Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Introducing BricsCAD Mechanical 2023.2: Enhancements for Improved Performance and Productivity

August 18, 2023 2 min read

BricsCAD Mechanical V23.2 offers users a comprehensive set of tools and features that streamline the design and drafting process. It can help you achieve better results with less effort, thanks to improved performance and productivity.

Enhanced Stability and Performance for Mechanical Design

With BricsCAD, engineers can now make their design process more efficient and accurate. This version focuses on stability and performance, with additional requested enhancements to support mechanical design processes.

Users can now customize BOM content by adding cycle and availability data of parts on hand, ordered, or located in the assembly workbench. The BOM Manager allows users to easily search, sort, and organize line items in the BOM for convenient reference when reviewing assemblies prior to production or shipping out parts orders from inventory stockroom shelves.

New Welder Toolkit

The new welder toolkit permits engineers to create several weld beads at once instead of a one at a time approach, reducing the time needed for preparing weldments for production purposes. This also ensures accuracy during fabrication operations such as welding inside structures with complex geometries like tanks or pressure vessels where precise measurements are critical from an engineering standpoint due to safety concerns. This applies to industrial applications such as gas pipelines, where pressure levels can be hazardous if any kind of leakage occurs due to misalignment between two parts being joined together by welding techniques commonly used in many industries today like shipbuilding or automotive manufacturing plants around the world. These industries heavily rely on 3D modeling tools like CAD programs, which allow them to simulate every step before committing resources into actual physical manufacturing processes that require high initial investments upfront and ongoing maintenance costs during operational life cycles. These requirements lead into economic requirements when designing new products that will eventually go into market competition against similar products produced by other companies.

Thanks to advances in technology, capabilities made possible by recent leaps forward in computational power of computing devices used nowadays, even small companies can access powerful programs that remain cost-effective, functional, and economical in terms of sacrificing quality standards and the end user experience.\

Object Attachment Feature

The Object Attachment Feature makes it easy to add symbols that remain associated with geometry when moved. Models, views, exploded representation, extractable paper space, user-defined disassembly/maintenance steps, and communication are made easy, making sure everyone has a clear understanding of the instructions provided for doing specific tasks correctly. This ensures that everyone knows exactly what is expected in terms of deliverables and the timeline agreed upon for completion date. Close monitoring of progress reports is submitted regularly to supervisors, keeping track of progress as the situation constantly changes and goes through various modifications and updates that are needed whenever changes occur during the process itself until the final version is released for public consumption.

Also in Design News

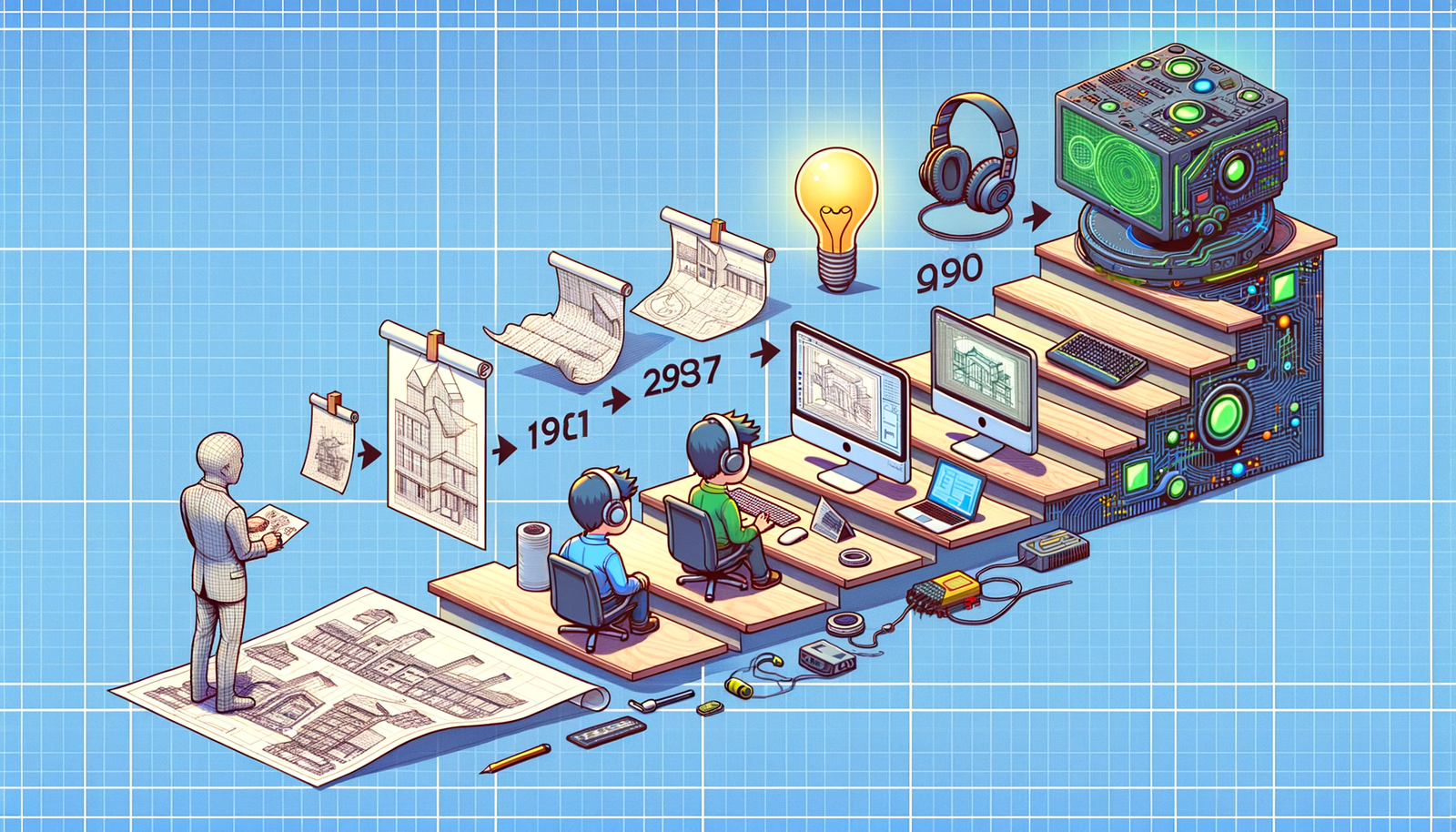

Design Software History: Evolution of Rendering Techniques in Architectural Design: From Early Graphics to AI-Driven Solutions

January 15, 2025 9 min read

Read More

Harnessing AI for Transformative Architectural Design Innovation

January 14, 2025 6 min read

Read More

Bluebeam Tip: Enhancing Bluebeam Revu Performance: Key Preference Adjustments

January 14, 2025 1 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …