consistent and accurate data management accelerates the design-to-manufacturing process.

Technical Aspects of Integration

Integration Techniques

There are several methods for integrating PLM systems with CAD software, each with its own advantages and considerations:

- Direct APIs: Application Programming Interfaces (APIs) allow direct communication between PLM and CAD systems, facilitating seamless data exchange and automation.

- Middleware Solutions: Middleware acts as an intermediary layer that translates and synchronizes data between PLM and CAD, providing flexibility and scalability.

- Custom Scripts: Tailored scripts can be developed to handle specific integration requirements, offering a high degree of customization for unique workflows.

Data Synchronization

Effective data synchronization is crucial for maintaining data consistency and integrity between PLM and CAD systems. Several methods can be employed to achieve this:

Challenges: Ensuring data consistency, managing version control, and providing real-time updates are common challenges. Robust synchronization mechanisms and version management protocols are essential to address these issues.

Security and Compliance

Security is a paramount concern in PLM and CAD integration. Protecting sensitive design data and ensuring compliance with industry standards and regulations is critical. Integrations should incorporate encryption, access controls, and audit trails to safeguard data integrity and confidentiality.

Practical Applications and Case Studies

Industry Applications

Various industries benefit significantly from the integration of PLM and CAD systems, enhancing their product development capabilities:

- Automotive: Integration streamlines the design and manufacturing processes, allowing for rapid prototyping and efficient production.

- Aerospace: Ensuring precise and accurate design data management is crucial for compliance and safety in aerospace engineering.

- Consumer Goods: Accelerated time-to-market and improved product quality are key advantages for consumer goods manufacturers.

Case Studies

Numerous real-world examples demonstrate the successful integration of PLM and CAD systems, showcasing measurable improvements and overcoming specific challenges.

Software Solutions

Several popular software solutions support PLM and CAD integration, each offering unique features and functionalities:

- Siemens Teamcenter: Provides comprehensive PLM capabilities with seamless CAD integration, enhancing collaboration and data management.

- PTC Windchill: Offers robust PLM functionality, including real-time synchronization with leading CAD systems.

- Dassault Systèmes ENOVIA: Integrates with the CATIA CAD system to deliver a unified platform for product design and lifecycle management.

Future Trends and Considerations

Technological Advancements

Emerging technologies are set to revolutionize PLM and CAD integration, introducing new possibilities for product development:

- Artificial Intelligence (AI): AI-driven tools can automate routine tasks, optimize designs, and enhance decision-making processes.

- Machine Learning (ML): ML algorithms can analyze vast amounts of data to identify patterns and improve predictive maintenance.

- Internet of Things (IoT): IoT-enabled devices can provide real-time data for more informed and responsive design adjustments.

Best Practices for Implementation

For businesses considering the integration of PLM and CAD systems, the following recommendations can ensure successful implementation:

- Define Clear Objectives: Establish specific goals and measurable outcomes for the integration process.

- Select the Right Tools: Choose software solutions that align with your business needs and technical requirements.

- Ensure Data Integrity: Implement robust data synchronization and version control mechanisms to maintain data consistency.

- Invest in Training: Provide comprehensive training for users to maximize the benefits of the integrated systems.

Conclusion

In summary, the integration of PLM systems with CAD software is a pivotal step toward achieving seamless product lifecycle management. It enhances workflow efficiency, fosters collaboration, and streamlines product development processes. As emerging technologies continue to evolve, the potential for even more advanced and real-time integration solutions grows, offering exciting opportunities for businesses to innovate and remain competitive. Companies are encouraged to explore these integration opportunities to fully leverage the capabilities of both PLM and CAD systems.

Also in Design News

Embracing Data-Driven Design: Revolutionizing Product Development with Advanced Analytics

October 02, 2025 12 min read

Read More

Design Software History: Early Electronics CAD: From Manual Drafting to Algorithm-Driven Design and Its Impact on the Industry

October 02, 2025 10 min read

Read More

Cinema 4D Tip: Streamline Scene Management in Cinema 4D with the Stage Object

October 02, 2025 3 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …