Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Exploring the Limits of Material Design with Nano-scale Simulations: Innovations and Challenges

July 16, 2024 2 min read

Introduction to Nano-scale Simulations in Material Design

Nano-scale simulations have revolutionized our understanding and capabilities in material science, offering a detailed glimpse into the atomic and molecular interactions that dictate material properties. These simulations leverage state-of-the-art computational techniques to model complex phenomena at the nanometer scale, providing insights that are critical for innovating materials with enhanced or novel properties. The evolution of simulation software, alongside advancements in computing power, has made nano-scale analysis more accessible and impactful in material design, paving the way for unprecedented innovation in the field.

Core Technologies Behind Nano-scale Simulations

The backbone of nano-scale simulations lies in computational methods such as Molecular Dynamics (MD) and Quantum Mechanics (QM). MD simulations allow scientists to study the physical movements of atoms and molecules over time, offering insights into the mechanical, thermal, and physical properties of materials. On the other hand, QM simulations provide an understanding of electronic structures and chemical properties, enabling the design of materials with specific electronic, optical, or magnetic properties.

The computational intensity of these simulations necessitates the use of supercomputing and cloud computing resources, allowing for the processing of complex calculations and large datasets that are beyond the reach of conventional computing systems. Furthermore, advancements in software technology have introduced a range of platforms specifically designed for nano-scale simulations, making these powerful tools more accessible to a broader audience of researchers and designers.

Applications and Case Studies

Nano-scale simulations are critical in the design and development of new materials and products across various industries. These applications include:

- Enhancements in mechanical properties, such as strength, flexibility, and durability, enabling the creation of more resilient and long-lasting materials.

- Innovations in electronics, including the development of semiconductors, batteries, and photovoltaic materials, which are essential for advancing technology and sustainable energy solutions.

- Breakthroughs in biocompatible materials for medical implants and devices, improving patient outcomes and the longevity of implants.

These applications underscore the transformative potential of nano-scale simulations in material design, driving forward innovations that were once considered beyond reach.

Challenges and Future Directions

Despite the advancements, nano-scale simulations face significant technical and computational challenges. The sheer computational power required to simulate materials at the atomic and molecular level is immense, demanding continuous advancements in computing technologies and methodologies. Moreover, the complexity of these simulations requires interdisciplinary collaboration, combining expertise in material science, chemistry, physics, and computer science to accurately model and interpret the behavior of materials at the nano-scale.

The future of material design with nano-scale simulations is poised for further breakthroughs, notably with the integration of AI and machine learning. These technologies promise to automate and enhance simulation processes, enabling faster and more accurate predictions of material properties. Additionally, the ongoing development of computational methods and materials science could lead to the discovery of new materials with unprecedented properties, offering limitless possibilities for innovation across all sectors of technology and industry.

Also in Design News

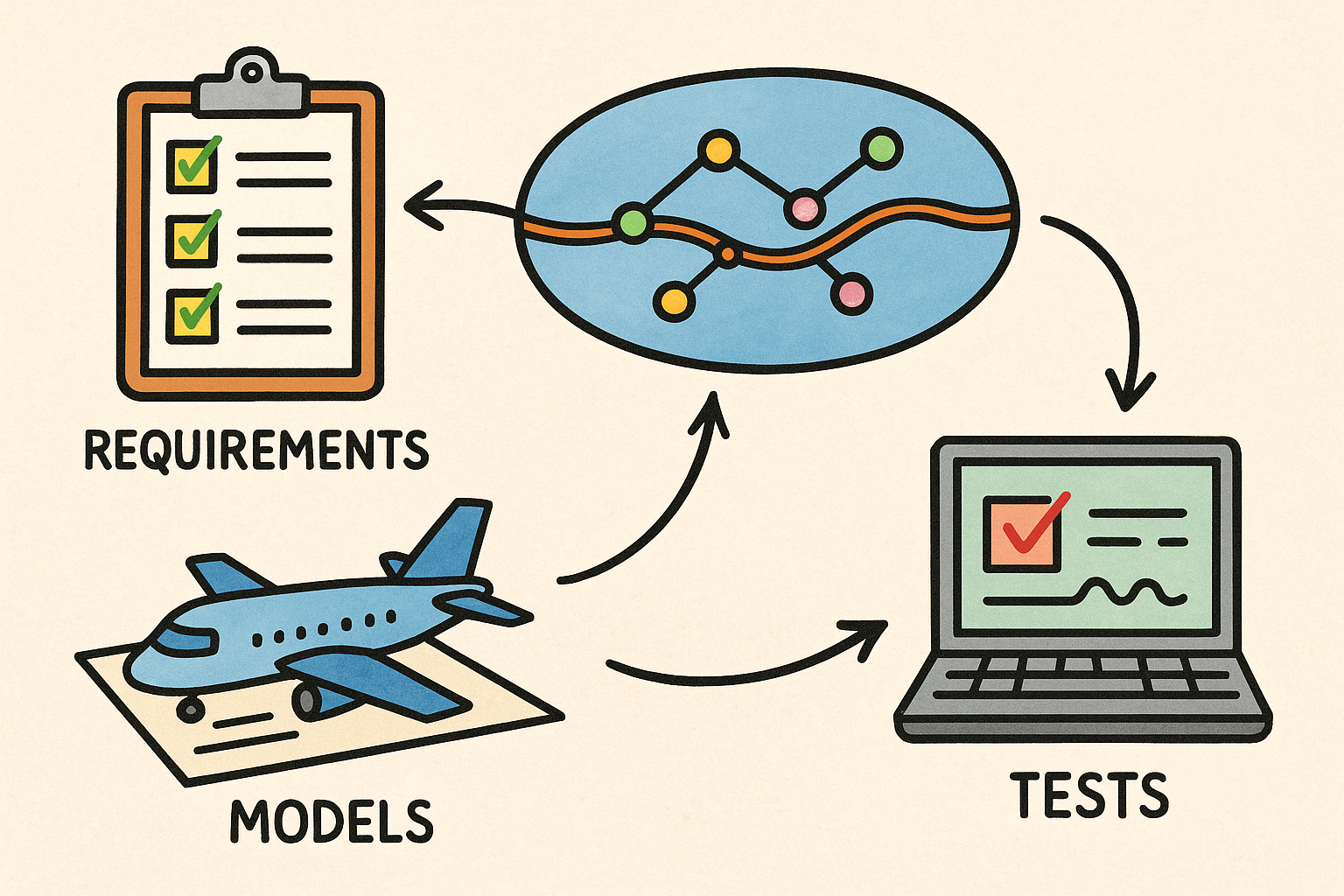

Semantics-First Digital Thread: Linking Requirements, Models, and Tests for Traceable Engineering

February 17, 2026 12 min read

Read More

Cinema 4D Tip: UV Tiling Best Practices for Cinema 4D and Redshift

February 17, 2026 2 min read

Read More

V-Ray Tip: Reflection Catcher Workflow for Photoreal Plate Integration

February 17, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …