Your Cart is Empty

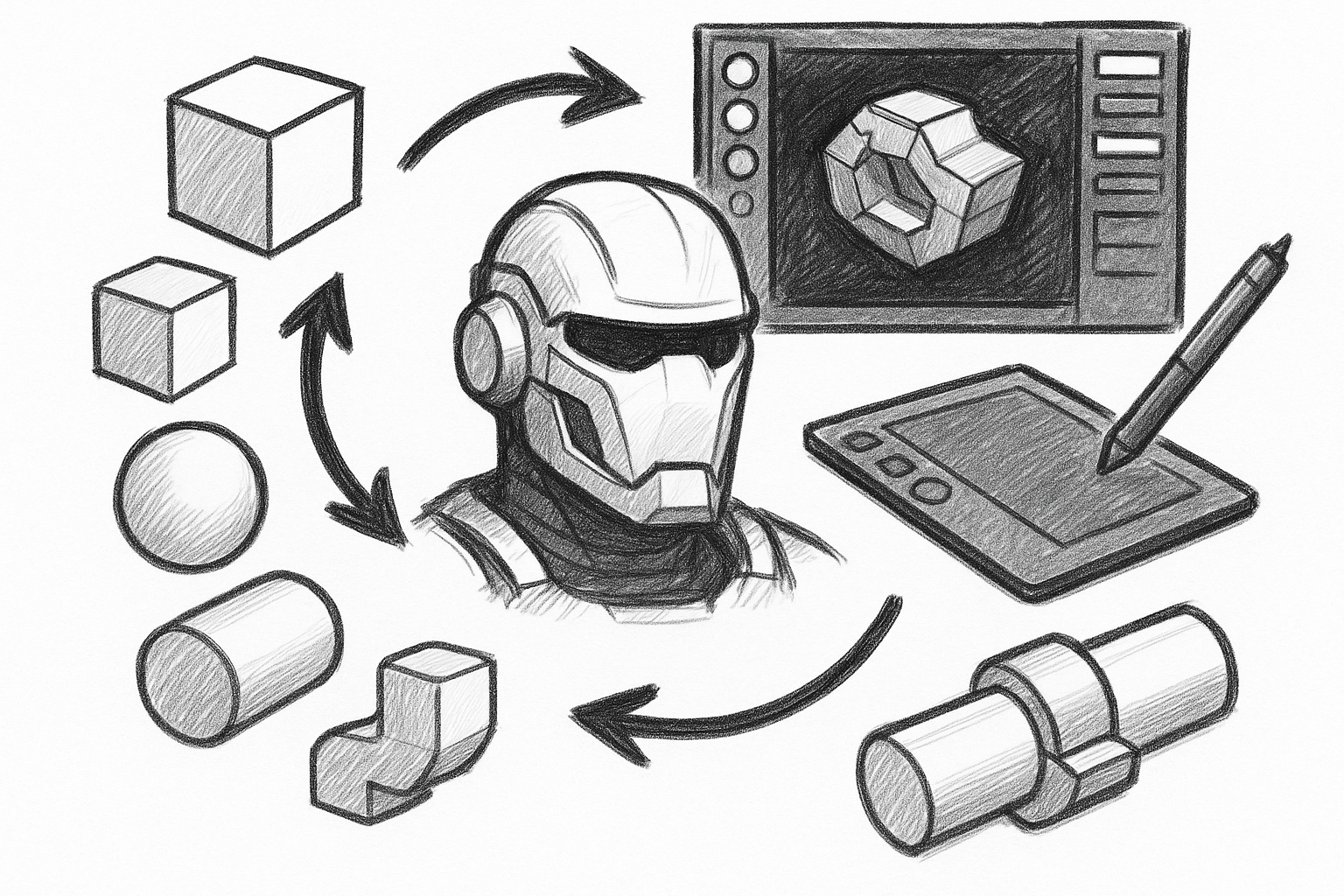

ZBrush can be a production-ready hard surface system when you fuse poly-modeling, precise booleans, feature-driven panelization, and scalable instancing. Below are five interlocking techniques that turn blockouts into crisp, manufacturable forms quickly and repeatably.

ZModeler for Precision Blockouts and Controlled Topology

Treat ZModeler as your parametric stand-in: it offers decisive topology edits without leaving ZBrush. The goal is to build confident, dimensionally coherent shapes that survive refinement. Work with editability in mind—polygroups and crease rules serve as your non-destructive rails.

Goals

- Construct parametric-like forms directly in ZBrush, avoiding round-trips to a traditional DCC until final handoff.

- Maintain editability via Polygroups, Crease by Angle/PolyGroup, and a predictable edge hierarchy.

Core actions to master

Learn the behavior differences so your operations are intentional:

- QMesh versus Extrude: QMesh welds when faces meet and intelligently snaps to neighbors; Extrude adds thickness without welding for layered shells or spacers.

- Inset (region versus poly): Region preserves islands and gives uniform offsets; Poly isolates insets per face for tiling microforms.

- Bevel: Insert control loops for chamfer-ready edges and transitional steps before smoothing.

- Bridge: Span holes and connect islands; use two-hole bridging to form ducts and tunnels cleanly.

- Slide and Spin Edges: Re-route tension lines, realign flow around corners, and fix pinching before it happens.

- Crease Edge/PG/All and Uncrease: Lock edges you intend to read as engineered, then selectively soften where needed.

Polygroup-centric workflow

Produce polygroups early and often. Group by Normals sets seam logic automatically; Group Front isolates view-facing areas for localized operations; Auto Groups simplifies multi-island selections. Because ZModeler targets can filter by polygroup, this scaffolding lets you QMesh particular plates, Bridge only selected islands, or Inset a subset of faces with precision. Polygroups also future-proof the asset for Panel Loops, KeepGroups remeshing, and crease-by-group operations.

Dynamic preview and precision

Use Dynamic Subdivision to preview hard edges without committing density. CreaseLevel establishes how many smoothing iterations ignore smoothing across creased edges; SmoothSubdiv controls the visible sharpness. Work with Gizmo 3D Snap and Align, and bring in deformers such as Bend Arc, Taper, and Twist for exact transforms. With symmetry or custom pivots, you can scale and align blockouts as though they were parametric components.

Best uses

ZModeler excels at base chassis, housings, rail systems, mechanical ribs, and chamfer-ready forms where edge control matters from the outset.

Pitfalls and fixes

- Stray micro-polys create shading potholes: isolate and purge with Delete Hidden and Close Holes, then rebuild missing spans via Bridge.

- Scale drift makes QMesh/Inset increments unpredictable: set a consistent working size and reference increment values in the ZModeler action settings.

Live Boolean + Knife/Clip/Trim for Non-Destructive Cutting

Live Boolean turns ZBrush into a fast fixture-based machining environment. Paired with Knife, Clip, and Trim, you gain a non-destructive cutting stack you can re-aim, repurpose, and duplicate.

Live Boolean setup

- Organize SubTools by boolean role: Add for keep, Subtract for cutters, Intersect for limited overlaps. Tag all cutters as Subtract to preview results in real time.

- Duplicate and repurpose primitive SubTools as reusable cutter blocks. Name them logically (Port_15mm, Vent_Slot_02) to build a quick library.

Cutting toolkit

KnifeCurve and KnifeRect perform true topology slicing and auto-assign crisp polygroups at the cut, excellent for follow-up remeshing and creasing. Clip brushes project vertices to a plane—great for planarization and corrective trimming. Trim brushes remove and remesh regions with flat fills, ideal for shaving extrusions or producing sharp terminations. Use Gizmo deformers to angle cutters precisely; Align to World or Align to Surface yields clean orthographic cuts and repeatable alignment for multi-part assemblies.

Bake and post-process

When the cut grammar is correct, Make Boolean Mesh commits the stack. For consolidated volumes, enable Remesh by Union. Post-boolean, run ZRemesher with KeepGroups and DetectEdges to recover clean quads. If you had microforms you want to preserve, store the pre-boolean mesh and Project All after remeshing to restore finer detail while keeping the new topology.

Best uses

Use this stack for ports, vents, mortises and tenons, cable channels, negative-space logos, and sight windows—features that must be crisp, aligned, and repeatable.

Pitfalls and fixes

- Thin shells may self-intersect during booleans: add temporary thickness via Extrude or inflate shells slightly, then remove or refine after baking.

- Post-boolean n-gon islands are inevitable in complex intersections: steer ZRemesher with Target PolyCount and Guides; crease by polygroups afterward to re-establish edge intent.

Edge Discipline with Creasing, Dynamic Subdiv, and ZRemesher

Hard surface perception lives or dies on edge behavior. Discipline here means your edges read as manufactured—neither muddy nor razor-harsh unless designed that way. Use creases as contracts, and treat subdivision as a preview stage until you need real density.

Crease-first strategy

Start by creasing by PolyGroup and by Angle to lock key edges. Manage CreaseLevel relative to SmoothSubdiv: a CreaseLevel of 2–3 with a SmoothSubdiv of 4–5 typically yields believable industrial corners. Where you want manufactured-but-not-knife-sharp radii, selectively uncrease or reduce CreaseLevel so smoothing rounds the edge subtly without collapsing the silhouette.

Dynamic vs real subdivision

Work in Dynamic for responsiveness and clarity. Convert to real subdivision levels only when you require sculptable resolution for surface microforms, wear, or texturing masks. Keeping Dynamic active with a clean crease scaffold protects editability far longer in the process.

ZRemesher for hard edges

Run ZRemesher with KeepGroups and DetectEdges enabled to honor seam and angle logic. Use Half or a precise Target count to steer density. Disable Adapt when you want uniformity, especially ahead of Panel Loops or heavy boolean bakes. Add ZRemesher Guides to direct loops around corner terminations and to prevent star-like poles near critical chamfers.

Beveling and rounding options

- Quick bevels with ZModeler: Inset then QMesh a control loop or two to produce predictable chamfer zones.

- Polish by Features/By Groups: Generate micro-rounds that respect creased borders, tightening readability without melting forms.

- Optionally, BevelPro (when available): Automate consistent chamfers from polygroups and angle thresholds for global pass finishing.

Best uses

Deploy this discipline for production edges that must read as machined—chamfers, safety rounds, and step-down fillets on enclosures, brackets, and frames.

Pitfalls and fixes

- Creases lost after remeshing: reapply via Crease by PolyGroup; store and reload Crease Sets before heavy operations to safeguard intent.

- Over-polishing melts edges: isolate regions with polygroups or protect with Morph Targets, and polish with conservative values focused on features.

Panelization with Panel Loops and Feature-Driven Polygroups

Panelization sells manufacturability. With Panel Loops, you convert feature maps into layered plates, gaskets, and seams that read as assembled hardware rather than monolithic sculpture.

Create feature maps

- Generate polygroups from forms using Groups by Normals to derive seam logic automatically from curvature breaks.

- Use Masking plus Group Masked for custom panel shapes. KnifeCurve is excellent for drawing high-precision boundaries that auto-polygroup on cut.

Panel Loops setup

Dial Thickness as a real-world proportion of the object’s scale, then set Bevel to manage edge read. Elevation determines whether panels are outward, inward, or centered; for shelled skins, outward elevation avoids internal interpenetrations. Use Double judiciously when you truly need both directions. Polish refines panel edges—small values maintain crispness, while higher values can over-soften if unguarded.

Layered construction

Duplicate the SubTool to create inner and outer skins with different Panel Loops, establishing layered armor or composite housings. For gaskets, grow a mask from the intended seam, convert to polygroup, and apply a Panel Loop with a narrow bevel and light polish. Slight elevation offsets between layers keep the stack legible and prevent z-fighting during renders.

Finishing passes

Polish by Groups and “crisp edge” workflows refine the manufactured read. Store a Morph Target on each panel, polish just enough to remove saw-toothing, then project back to preserve flats while maintaining tidy edges. This hybrid approach retains the machined look without sacrificing clarity in curved regions.

Best uses

Access hatches, armor plates, phone and laptop seams, UAV fuselage breaks—anywhere mechanical segmentation conveys function, maintenance access, or material layering.

Pitfalls and fixes

- Overlapping panel thickness: measure and offset elevations to avoid interpenetration; consider temporarily isolating layers to verify spacing.

- Faceted panel edges on curves: increase base mesh density before Panel Loops, or remesh with ZRemesher and re-establish loops for smoother boundaries.

Kitbashing and Repetition with IMM, NanoMesh, and ArrayMesh

Detail density must be controlled and legible. With IMM, NanoMesh, and ArrayMesh, you scale details non-destructively, preserve responsiveness, and reinforce functional logic across the design.

IMM-based detailing

- Build or curate IMM libraries for bolts, vents, cable anchors, knurl patterns, and sliders. Establish naming and sizing conventions for rapid retrieval and consistent scale.

- Use Brush > Modifiers: Align to Surface to orient inserts to local normals. Enable Weld when parts must merge seamlessly. Tri-Part IMM is ideal for belt- or track-like elements that need adaptive length with consistent end caps and mid-sections.

NanoMesh for instancing

Distribute repeating details across selected polygroups while keeping the asset lightweight. Control variation via scale, angle, random seed, and offset to avoid sterile repetition. Delay conversion to real geometry until late; your viewport remains responsive, and layout revisions stay painless.

ArrayMesh for precision arrays

Use ArrayMesh for linear and radial patterns—screws around flanges, fins across heat sinks, gear teeth, or spoke patterns. You can adjust count, offset, twist, and symmetry non-destructively. Combine with Gizmo alignment to target world axes or local component frames for exact spacing.

Integration with booleans

Convert selected IMM parts into negative cutters for ports and fastener recesses, then commit with Live Boolean. Because your inserts are already dimensionally consistent, the resulting cuts inherit that precision, minimizing cleanup.

Readability and scale

Establish a “detail budget.” Vary size and spacing, and prioritize function: cluster fasteners near load paths, place vents near hot zones, and reserve negative space to prevent noise. Consider silhouette and mid-frequency rhythm before adding microforms; viewers decode design logic faster when details follow believable engineering cues.

Pitfalls and fixes

- Over-density noise: intentionally remove 20–40% of greebles; favor clusters, gradients of density, and rests of negative space.

- Orientation mistakes: always use surface normals and Gizmo alignment for consistent up-vectors; correct misaligned batches by re-projecting orientation on a temporary helper surface.

Putting it all together

Excellence in ZBrush hard surface work emerges from combining these five capabilities: ZModeler precision for blockouts, Live Boolean and cutting brushes for surgical subtraction, disciplined edges with Dynamic Subdivision and ZRemesher, feature-driven panelization with Panel Loops, and scalable instancing via IMM, NanoMesh, and ArrayMesh. Each reinforces the others; polygroups created in blockout guide booleans and panels, crease sets survive remeshing and polishing, and instanced details inherit the clean surfaces you’ve engineered upstream.

Adopt a short, repeatable practice loop to build speed and consistency:

- Block with ZModeler using polygroup scaffolding and crease logic.

- Cut with Live Boolean, Knife, Clip, and Trim while keeping cutters organized and reusable.

- Remesh and crease again, previewing with Dynamic until real density is necessary.

- Panelize with Panel Loops using measured thickness, bevel, and elevation.

- Kitbash and instance with IMM, NanoMesh, and ArrayMesh, respecting a deliberate detail budget.

When you time-box each pass, you cultivate decisiveness and avoid endless tinkering. The reward is a fast, repeatable workflow that moves from blockout to polished hard surface with confidence—and a model that reads as designed, engineered, and built with intent.