Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Exploring Modular Design: Enhancing Flexibility and Efficiency in Product Development

July 06, 2024 2 min read

Understanding Modular Design

Modular design, in the context of product development and engineering, refers to a design approach that subdivides a system into smaller parts or modules that can be independently created and then used in different systems to drive multiple functionalities. Unlike traditional design approaches that view a product as a monolithic entity, modular design embraces flexibility and efficiency.

This approach has been successfully applied across various industries, including electronics, where manufacturers leverage modular designs for smartphones and computers, and in the automotive industry, where car manufacturers use modular platforms to streamline production and customize vehicles to meet consumer demands.

Benefits of Modular Design in Prototyping

- Speed: Modular design significantly accelerates the prototyping process by allowing engineers to rapidly assemble modules that have already been tested and validated. This reduces development time from concept to prototype.

- Cost-Effectiveness: By reusing modules across different projects, companies can achieve considerable cost reductions. This reuse also extends to the tooling and manufacturing processes, further driving down costs.

- Flexibility and Scalability: Modular design makes it easier to make changes and upgrades to a product by simply replacing or adding modules, without the need to redesign the entire system. This enhances product lifespan and facilitates scalability.

- Enhanced Testing and Quality Assurance: The isolation of components in modular design simplifies testing processes. Engineers can focus on individual modules, ensuring their functionality before integrating them into the larger system, thereby enhancing the overall quality of the product.

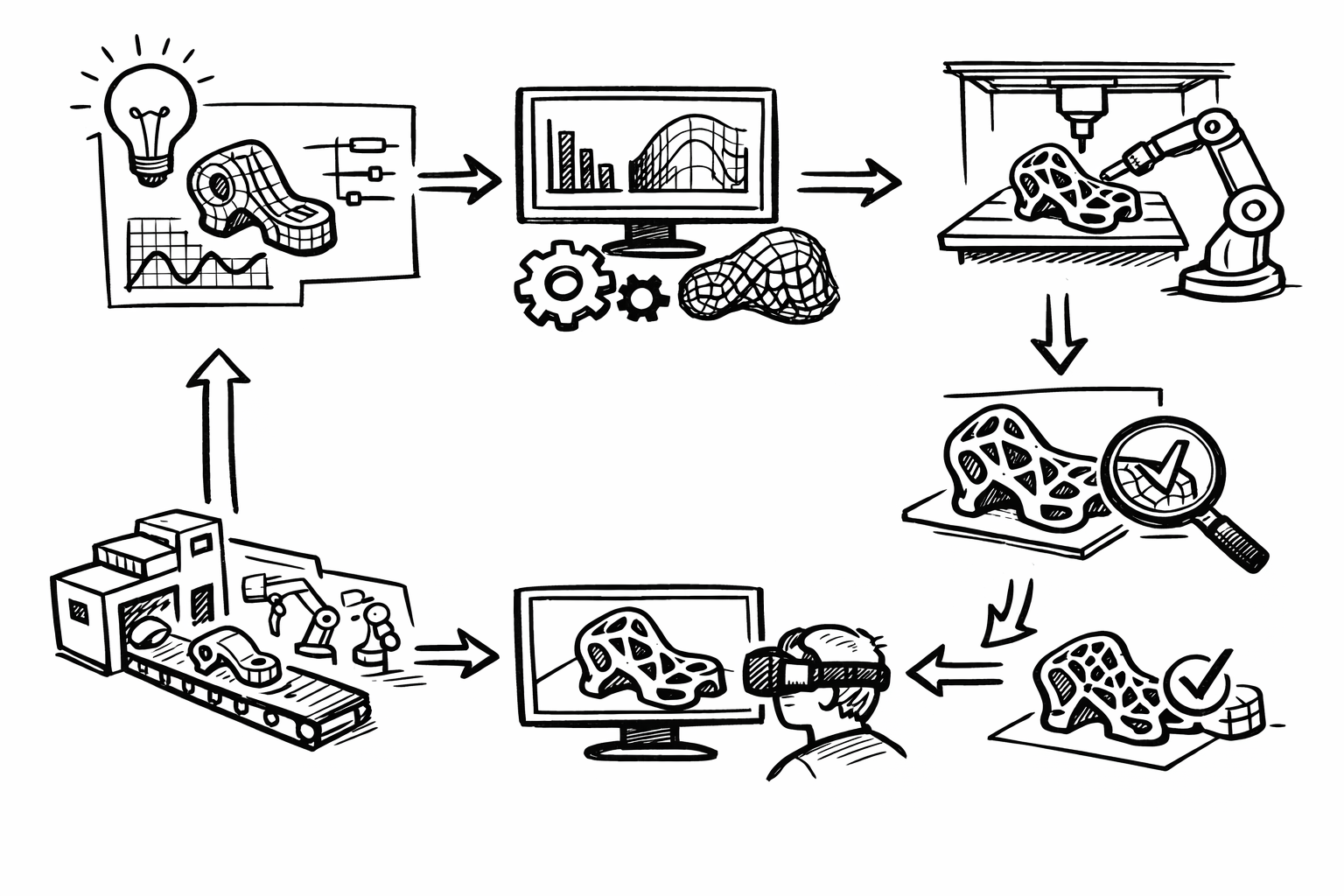

Integrating Modular Design with Rapid Prototyping Technologies

Rapid prototyping technologies such as 3D printing and CNC machining complement modular design by enabling quick production of physical prototypes from digital models. These technologies, when combined with modular design principles, have shown significant efficiency improvements and innovation in project development.

The integration of modular design in 3D printing projects has been particularly noteworthy, demonstrating how companies can reduce development cycles and foster innovation. Moreover, design software plays a crucial role in facilitating this integration, offering tools that support modular design principles, thus streamlining the prototyping process.

Future Trends and Considerations

The evolution of modular design is closely tied to emerging technologies such as AI and additive manufacturing. These advancements promise to further enhance the efficiency and flexibility of modular design approaches, leading to more innovative and adaptable product development strategies.

However, implementing modular design strategies comes with its set of challenges. Ensuring compatibility between modules and managing the complexity of systems are significant considerations that companies must address.

To adopt modular design principles effectively, organizations should consider the following best practices:

- Invest in design software that supports modular design to streamline the prototyping and development processes.

- Focus on standardization to ensure compatibility and interchangeability of modules.

- Encourage collaboration among cross-functional teams to leverage diverse expertise in the modular design process.

In conclusion, modular design has the transformative potential to make product development more adaptable, cost-effective, and innovative. As technologies continue to evolve, modular design will remain at the forefront of engineering and product development strategies.

Also in Design News

Subscribe

Sign up to get the latest on sales, new releases and more …