Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Harnessing Advanced Materials: Revolutionizing Design Software for the Future

October 05, 2024 8 min read

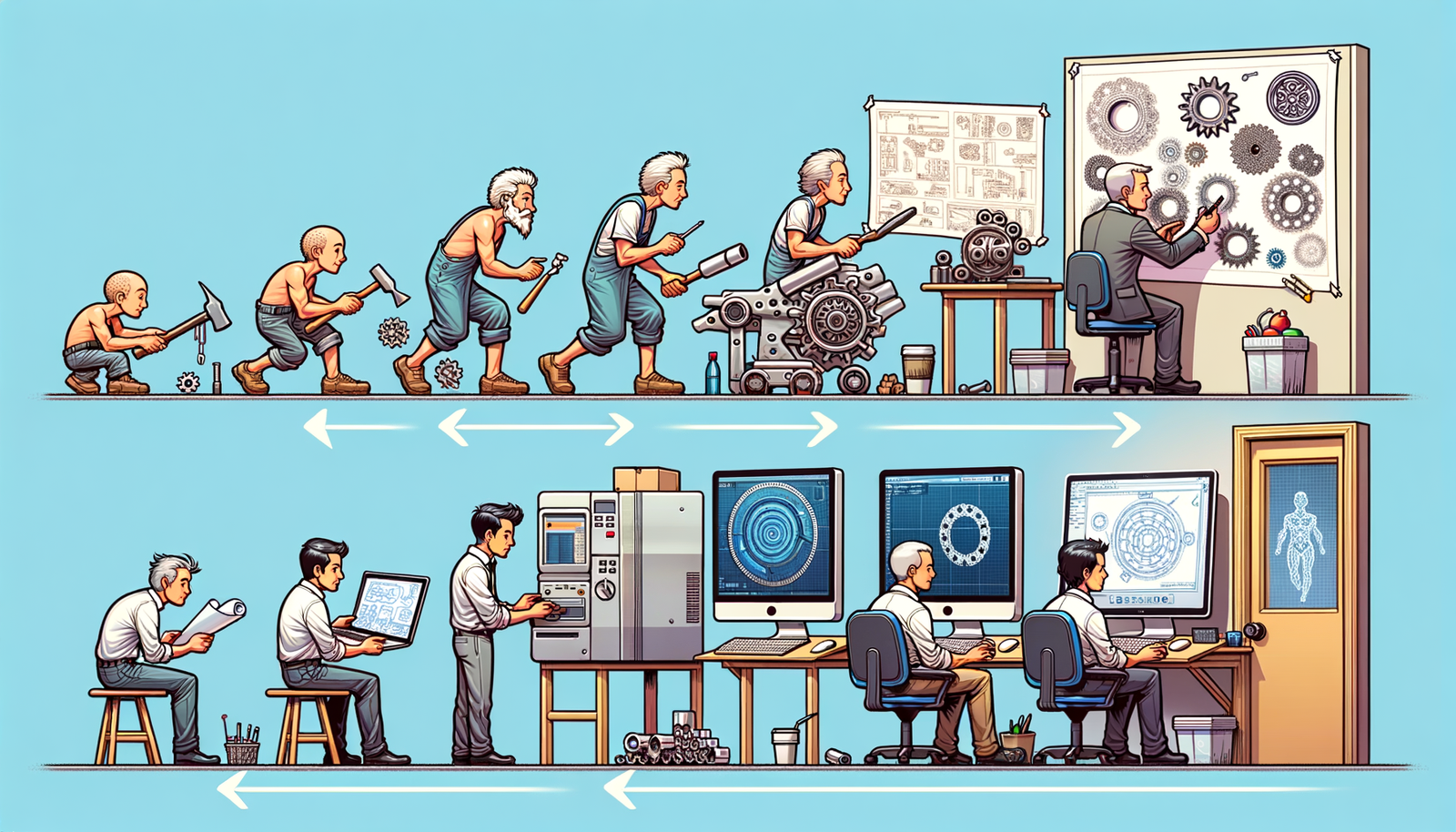

Introduction to Advanced Materials in Design

The advent of **advanced materials** has ushered in a new era in the field of design, fundamentally altering how designers conceptualize and realize their projects. These materials, characterized by enhanced properties and functionalities that surpass those of traditional substances, have become integral in addressing the complex demands of modern engineering and architecture. Their significance lies not only in their superior performance but also in their ability to inspire innovative solutions that were once considered unattainable. The integration of advanced materials into design processes has necessitated the evolution of design software, which now plays a pivotal role in modeling, simulating, and optimizing these materials for various applications. Design software has evolved from simple drafting tools to sophisticated platforms that can handle the intricacies of advanced materials. By incorporating extensive material databases and predictive simulation capabilities, these tools enable designers to explore the full potential of advanced materials. The **historical context** reveals that material innovation has always driven design trends. For instance, the transition from iron to steel in the 19th century revolutionized architecture, leading to the construction of skyscrapers and expansive bridges. Similarly, the development of plastics in the 20th century opened new avenues in product design due to their versatility and cost-effectiveness. Today, advanced materials like smart materials, biomaterials, and nanomaterials are not only influencing design trends but also challenging designers to rethink traditional methodologies. The **significance of advanced materials** in modern design cannot be overstated. They offer solutions to contemporary challenges such as sustainability, efficiency, and customization. The role of design software in this context is crucial, as it provides the necessary tools to integrate these materials seamlessly into projects. By simulating real-world conditions and material behaviors, designers can predict outcomes, optimize performance, and reduce the need for physical prototyping. This synergy between advanced materials and design software is propelling industries forward, fostering innovation, and setting new standards in design excellence.Smart Materials

**Smart materials** represent a revolutionary class of advanced materials that can respond dynamically to environmental stimuli such as temperature, pressure, moisture, and electric or magnetic fields. These materials have the inherent capability to alter their properties in a predictable and controllable manner, making them invaluable in creating responsive and adaptive designs. Examples of smart materials include **shape-memory alloys**, which can return to their original shape after deformation when exposed to specific temperatures, and **piezoelectric materials**, which generate an electric charge in response to mechanical stress. In architecture, smart materials are being utilized to develop buildings that adapt to environmental conditions, enhancing energy efficiency and occupant comfort. For instance, windows made from electrochromic glass can adjust their transparency to control light and heat transmission, reducing the reliance on heating and cooling systems. In product design, shape-memory polymers are used to create self-healing materials that extend the lifespan of consumer goods. The automotive industry employs piezoelectric materials in sensors and actuators to improve vehicle performance and safety. To effectively harness the potential of smart materials, design software has incorporated advanced simulation tools that model their behavior under various conditions. These tools enable designers to: - **Predict material responses** to changes in the environment. - **Optimize material placement** within a design for maximum efficiency. - **Integrate control systems** that manage material behavior in real-time. By providing a virtual testing ground, design software allows for the exploration of innovative applications without the risks and costs associated with physical prototypes. The ability to simulate and adjust designs iteratively ensures that smart materials are used to their fullest potential, leading to products and structures that are both cutting-edge and reliable.Biomaterials

**Biomaterials** are materials derived from natural sources or engineered to interact with biological systems for medical purposes. In the broader context of design, biomaterials encompass any material that is biocompatible or biodegradable, offering environmentally friendly alternatives to traditional materials. The use of biomaterials aligns with the growing emphasis on sustainability and **eco-friendly design practices**, addressing the global imperative to reduce environmental impact. Biomaterials are making significant inroads in various design fields: - **Architecture**: The integration of natural materials like bamboo, cork, and mycelium offers sustainable building solutions with unique aesthetic qualities. - **Product Design**: Biodegradable plastics and composites reduce waste and pollution, particularly in single-use products and packaging. - **Medical Devices**: Biocompatible materials enable the creation of implants and prosthetics that interact favorably with human tissue. Design software plays a crucial role in facilitating the use of biomaterials by providing tools that assess material properties, environmental impact, and lifecycle performance. Features include: - **Material selection modules** that highlight sustainable options. - **Lifecycle analysis tools** to evaluate the environmental footprint. - **Simulation of biodegradation processes** to predict product longevity. By leveraging these capabilities, designers can make informed decisions that balance functionality, aesthetics, and sustainability. The impact of biomaterials on design software capabilities underscores the industry's commitment to environmental stewardship and innovation.Nanomaterials

At the forefront of material science are **nanomaterials**, substances engineered at the atomic or molecular scale, typically less than 100 nanometers in size. These materials exhibit extraordinary physical, chemical, and mechanical properties that differ significantly from their bulk counterparts due to quantum effects and a high surface-area-to-volume ratio. **Nanomaterials** such as carbon nanotubes, graphene, and nanoparticles have opened new possibilities in enhancing product performance across various industries. Incorporating nanomaterials into design presents unique challenges and opportunities. Their exceptional strength, electrical conductivity, and thermal properties make them ideal for applications requiring high performance in compact forms. For example: - **Electronics**: Graphene's superior conductivity and flexibility enable the development of thinner, more efficient electronic devices. - **Medical Devices**: Nanoparticles are used for targeted drug delivery systems, improving treatment efficacy and reducing side effects. - **Aerospace**: Carbon nanotubes reinforce composite materials, resulting in lighter and stronger components. Design software must accommodate the intricacies of nanomaterials by offering advanced modeling and simulation capabilities. Innovations in this area include: - **Molecular dynamics simulation** to predict nanomaterial interactions. - **Multiscale modeling** that bridges the gap between nanoscale properties and macroscopic performance. - **Integration with material characterization data** to enhance accuracy. The **implications for product durability and performance** are profound. By accurately simulating nanomaterial behavior, designers can optimize structures for maximum strength-to-weight ratios, thermal management, and electrical performance. This level of precision fosters innovation, enabling the development of products that meet stringent performance criteria while pushing the boundaries of what's possible.Enhancements in Design Software Capabilities

The integration of advanced materials into design processes has propelled significant enhancements in design software capabilities. These advancements are essential to meet the complex requirements associated with modeling, simulating, and manufacturing products utilizing these sophisticated materials.Material Libraries and Simulation Tools

Modern design software boasts extensive **material libraries** that include detailed properties of advanced materials. These libraries provide designers with access to critical information such as mechanical properties, thermal conductivity, electrical characteristics, and environmental impact. The integration of **simulation tools** enhances the design process by allowing real-time analysis and visualization of material behavior under various conditions. Key features of these tools include: - **Finite Element Analysis (FEA)**: Enables stress, strain, and deformation analysis. - **Computational Fluid Dynamics (CFD)**: Assists in evaluating thermal and fluid interactions. - **Multiphysics Simulation**: Allows simultaneous analysis of multiple physical phenomena. By utilizing these tools, designers can: - **Optimize material selection** based on performance criteria. - **Predict failure points** and improve product reliability. - **Reduce prototyping costs** by validating designs virtually. The combination of comprehensive material libraries and advanced simulation tools empowers designers to make informed decisions, enhancing efficiency and innovation in the design process.Integration with Manufacturing Techniques

The seamless **integration of design software with advanced manufacturing techniques** is crucial for bringing complex designs to fruition. Software platforms now offer compatibility with processes such as **3D printing**, **CNC machining**, and **additive manufacturing**, which are essential for fabricating components made from advanced materials. Benefits of this integration include: - **Direct file transfer**: Simplifies the transition from design to production. - **Real-time manufacturability analysis**: Identifies potential issues early in the design process. - **Customization capabilities**: Facilitates the production of bespoke components tailored to specific needs. Design software enables designers to make **real-time adjustments based on material properties**, ensuring that designs are optimized for the chosen manufacturing process. This integration minimizes errors, reduces production time, and enhances the overall quality of the final product.Collaboration with Material Scientists

The complexity of advanced materials necessitates a close **collaboration between designers and material scientists**. Design software platforms have evolved to support this interdisciplinary approach by providing collaborative tools and environments. Key aspects include: - **Shared databases**: Allow for the exchange of material data and research findings. - **Collaborative workspaces**: Enable real-time collaboration on design projects. - **Feedback mechanisms**: Instill a feedback loop to refine design processes and material applications. This collaboration leads to: - **Enhanced material utilization**: Leveraging expert knowledge to maximize material performance. - **Accelerated innovation**: Combining expertise to develop novel solutions. - **Improved education and training**: Facilitating knowledge transfer between disciplines. By fostering collaboration, design software helps bridge the gap between theoretical material science and practical design applications, resulting in more innovative and effective products.Future Perspectives and Challenges

The ongoing evolution of advanced materials presents both exciting opportunities and significant challenges for the design industry. As new materials emerge, design software must continue to adapt to accommodate their unique properties and potential applications.Emerging Trends and Potential Impact

Emerging trends in advanced materials include: - **Metamaterials**: Engineered to have properties not found in naturally occurring materials, such as negative refractive indices. - **Self-healing materials**: Capable of autonomously repairing damage, enhancing longevity. - **Biomimetic materials**: Inspired by nature’s designs, offering efficiency and sustainability. The potential impact on design software includes: - **Enhanced simulation capabilities**: To model complex and novel material behaviors. - **Expanded material databases**: Incorporating new materials as they are developed. - **Integration with artificial intelligence**: Utilizing machine learning to optimize material selection and design processes. Designers will be able to create products with unprecedented performance characteristics, pushing the boundaries of innovation.Challenges of Integrating Advanced Materials

Integrating advanced materials into established design workflows presents several **challenges**: - **Compatibility issues**: Existing software may not support the unique properties of new materials. - **Learning curves**: Designers need to acquire new knowledge and skills to work effectively with advanced materials. - **Cost considerations**: Advanced materials and the software required to design with them can be expensive. To address these challenges, it is important to: - **Continuously update software**: Ensuring compatibility with the latest materials. - **Provide training and resources**: Helping designers adapt to new technologies. - **Foster collaboration**: Engaging interdisciplinary teams to share expertise. By proactively addressing these challenges, the industry can facilitate the seamless integration of advanced materials into the design process.The Importance of Continuous Innovation in Software Development

The rapid pace of material advancement necessitates a commitment to **continuous innovation in software development**. Design software must evolve in tandem with material science to remain relevant and effective. Essential strategies include: - **Regular software updates**: Incorporate new materials and simulation capabilities. - **User-centric design**: Develop intuitive interfaces that cater to the needs of designers. - **Collaboration with industry experts**: Engage with material scientists and engineers to stay abreast of emerging trends. An **adaptive, forward-thinking approach** ensures that design software remains a powerful tool for innovation. By embracing change and prioritizing development, software companies can empower designers to fully leverage the capabilities of advanced materials, leading to products and structures that meet the demands of an ever-evolving world.Also in Design News

Harnessing Holographic Technology for Revolutionary Design Visualization and Interaction

November 25, 2024 4 min read

Read More

Design Software History: The Evolution and Impact of Siemens NX in Bridging Design and Manufacturing

November 25, 2024 3 min read

Read More

ZBrush Tip: Optimizing Sculpting Workflow with ZBrush Reference Views

November 24, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …