Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Harnessing Cyber-Physical Systems for Next-Generation Design Automation

December 07, 2024 6 min read

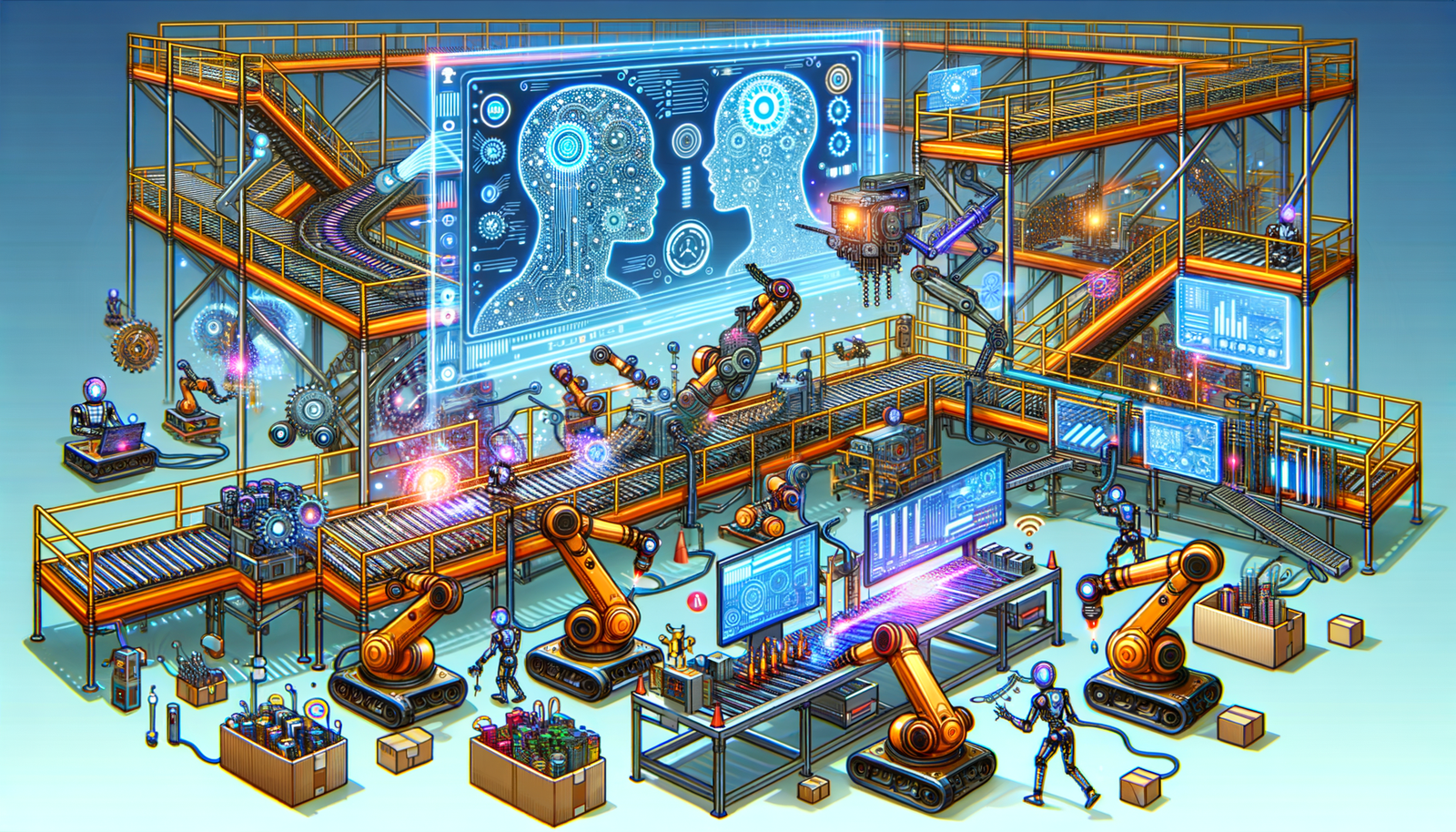

Introduction to Cyber-Physical Systems in Design Automation

In the rapidly evolving landscape of modern technology, Cyber-Physical Systems (CPS) have emerged as a revolutionary concept, fundamentally transforming the way we approach design automation. CPS represents the seamless integration of computation, networking, and physical processes, creating systems where physical and software components are deeply intertwined, each operating on different spatial and temporal scales, and exhibiting multiple and distinct behavioral modalities. This fusion enables real-time interaction between the physical and digital worlds, allowing for advanced monitoring, coordination, control, and integration of previously disparate systems. In modern design environments, the importance of CPS cannot be overstated. They provide the foundational architecture for developing systems that are more efficient, reliable, and capable of complex functionalities, thereby pushing the boundaries of what's possible in fields such as manufacturing, transportation, healthcare, and infrastructure.

The evolution of CPS in design automation marks a significant shift from the era of basic digital systems to highly integrated and sophisticated platforms. Initially, design automation relied on standalone digital systems that performed specific tasks with minimal interaction or adaptability. These systems were limited in scope and lacked the ability to respond dynamically to changing environments or inputs. However, with advancements in sensor technology, data processing, and network connectivity, there has been a transition towards integrating these elements into a cohesive CPS framework. This evolution has enabled systems to not only perform complex computations but also interact with the physical environment in real time. The result is a more responsive and adaptive design process that can accommodate the increasing complexity and demands of modern engineering projects.

Advantages of Using CPS in Design Automation

One of the most significant advantages of integrating Cyber-Physical Systems into design automation is the enhancement of real-time decision making and response improvement. CPS allows for instantaneous feedback between the physical components and computational algorithms, enabling systems to adapt rapidly to new data or environmental changes. This real-time feedback loop is crucial in applications where timing and precision are critical. For instance, in automated manufacturing processes, CPS can adjust machinery operations on-the-fly to correct deviations or optimize performance, thereby reducing errors and increasing efficiency. The ability to make immediate decisions based on live data ensures that systems remain robust and can maintain optimal functionality even under varying conditions.

Another advantage is the optimization of resource utilization. CPS facilitates the efficient management of resources by providing detailed insights into system operations and identifying areas where improvements can be made. This includes minimizing waste, reducing energy consumption, and streamlining production schedules. By leveraging data analytics and predictive modeling, CPS can forecast demand, adjust workflow accordingly, and ensure that resources are allocated where they are needed most. This not only leads to cost savings but also contributes to sustainable practices by reducing the environmental footprint of operations. In essence, CPS enables organizations to do more with less by maximizing the efficiency of every aspect of the design and production process.

Furthermore, CPS promotes boosted collaboration and communication across different disciplines and stakeholders involved in the design automation process. The interconnected nature of CPS ensures that information is seamlessly shared among all components and participants, breaking down traditional silos. This enhanced communication fosters a more collaborative environment where engineers, designers, and other professionals can work together more effectively. It enables cross-disciplinary teams to integrate their expertise, leading to innovative solutions that might not have been possible in a more fragmented system. By facilitating better coordination and knowledge sharing, CPS contributes to a more cohesive and efficient design process that leverages the full spectrum of available expertise.

- Enhanced transparency: Real-time data sharing keeps all stakeholders informed.

- Improved coordination: Synchronization of processes across different departments.

- Innovation acceleration: Collaborative problem-solving leads to creative solutions.

Challenges in Implementing CPS in Design Automation

Despite the significant benefits, implementing Cyber-Physical Systems in design automation comes with its own set of technical complexities and integration issues. The primary challenge lies in the successful interfacing between physical components and digital controls. This requires seamless communication protocols and interoperability standards that can handle the intricacies of both domains. Integrating legacy systems with new CPS technologies can be particularly problematic, as older equipment may not support the necessary connectivity or data exchange mechanisms. Additionally, ensuring real-time performance and reliability demands sophisticated system architectures and high-speed processing capabilities. These technical hurdles necessitate a deep understanding of both the physical processes and the computational algorithms that govern them, often requiring specialized expertise and significant development efforts.

Another major concern is the security risks and privacy concerns associated with CPS. The interconnected nature of these systems makes them susceptible to cyber threats, including hacking, data breaches, and malicious attacks that can disrupt operations or compromise sensitive information. The consequences of such security incidents can be severe, ranging from financial losses to physical damage and safety hazards. Protecting CPS requires robust cybersecurity measures, including encryption, authentication protocols, and constant monitoring for vulnerabilities. Moreover, as these systems often handle personal or proprietary data, privacy issues become paramount. Compliance with regulations such as GDPR and ensuring user consent and data protection add additional layers of complexity to the implementation of CPS.

- Vulnerability to attacks: Increased entry points for potential cyber threats.

- Data protection: Challenges in safeguarding sensitive information.

- Regulatory compliance: Navigating complex legal requirements.

Lastly, organizations face economic and infrastructural barriers when adopting Cyber-Physical Systems. The initial investment required for CPS can be substantial, encompassing costs for new hardware, software development, and personnel training. Small and medium-sized enterprises may find these expenses prohibitive, especially when the return on investment is not immediately apparent. Additionally, existing infrastructures may need significant modifications or upgrades to support CPS integration, leading to potential downtime and further costs. Organizations must also consider the long-term maintenance and updating of these systems, which can add to the financial burden. Therefore, careful planning, budgeting, and strategic justification are essential to overcome these economic challenges and ensure that the adoption of CPS is both feasible and beneficial in the long run.

Future Opportunities and Trends

The future of Cyber-Physical Systems in design automation is poised for significant advancements, particularly with the development of more sophisticated design automation tools. The integration of AI and machine learning into CPS is set to revolutionize how design processes are conceived and executed. AI algorithms can enhance CPS by providing advanced data analysis capabilities, predictive modeling, and autonomous decision-making. Machine learning enables systems to improve over time by learning from data patterns and outcomes, leading to increased efficiency and innovation. This fusion allows for the creation of highly adaptable systems that can respond to unforeseen challenges and optimize performance without constant human oversight. As AI continues to evolve, its synergy with CPS will unlock new possibilities in automation and intelligent system design.

Another promising trend is the expansion of CPS applications in various industries. Sectors such as automotive, aerospace, and consumer electronics are increasingly adopting CPS to enhance their products and services. In the automotive industry, CPS is instrumental in developing advanced driver assistance systems (ADAS) and autonomous vehicles, where real-time processing and interaction with the physical environment are crucial. Aerospace applications leverage CPS for flight control systems, navigation, and monitoring of aircraft health. In consumer electronics, CPS enables the creation of smart devices that interact seamlessly with users and other devices, providing intuitive and enhanced functionalities. The versatility of CPS allows it to be tailored to the specific needs of different industries, driving innovation and competitiveness across the board.

Emerging technologies such as quantum computing are set to have profound implications for CPS. Quantum computing offers exponentially greater processing power compared to classical computing, which can be leveraged to solve complex problems and simulations that are currently intractable. Incorporating quantum computing into CPS could enable unprecedented levels of data analysis and system optimization. For instance, it could facilitate real-time processing of vast datasets for predictive maintenance, energy optimization, or design simulations. While still in the early stages of development, the potential integration of quantum computing with CPS represents a significant opportunity for future advancements. Alongside developments in communications technologies and materials science, these trends point towards a future where CPS are more powerful, efficient, and integral to design automation than ever before.

Conclusion

In summary, Cyber-Physical Systems are transforming modern design automation by enabling a level of integration and intelligence that was previously unattainable. The synergetic combination of computational algorithms with physical processes allows for systems that are more adaptive, efficient, and capable of meeting the complex demands of today's industries. While challenges exist—such as technical complexities, security risks, and economic barriers—the potential benefits of CPS make them a compelling avenue for ongoing investment and development. Addressing these challenges requires a concerted effort in research, the adoption of robust security measures, and a willingness to innovate and adapt.

The future impact of CPS on the design industry is poised to be profound. As we embrace these technologies, we can expect to see not only improved efficiency and productivity but also a surge in creativity and innovation. Organizations that invest in and adopt CPS will be better positioned to navigate the complexities of modern markets, respond to emerging trends, and deliver cutting-edge solutions. Ultimately, the integration of Cyber-Physical Systems represents not just an incremental improvement but a paradigm shift in how we approach design automation, offering a pathway toward a more connected, intelligent, and dynamic technological landscape.

Also in Design News

Cinema 4D Tip: Structured Content Browser Workflow for Cinema 4D Asset Management

January 07, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …